Rotary Indexing Washing Machine

Get Price Quote

Introduction Rotary Indexing Type cleaning machines are ideally suitable for small components, precision cleaning. These are very high productive machines. Description Takt time required is less. Compact in size. Mainly used for specific cleaning of components. Operations are performed simultaneously Effective in achieving critical cleanliness level Same side load/unload ( only one operator required) Mainly used for final cleaning Applications CRANKCASE CRANKSHAFT CAMSHAFT Features SS construction, highly reliable, low maintenance, State of the art after-sale service. Environment-friendly, aqueous cleaners. low running cost. Operator safety is built-in in the design of machine. The various options of energy for tank heating like heat pump, gas heating, heat exchanger, water heating steam heating are available. Total solution to cleaning problems.

Rotary Type Bin Cleaning Machine

770,000 Per Piece

1 Piece (MOQ)

Best Deals from Rotating Machine

Rotary Index Machine

Get Price Quote

The company is primarily engaged in the manufacturing, exporting, and supplying of the highest-grade Rotary Index Machines, all across the globe. Our Rotary Index Machines are especially designed by the experts, ensuring their higher performance at the client end. The Rotary Index Machines can be availed from us at affordable prices. Attributes : High durability High working efficiency Lower maintenance Easy installation & working

Rotating Waffle Machine

11,860 Per Piece

1 Piece (MOQ)

Rotary Sand Screening Machine

Get Price Quote

1 Piece (MOQ)

We are engaged in offering premium quality range of Rotary Sand Screens. These screens can be availed for the sieving of different materials. The screens we manufacture can be availed in an affordable range with different configurations as per the requirement of the clients. These screens can easily be operated by any skilled or unskilled person.Some important features are: Flawless performance. Easy to operate Available with different configurations

Twin Heads With Rotary Table Gantry Machine

Get Price Quote

Rotary Welding Machine

Get Price Quote

Two station Mig welding system is developed for stator of the submersible pump. The machine incorporates hydraulically operated mechanism for clamping the stator horizontally and weld the S. S. tube with M. S. end rings. This Mig welding system replaces manual Tig welding through welding automation giving excellent weld bead. This process reduces the production time dramatically to three minutes instead of thirty minutes.Since welding is carried out automatically, the dependence on a skilled operator is eliminated. Thus this is an important in the hand of submersible pump maker to improve weld quality, improve productivity and eliminate skilled man power. Applications: Many applications like welding S.S. Stator to end rings in Submersible pumps, Idler rollers for conveyors, Tig welding system for traction motor, Mig system for flex plates, silencers in automobiles, many many jobs can be easily produced using rotary welding systems.Features: These Spm's have state of art technology. They provide high production rates at less or no operator skill. Choice: Usually have one or two power sources with respective welding heads. You may choose between Tig & Mig depending on the material you may want to weld & other parameters like strength & porosity. Operation: The jobs are clamped at appropriate pressure & rotated by a geared motor. The weld torches approach the job pneumatically & weld the job circumferentially. The weld bead uniform as are voltage is used as a feed back. Salient features High Welding speeds Uniform weld bead. No operator skill Tailor made to suit customer needs. Excellent performance. Sturdy & rugged. Choice of PLC & full automation with material handling.

rotary washing machine

Get Price Quote

Rotary Washing Machines are required for machined components to be cleaned before assembly. The unique feature of this machine is that collective jobs can be cleaned in single lot. It also features a a rugged tank with a rotary spindle, having pressure jets. These Pressure Jets are stationary and the basket in between rotates, which holds the jobs to be cleaned. A thorough cleaning is achieved by pressure jets. In another way, the pressure jets revolve and the jobs remain stationary. The operator will place the jobs in the Rotary Basket and press the Cycle On PB accordingly the Pneumatic Cylinder operated Door will automatically close and the Spraying Cycle will start. After completion of the Cycle the Door will automatically open.

Rotary Welding Machine

Get Price Quote

Are you looking for a high performing rotary welding machine. If yes, then you have come to the right destination. We offer rotary welding machine, which is well known for sturdy construction and accurate designing. This long lasting rotary welding machine has programmable logic controller to achieve smooth and consistent welding.

Rotary Torso Rotation Machine

Get Price Quote

ROTARY INDEXING CHAPATI MAKING MACHINE

2,000,000 Per Set

1 Set (MOQ)

Rotary Sheet Cutting Machine

Get Price Quote

Rotary sheet cutting machine SK machines offer quality range of sheet cutting machines such as Simplex Rotary Sheet Cutting Machine and Cut to Length Machines. Rotary Sheet cutting machines have helped in widening the array of applications for our clients. All the manufacturing processes involved in their development of Rotary sheet cutting machine aptly supported by our team of dedicated engineers & technicians.

Rotary Hammer Drill Machine

Get Price Quote

10 Piece(s) (MOQ)

Rotary Indexing Machine

Get Price Quote

Being in the manufacturing business, every manufacture covets for automated operations with less cycle time. Fortunately, you can get it done instantly with the rotary indexing machine by Shiv Technology. This machine will reduce the cycle time and ultimately hike up the production volume. Its simultaneous actions deliver miraculous output within a stipulated time period. How rotary indexing machine benefits your production? The rotary indexing machine permits you to properly assemble the machine parts in an accurate and speedy way. In a fast way, it helps in the completion of work without any problem. It prevents the faulty parts for further processing. So, it ensures overall quality by allowing only those parts which are absolutely good to go. This machine efficiently performs and carry on the production process and ultimately give high productivity. It uses rotary for speedy assembling and completion of work. For oddly shaped assemblies, this machine is the best. The best part is our solutions are totally cost effective and will suit your pocket for sure. You will get all the benefits from these automated rotary machines with reduced cost. This is really a good option to assemble the parts with molding options available in these machines. Specifications Assured quality Guaranteed performance Made up of quality material Applications Prevent faulty parts after failed assembly step To ensure quality with machine parts Reduce the requirement of the workforce, so give quick results without any flaws It leads to accurate and speedy work It’s suitable to enhance productivity and cut down production cost. It’s suitable to assemble all the intricate parts within seconds at the fastest rate. Whatever size you want in your rotary machine, we, at Shiv Technology design it in an excellent way so that you can assemble all the parts in a great way. We prepare it completely adhering to your requirements. The specifications you can share with us, like, semi-automatic or fully automatic machine. Just opt for this rotary machine that is useful for completing work speedily plus recognizing the flaws in the process, if any. Order us and get it within a couple of days at your doorstep.

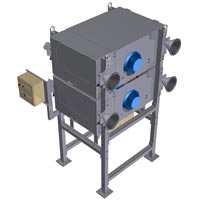

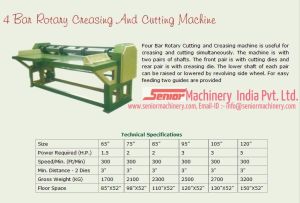

4 Bar Rotary Creasing & Cutting Machine

Get Price Quote

We offer 4 Bar Rotary Creasing & Cutting Machine. 4 Bar Rotary creasing and Cutting Machine with 4 set creasing heads & 4 sets of cutting heads with motor, pulley & belt complete. All Sizes are available.

Rotary Forging Machine

Get Price Quote

We offer high efficiency Rotary Forging Machine that is highly appreciated in the markets. Our Precision Rotary Forging Machine is designed as per the national and international quality standards. Manufactured from the advanced technology parts, our Precision Rotary Forging Machine is highly functional and easy to operate. Providing long lasting performance, our Precision Rotary Forging Machine needs low maintenance cost. We have firmly positioned ourselves as one of the prime CNC Rotary Forging Machine Suppliers based in India. What is Rotary Forging? Hot or cold forming process where the upper tool, which has a fixed angle inclination as regards the lower tool vertical axis, is used to progressively form the material into the shape wished.Incremental deformation by combining rotational movement and axial compression. Rotary Forging Advantages as Compared with Conventional Forging TECHNOLOGICAL : Greater deformations.Force Reduction (5%-20%) : less contact, less friction.Greater Dimensional Accuracy : Near Net ShapeMaterial Dimension Optimization : Burr Reduction/EliminationGreater surface finish quality (no cracks as a result of impact), incremental.Material hardening and optimized grain structureElimination of machining and welding operations.Less noisy and polluting processes (without impact and sometimes without lubricants) ECONOMIC : High flexibility —small modifications allow for new geometriesLess investment —smaller pressesLess expensive tooling —tooling geometry simplificationFewer tooling changesFewer forming stages (2-4 stages in conventional forging)Fewer energy costs

Rotary Basket Type Cleaning Machine

Get Price Quote

R 7272 CLEAN ( ROTARY TABLE SPRAY WASHERS, TOP LOADING SPRAY WASHER ) The R 7272 - Clean is an industrial quality, water based cleaning machine built for tough cleaning needs  These machines have been developed to provide effective, fast and economical cleaning.  Stainless steel construction provides a lifetime of reliable performance.  Multi-tier filtration system with disc type oil skimmer to take out the floating oil. Machine can be incorporated with following basket sizes, 250mm, 600mm, 800mm, 1000mm and upto 1300mm dia. These are well equipped as standard but also available are various optional extras to bring better cleaning quality benefits, handling and productivity who have very specific requirements above and beyond the standard specifications. Suitable for parts machining industries, general engineering and maintenance processes. Rotary Basket Type Cleaning Machine  R7272 models are designed for aqueous cleaning and degreasing of small- to medium-size work pieces. Larger parts are placed directly on the cabinet-mounted, non-retractable turntable, while small parts are batch-loaded into baskets to be processed. This front-loading industrial parts washer combines pressure, heat and an aqueous cleaning solution to clean and degrease your parts in minutes. R 7272 also feature a large-volume solution tank, which reduces the likelihood of foaming by reducing agitation through pumping action, and also helps to settle contamination. The R 7272 requires limited floor space and is ideally suited to lean manufacturing cells or maintenance and repair centers. R 7272 turntable spray washer is available in a single stage configuration wash-and-rinse stage. Design features such as low-maintenance pumps, digital temperature controllers and cycle timers are standard on R 7272 turntable parts washers. The R 7272 washers can easily be customized by choosing from a variety of available pre-engineered options.

Automatic Rotary Buffing Machine

1,500,000 Per Unit

Rotary Indexing Table Type Washing Machines

Get Price Quote

Rotary Welding Machine

Get Price Quote

rotary welding spm machine

400,000 - 800,000 Per Unit

1 Unit (MOQ)

Rotary Hopper

Get Price Quote

SMT offers a wide range of Rotary sizes, Disc formations and exit feeding options to suit most customer needs. Let SMT Systems design, select and custom build your Rotary application to give you the reliable, efficient and feeding solution as per your requirement Different diameter range as per customer requirement. Rotary or vibratory option available Suitable for feeding application No damage to the parts Maintenance free design

Developing Machines

Get Price Quote

Rotary Torso Machine

Get Price Quote

We are the most well known Rotary Torso Machine manufacturer and supplier in India. Our Rotary Torso Machine is known for its optimum quality and strong built. It is corrosion resistant and built in a way that makes it stylish and sleek. It comes with unique designs with angled hip and thigh pads, thus eliminates lower body torque assuring proper isolation for torso area. This Rotary Torso Machine is offered with 9 position easy access adjustment handles, which allows the users to choose the motion. Features Easy handlingAbrasion resistantAdjustable9 position easy access adjustment handlesComfortable roller pads and angled grip handles Model : XL-1700 Unique design with angled hip and thigh pads eliminates lower body torque insuring proper isolation of torso area.9 position easy access adjustment handle allows users to choose the range of motion best suited to their individual needs.Comfortable roller pads and angled grip handles for proper ergonomics and comfort.

Rotary Bevel CNC Oxy Fuel Cutting Machines

Get Price Quote

The company is a well-known Manufacturer, Exporter and Supplier of Rotary Bevel CNC Oxy Fuel Cutting Machines in Pune. The Rotary Bevel CNC Oxy Fuel Cutting Machines can provide profile beveling along with shape cutting with the automatic height control offering accuracy in bevel tolerance. Available in several models, the Rotary Bevel CNC Oxy Fuel Cutting Machines are competitively priced and timely delivered. Features Simply supported gantry on two end carriages with dual synchronized A.C. servomotors providing motion along longitudinal axis (X-axis) and single A.C. servomotor providing motion along cross axis (Y-axis)Slave carriage driven either by rope and pulley mechanism or by stainless steel bandsGround ARCOR processed guide rails on all four sides Offered with latest AC Digital Servo machine for sharp acceleration, deceleration, zero backlash, dynamic braking and anti-skew Finely cut profiles with sharp edgesHigh quality gas cutting torches along with flash back arrestors and gas control solenoid valves for safety and repeatabilityPlasma torch protected from collision by magnetic brake away mountingBall screw driven slides ensure perfect up/down motion of torchesScope of supply includes rail and rail stand eliminating need of special civil work or heavy duty channelsLow cost of foundationEasy to operate Windows based CNC profile cutting controller Mirror image and auto plate alignment as well as total cut loss recovery Specifications Effective cutting width : 1.25 m to 6.5 mEffective cutting length : Depends on customer’s requirements. Modular 2 m and 3 m rail lengths.Positioning accuracy : ± 0.5 mm/ meterRepeatability : ± 0.2 mm/ meterPositioning speed : 6m to 12m/ minWork rest height : 700 mm to 750 mmWork rest : Standard cutting table, Fume extraction table, Water Bed, Underwater plasma cutting table

Rotary Swaging Machine

Get Price Quote

Shuz Tung Machinery was established in 1978 as a specialized pipe bender manufacturer of a wide variety of pipe benders and tube bending machines, such as auto pipe bender, semi auto pipe bender and special customer pipe benders. Dedicated to providing customers with the most credible and reliable industrial equipment, the company has been making relentless efforts on superior technology and engineering to enhance the performance of the pipe bender.

rotary transfer machine

Get Price Quote

For rotation-symmetric workpieces up to a maximum clamping diameter of 25 mm and up to a total length of 100 mm.Complete 3-sided machining with reclamping.

chicken rotary grill machine

Get Price Quote

chicken rotary grill machine, Eggs, Live Chicken, dressed chicken

Rotary Sand Sieving Machine

30,000 Per Piece

Rotary Numbering Machines

Get Price Quote

Rotary Numbering Machines, Origami Mailer, Leaflet Folding Machine