Wheel Capstan

We manufacture Wheel Capstans that are designed by experts to offer superior performance. The machine features a design that generates positive pulling force by length of contact. The Wheel Capstans are designed by a specialized team of experts after careful research to offer the best machinery for the cable industry. Salient Features : High friction surfaceEasy operationEasy maintenanceResistant to wear and tear Availability : Formats :VerticalHorizontalAngledSizes :600mm to 3600mm

...more

Triple Crosshead

Royle�s Triple Crossheads for MV and EHV applications contain many key features that have enabled them to be well proven in installations worldwide. All of the features are intended to promote product quality and integrity, to maximize the length of production runs, and to ensure operator �ease of use.� The internal flow distribution channels have been designed with the assistance of computer simulation models, but designs have been empirically enhanced as a result of actual process experiences. A key objective in the design of Royle�s family of triple crossheads is to minimize compound stress within the head. This has been achieved through careful balancing of the frictional flow paths of each polymer, strategic use of electric heaters in combination with oil circulation for heating and cooling for close temperature control, and complete separation of all three extruded layers until each is applied directly to the conductor or cable surface. Royle�s triple heads are well proven in service in manufacturing cables to the latest AEIC and IEC specifications. Benefits : Liquid Heat/ Cool CapabilityAdjustment of all LayersFull Separation of LayersWide Range of MaterialsDesigned to Allow Polymer RelaxationDesigned for Max Production RunsVCV / CCV / Triple Sioplas ApplicationsSupported by Royle Process Knowledge Full Separation of Layers: Due to the dissimilar rheological nature of the three polymers, Royle has carefully designed the flow distribution channels to maintain complete separation of each layer to the point where each is applied directly to the cable surface. This �full� separation of layers ensures smooth boundary interfaces free from protrusions and irregularities. Head Cleaning Station: The head cleaning station has a motorized turn table arrangement. This optional component facilitates easy dismantling and re-assembly of the complete crosshead.

...more

Single and Dual Layer Crosshead

Royle�s single and dual layer crossheads for Insulation and Sheathing applications contain many key features that have enabled them to be well proven in installations worldwide. All of the features are intended to promote product quality and integrity, to maximize the length of production runs, and to ensure operator �ease of use.� The internal flow distribution channels have been designed with the assistance of computer simulation models, but designs have been empirically enhanced as a result of actual process experiences. A key objective in the design of Royle�s family of crossheads is to minimize compound stress within the head. This has been achieved through careful balancing of the frictional flow paths of each polymer, strategic use of electric heaters in combination with oil circulation for heating and cooling for close temperature control, and complete separation of extruded layers until each is applied directly to the conductor or cable surface. Royle�s crossheads are well proven in service in manufacturing cables to the latest AEIC and IEC specifications. Benefits : Liquid Heat/ Cool Capability depending on applicationAdjustment of both Layers in dual layerWide Range of MaterialsDesigned to Allow Polymer RelaxationDesigned for Max Production RunsSupported by Royle Process Knowledge Attributes : Available with or without fluid cooling capabilitySturdy constructionCompact designDurableOperates smoothly even under high stress

...more

Royle Extruders

Our company is offering technically advanced and heavy- duty Royle Extruders that has earned high gratitude from the clients. First marketed in 1880, the product is regarded as one of the most preferable products. Due to its high durable performance our Royle Extruders have been successful in carving their distinct image in the industry. Without any quality compromise the product is offered at nominal rates that has attracted a huge clientele from the global as well as domestic market. Having high class testing facilities, the Royle Extruders are highly verified for ensuring their quality performance. Our engineers have enhanced the design of all components to meet the industry�s demands. The components are manufactured from computer-assisted design and extensive testing. Field testing applications Roller Feed SystemThermoplastic ProcessThermoset ProcessElectrically Heated Forced Air Cooled with CeraFin ExtruderElectrically Heated Liquid Cooled with AluFin ExtruderLiquid- Heated Liquid- Cooled with Spiroyle ExtruderGear Reduction SystemCylinder systemScrew systemHead systemTemperature systemProcess Control System Dimensions Screw diameter : 25mm to 200mmL/D ratio : 15:1 to 36:1

...more

pvc cable machines

Insulating and Sheathing Lines

5,000,000 Per 25000000 Set

Insulating and Sheathing lines are the primary products of Royle. Royle supplies complete system for Insulation of cables with line speeds as high as 1000 MPM, which varies for different conductor sizes. All equipment in the line is selected by Engineering Experts while considering optimum performance and least down time. The extruder sizes for the Insulating line vary from 25mm to 100mm. The system is used for basic products such as House Wiring Cables and even for Category Cables. The Sheathing lines are offered with line speeds up to 100 MPM for cable diameters up to 160mm. The Extruder sizes vary from 80mm to 200mm. The accessories such as Chalk Applicator, Semiconductor Skin Extruder, Graphite Applicator, etc. are chosen as per the product specifications. The basic System consists of Pay-offMetering CapstanMain Extruder and Auxiliary Extruders with accessoriesCooling TroughCapstanSpark tester and Diameter GaugeDancer/Float RollTake-upAuto-line Control System to integrate and control the line with most modern features

...more

House Wiring Cable

horizontal accumulator

We bring forth a comprehensive assortment of Horizontal Accumulator that is developed for wire storage during reel change on payoff or take-up. Use of a horizontal accumulator eliminates line speed reduction, gives continuous operation resulting in less man power and less scrap generation. Our range of Horizontal Accumulator is high on demand in the market and can be availed at the most competitive prices. Appreciated For : Continuous productionZero maintenanceCorrosion resistanceExcellent functionalityHigh durability

...more

dual take up machine

We are a prime Dual Take Up Machine Manufacturer, Exporter and Supplier from India, bringing forth this advanced machine for various requirements. Our Dual Take-up Machines are designed by experts to assist the automatic cross over process and in this, the manual loading and unloading of the bobbins takes place with the utmost efficiency. Features : Parallel shaft take up designRobust constructionMaximum efficiency even under high workloadEasy to maintainEasy to operatePLC controlled HMI operated

...more

Dual Flyer Payoff

Avail from us technologically advanced Dual Flyer Payoffs that are high on demand in the market. Our range of Dual Flyer Payoff is used for efficient reel handling for variety of applications. The pay-offs that we offer to the clients are available for different drum sizes and capacities. Besides, customers can also be eased with the availability of Payoff�s at the leading industrial prices. Popular For : Robust constructionCompact designTrouble free operationAbrasion resistanceSound insulationHigh line speeds

...more

Dry Cure CCV Line

Without any quality compromise the Dry Cure CCV Line is offered at nominal rates that have attracted a huge clientele from the global as well as domestic market. Owing to its high quality reliable performance our Dry Cure CCV Line has an individual image in the industry. Having high class testing facilities, the product is highly verified for ensuring a quality performance also our engineers have enhanced the design of all components to meet the industry�s demands. Our company�s improved and perfect method has resulted in the introduction of the Royle Drycure system. It works efficiently for non-voltage rated powers distribution cables and high-tension extra high voltage cables. Significant Features Space reducedSafety enhancedEarnings augmentedProductivity enlargedQuality enhancedEnergy consumption reduced Works Efficiently For High-tension extra high voltage cablesNon-voltage rated powers distribution cables

...more

Cooling System

One driven multipass cooling system with spray cooling to maximize cooling efficiency and minimize drag within the system. The system is 20� long and features low inertia sheaves and bearings for low wire tensions. The assembly contains precision machined aluminum sheaves with protective hard coating. Two sheave assemblies are mounted external to the wire bath enclosure by means of rigid steel bearing block fabrications to minimize vibration. All internal parts are corrosive resistant and enclosed within the fabricated stainless steel housing. The housing has a large water storage tank located directly under the wire bath section of the unit. Wire cooling is accomplished by individual spray nozzles mounted above and below the wire path between the end sheave packs. Four front doors are conveniently hinged out of the way for easy wire threading. Each door is sealed to ensure that water does not leak during operation and the doors are interlocked with the safety circuit to prevent line operation when open. Specifications: Sheave Diameter : 300mm � 500mmLength : 7.5 � 12.5Number of Sheaves : 6 - 10Cooling Medium : Spray or floodingEffective Cooling Length : 40 � 100M Acclaimed For : Continuous coolingError free operationLow maintenanceCustomized designEnvironmental adaptability

...more

Control Dancer

90,000 Per Set

1 Set(s) (MOQ)

We are recognized as a leading manufacturer, exporter and supplier of Control Dancer that is designed to control the speed of driven Pay-offs and Take-ups. Our array of Control Dancer is widely acclaimed by the clients as it eliminates back tensions. The Control Dancer that we offer finds application in various types of cables. Also, the range of Control Dancer offered by us complies with the international standards. Moreover, the control dancer manufactured by us is priced reasonably. Known For : Optimum efficiencyHigh flexibilityRugged constructionTrouble free performanceMinimal maintenance

...more

Continuous Vulcanizing Line

Due to its high durable performance our Continuous Vulcanizing Line has been fruitful in carving a distinct image in the industry. The product is offered at nominal rates that has attracted a huge clientele from the global as well as domestic market. Its insulation voltage ratings have a range from 600/1000 V to 69/72.5 KV with random runs of 138/145 KV also its cable jacket sizes run from ½ in 12.5mm to 4 in 100mm that is used sheathing for multiple conductor cables. The Continuous Vulcanizing Line is designed to manufacture various types of cables. Used for Manufacturing Cables with copper or aluminum conductors from #8AWG to 2000 MCM Cables weighing from 15 lbs per thousand feet (22 kg1000m) to 6200 lbs1000 feetGround aircraft power supply cablesVoltage rated power transmission cables Non- voltage rated power transmission cables Welding cablesMining machine Features Produces specific types of productsProduces according to customer�s product mixReliable and efficientDurable HCV Lines : ROYLE Horizontal Continuous Vulcanizing Systems have been supplied to the industry since the early 1930s for the manufacture of small and medium size automotive, signal, control, low voltage power transmission, building, appliance, service entrance, fixture, heater, thermostat and switchboard wires and cables as well as all types of portable cords. Each line is designed to produce specific types of products with components chosen according to each customer�s product mix. The types of wires and cables which the prospective machinery buyer plans to produce must be carefully specified to Royle so that our Sales Engineer can design a line and prepare a quotation for equipment suitable for those products. CCV Lines : ROYLE Catenary Continuous Vulcanizing Systems are designed for manufacturing all types of cables for the transmission of electric power including welding cables, mining machine and ground based aircraft power supply cables, voltage rated and non- voltage rated power transmission cables and sheathing for multi-conductor cables, where a vulcanized jacket is required. The catenary systems are used for cables with copper or aluminum conductors from #8AWG (10mm2) to 2000 MCM (1000mm2) and for cables weighing from 15 lbs per thousand feet (22 kg per thousand meters) to 6200 lbs per thousand feet (9200 kg per thousand meters). Insulation voltage ratings range from 600/1000 volts to 69/72.5 KV with occasional runs of 138/145 KV. Cable jacket sizes run from ½ in (12.5mm) to 4 in (100mm). VCV Lines: ROYLE Vertical Continuous Vulcanizing Systems are designed to process cables which are too heavy to be handled in a Catenary CV or are used when there is insufficient plant area or elevation difference to accommodate a Catenary CV System. Although a tower structure is always required for a VCV System, the total horizontal plant floor space is considerably less than that occupied by a CCV line. It is always preferable to design the VCV System without regard to existing towers to assure full production capabilities. However, the customer with a partially used tower already in their plant may insist on fitting the new machine into the existing facility, and Royle will then design the line in accordance with that requirement.

...more

Co-Axial Cable Extrusion

Royle Coaxial Cable Product Line freeFoam primary insulating for LAN plenum wires upto 60% foam. Primary lines are recommended for structured wiring, LAN, mini-coax, and RG series. For higher rate of foam, Nitrogen injection lines for Drop, Distribution, and Trunk CATV Nitrogen injection lines for RF, Mobile Communication and CATV Cables. System Parameters Application : RF, Mobile, Radiating, Trunk & Distribution CATVConductor Diameter : 2.0 - 6.0 mm Solid Cu, CCA, CCSCopper Tube Diameter : 4.0 - 10.0 mm Smooth Wall 12.0 - 19.0 mm CorrugatedCopper Tape Thickness : 0.25 - 0.7 mmFoam Diameter : 9.0 - 50.0 mmFoam % : Up to 80% Process Control : Advanced process control with computer autoLine control system. Ability to measure, capture, and control many process variables to achieve a high level of process stability. Variables include melt pressures, diameters, capacitance, nitrogen injection pressure, trough temperature, etc. All data is captured in a data base file in real time and can be manipulated in real time or historical time. System features SPC/SQC and full trendingpackage. Features : Air cooled (7) zone 80mm 38:1 L/D foam extruder with unique stock screw technologySophisticated nitrogen injection system with multiple portsAdvance auto line control systemLine components designed specifically for manufacturing hing frequency cables

...more

Caterpillar Capstan

We bring forth an extensive range of Caterpillar Capstans for varied applications. Developed using cutting-edge technology, our Caterpillar Capstan is made available in various specifications with grip length ranging from 600mm to 2100mm. manufactured using premium materials, our Caterpillar Capstans form an indispensable part of many high-tech cable manufacturing systems all over the world. Construction and Working : Caterpillar Capstan provides product contact pressure using number of independent tension rollers. Driven by a quiet gear box, the arrangement comprises upper and lower mechanical drive component belts. The reversible model consists of the motor attached with gearbox through silent timing belt and pulleys. The reversible facility allows the main body of capstan to be removed from stand and flipped to be run in opposite direction. Attributes : Unique designSuperior performanceCompact structureEasy operation and maintenanceDurable Perfect For : MeteringPulloutHelper applications

...more

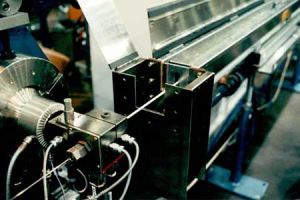

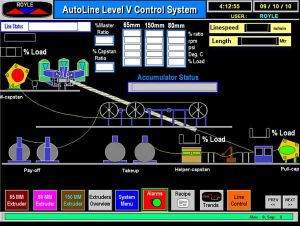

Autoline Control System

Royle�s autoLine control system is the complete solution for line control and process analysis.Close control of all operating parameters is assured through the use of the proven autoLine control system that operates in a Windows NT environment, incorporates precision drives, temperature controls, PLC, graphical user interface, and integration of all quality & measuring devices. The system also features scaleable system architecture for faster and simpler upgrades and an integral high speed modem located in the control panel enables telephone connection to Royle for software updates, remote troubleshooting, or routine maintenance Real-time & historical trending for SPC/SQC is available. Royle AutoLine is a sophisticated, easy-to-use, and powerful automated solution to your manufacturing needs. The fully integrated package is designed for both standalone and networked plant-wide applications and dramatically improves productivity, maximizes product quality and minimizes operating costs & time. Royle autoLine is a proven design with an installed base worldwide. Intuitive human-machine-interface (HMI): AutoLine�s human-machine-interface (HMI) integrates the whole process into an intuitive �window� into the process. The HMI provides the operator with a powerful tool that is easy to learn and use and features dynamic color graphics. Data Acquisition/Analysis: AutoLine�s real-time and historical trending is a monitoring and data collection tool that continually improves the process, maximizes product quality, and minimizes product waste. A database manager constantly captures the operating parameters enabling manipulation of data. Recipe Generator: The autoLine recipe feature allows the operator to instantly upload/download stored product parameters, machine setpoints, and other variables to and from the process which significantly reduces set-up times and ensure process repeatability.

...more

Cable Machine

Extrusion lines for manufacturing building wires, low voltage, medium voltage, high voltage and extra high voltage power cables such as insulating lines, sheathing lines, jacketing lines, ccv lines, triple extrusion lines, high temperature cable insulating lines, rubber cable lines, coaxial cable manufacturing lines etc.

...more

coaxial cable machine

thin cable machine

Be first to Rate

Rate ThisOpening Hours