Wet Scrubbers

effective removal of particles from your industrial air SAKA make Wet scrubbers are based on the venturi scrubber principle, with process capacity up to 2.5 Mg per mt. cube. Known for there effectiveness in challenging and diverse processes, We offer Wet as well as twin scrubbing systems. Practically washing the dust and particles out of the air our scrubbers forces exhaust air into a spray chamber where fine water particles cause the dust to drop from the air stream leaving the clean air as an output. Our scrubbers are reaction free and has add-on energy facility. Option of water cooling system can also be supplied in case of specific requirement.

...more

Vibratory Fluid Bed Dryer

Controlled drying with continuous processing Vibratory Fluid Bed Dryer are used for mass heat transfer and have relative smaller residence time. SAKA’s Vibratory Fluid Bed Dryers are known for its versatile applicability with a ability to process wet as well as semi wet products. Vibratory motion in this type FBD’s moves the product through Dryer. Usually a push-pull system is used to balance the pressure to slightly negative in the free board of the fluid bed. Depending upon the product and available heat source, direct or indirect heating may be applied. Then the exhaust air is cleaned by bag filter, cyclone with or without wet scrubber. SAKA’s Vibratory Fluid Bed Dryer are known for maintaining equilibrium of thermal efficiency and moisture content of the material thus ensuring effective, efficient and controlled drying.

...more

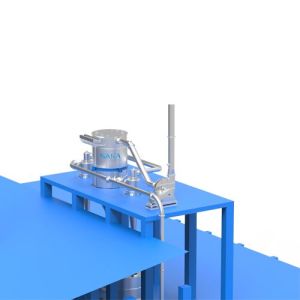

vibratory dryer

Vibratory Fluid Bed Dryer are used for mass heat transfer and have relative smaller residence time. SAKA’s Vibratory Fluid Bed Dryers are known for its versatile applicability with a ability to process wet as well as semi wet products. Vibratory motion in this type FBD’s moves the product through Dryer. Usually a push-pull system is used to balance the pressure to slightly negative in the free board of the fluid bed. Depending upon the product and available heat source, direct or indirect heating may be applied. Then the exhaust air is cleaned by bag filter, cyclone with or without wet scrubber. SAKA’s Vibratory Fluid Bed Dryer are known for maintaining equilibrium of thermal efficiency and moisture content of the material thus ensuring effective, efficient and controlled drying.

...more

Tube Bundle Dryer

Controlled drying, performed efficiently Tube Bundle Dryers provide effective and efficient drying for materials which require lower drying temperatures. Main element of these type of Dryers are steam heated tube, it dries the product by rotating inside a firm housing. SAKA�s Tube Bundle Dryers are highly efficient and require less warm air to dry the product thus there is less emission of air. In Tube Bundle Dryers, feed comes in contact of heated tube and not directly heating medium. This makes is perfectly applicable for products which are free flowing and non sticky. Typically these Dryers are indirect type Dryer with counter current flow principle i.e. warm air flow in opposite direction of the feed.

...more

Spray Dryers

The Spray dryers are designed based on inputs derived from in-depth analysis of your process parameters, available space and the application. Engineering and automation in SAKA�s Spray Dryers provide you with complete control on configuring key process characteristics such as moisture content, particle size, bulk density, flow patterns etc. to manufacture the desired product.

...more

SPRAY DRYER WITH ROTARY ATOMIZER

Instant drying with high speed dispersion Spray dryers with Rotary Disc Atomizers from SAKA are capable to handle material in large quantities and any viscosity. Wheel design is customized according to powder characteristics. Ideal for applications like herbal extracts, ceramics, inorganic chemicals and dye stuffs , these Spray Dryers are used where liquid feed is required to converted into fine droplets. Feed is introduced through a high speed rotating disc which throws liquid outward at very high velocity. This leads formation of fine droplets which are dispersed on the walls of the spray dryer. these droplets when comes in the of hot airgas to form dry solids, granulate or agglomerate particles

...more

SPRAY DRYER WITH NOZZLE OPERATION

Uniform particle formation with effective drying In case of Spray Dryer with Nozzle, Dryer comes with a spray nozzle which facilitates formation of fine droplets at very high speed. These kind of Dryers are used where faster evaporation of heat is required. Here feed is introduced in drying chamber through a high pressure nozzles forming small droplets. These fine droplets get dried immediately as soon as they come in contact of hot air.

...more

Spray Cooler

Spray Cooler or Congealers are ideal solution for processing organic chemical, food and heat sensitive material. SAKA spray coolers are highly regarded for their efficient and effective processing. Manufactured with latest technology and exquisite quality raw materials our Coolers are extremely easy to operate and maintain. Known for it’s capability to process very fine particles Spray Coolers from SAKA can process coarse particle products with mean particle size of 50-150 micron. In case specialised requirement a second stage of processing can also be provided with FBD or pneumatic conveying system. Environmental norms are one of important factor when it comes to spray cooling, SAKA’s expert team ensures that our coolers stay well within these norms.

...more

Spray Cooler

Spray Cooler or Congealers are ideal solution for processing organic chemical, food and heat sensitive material. SAKA spray coolers are highly regarded for their efficient and effective processing. Manufactured with latest technology and exquisite quality raw materials our Coolers are extremely easy to operate and maintain. Known for it�s capability to process very fine particles Spray Coolers from SAKA can process coarse particle products with mean particle size of 50-150 micron. In case specialised requirement a second stage of processing can also be provided with FBD or pneumatic conveying system. Environmental norms are one of important factor when it comes to spray cooling, SAKA�s expert team ensures that our coolers stay well within these norms.

...more

Spin Flash Dryer

Consistent drying with economical drying process Widely used for generation of dry powder, SAKA’s Spin Flash Dryers are known for consistent performance, sturdy design and lower operating costs. Ideal for continuous operations these type of Flash Dryers are extremely fuel efficient and low at energy consumption. In Spin Flash Dryers, viscous, paste or cake type of feed is introduced to dis-integrator which breaks the lumpy material. The disintegrated material is brought in contact of warm air which drys it almost instantly. Spin Flash Dryers are ideal for products such as fertilizers, pigment, dyestuff etc. SAKA’s Spin Flash Dryers are compact in design and Requires lesser space. These dryers meets all the pollution control norms and ensures clean environment.

...more

Rotary Disc Atomizers

Ensuring perfect particle formation Rotary disc atomizers are ideal for material which are viscous or very abrasive in nature. These atomizers come with a perforated disc which rotates at very high speed, large flow rates and provide homogeneous spray. The feed is introduced through this rotating disc which throws the liquid outward, at very high velocities to create formation of fine droplets. In-depth analysis of Rotary Disc Atomizer designs using advanced CFD analysis means an assured performance and long life when put to use. RANGE: A60 A100A150A250A300A350

...more

Rotary Cooler

long lasting and consistent performance Rotary coolers from SAKA are known for their long lasting and consistent performance. SAKA has built a strong capability to design and develop customised Rotary Coolers as per specific requirement. Whether you require short or long residence times, chilled or ambient cooling air, carbon steel or specialty steels, we can design a Rotary Cooler for your application and analyze its performance well before manufacturing. Rotary Coolers have heavy-duty drum construction. This makes it ideal for wide range of applications and large capacity processing for both drying and cooling procedures. Typically, Rotary Coolers work on the principle of counter current air flow where chilled or ambient air comes first in contact with material at its highest temperature leading to efficiently cooling. Additionally, flights lift and cascade material through the drum, enhance the cooling process.

...more

Pneumatic Conveyor

Bulk material movement made easy Pneumatic conveyors use air as a force to transfer the material. The quantum of force to be applied depends on the product and its properties. Since hot or cold air can be used in the pneumatic conveyors, additional drying or cooling effect can be provided. SAKA’s pneumatic conveyors can be used with spray dryers and best result can be achieved if ambient air is used giving dual effect of conveying as well as cooling the material.

...more

MIXED FLOW SPRAY DRYER

Superior performance with better mixing process This is a combination type of air flow system i.e. Counter as well as Co-current. Here Air is introduced from the top and atomizer is located at the bottom, thus providing mixed flow effect. This type of drying is slightly identical to counter current hence it is not applicable for heat sensitive material.

...more

FIRED CALCINER

efficient drying for low temperature processing In Indirectly Fired Calciner, material is heated with the help of the burners which are on the outer periphery of the dryer. Here, the heat is transferred by way of radiation and conduction through the cylinder wall. The rotary drum is partially enclosed and externally heated by a series of burners mounted in an insulated stationary chamber or jacket. Ideal for materials which require medium or low temperature, Indirectly Fired Calciners are used for drying dusty, fine or heat sensitive materials.

...more

Heat Exchangers

Transferring high efficiency heat SAKA offers complete range of heat exchangers, used for providing warm air to Dryers, Evaporators, Ovens many other applications. Known for high thermal efficiency, proper insulation our heat exchangers comes with direct and indirect type. Using steam, oil and electricity as fuel SAKA make heat exchanger are capable to provide consistent heat through out the process. Unique expansion arrangement or longer life Integrated fin design for highest efficiency Corrosion resistant construction Low pressure dro

...more

Gas Fired Hot Air Generator

SAKA has a full range of Hot Air Generators or Air Heaters. Our Hot Air Generators (HAG) comes with robust and sturdy design to provide you required heat consistently and in safe manner. Known for its compact design and fail proof arrangement SAKA make HAG are ideal for wide range of industries right from Chemical to fertilizer to Food. SAKA’s fully automatic HAG are extremely easy to operate with just push of button and does not require specially trained resource. Known for its economical efficiency our HAG can provide clean and safe hot air making it ideal choice for food and pharmaceutical industry.

...more

FLUID BED COOLER

Fluid Bed Cooler from SAKA offers a series of advantages such as homogeneous mixing, lower fluidising velocity, lesser energy consumption etc. Fluid Bed Cooler uses ambient or cool airgas to dry the feed. These type of coolers are ideal for removal of the last trace of moisture from the feed. Fluid Bed Cooler is a modular type of cooling solution, Similar to Fluid Bed Dryer, Coolers also keep material in Fluidization state with the help of air or gas. This leads to the entire surface area of the material to get exposed while it is suspended , increasing cooling efficiency. Use of Cool air means drying without any degradation of the product, this making it ideal for heat sensitive materials. Fluid Bed Coolers can work effectively in continuous as well as batch type processing. Using Fluid Bed Cooler in close loop helps to increase solvent or gas recovery.

...more

Flash Dryer

Flash Dryers are one of most economical options in drying technology which requires minimum labor and lowest maintenance costs. SAKA’s Flash Dryers are user friendly and extremely to easy to maintain. Here feed has very low residence time and drys almost instantly. Material drys as it is conveyed. These Dryers are known for their superior product quality and reduces the risk of over heating. Flash Dryers are widely used in industries such as Agro-chemicals, food, minerals, dyestuff etc

...more

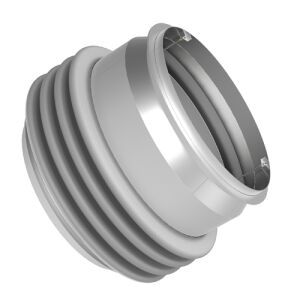

EXPANSION DUCT

Expansion ducts, also known as expansion bellows or joints, are used at the ducts which are prone to get damaged due to thermal growth, vibration, pressure thrust and other mechanical forces. SAKA’s flexible steel make expansion ducts are tested for performance using extensive CFD analysis thereby assuring good quality and zero wastage of material or heat due to leakage. Sturdy construction means the bellows can withstand the pressure, thermal growth as well as vibration during process ensuring the safety of material and operators. Available in large sizes (350mm to 2 m) Engineering assistance for designing and installation of expansion duct

...more

DIRECTLY FIRED CALCINER

Effective drying for high temperature processin Directly Fired Calciners are used for high temperature application. The process usually has longer resistance time, The length of diameter ration is often in excess of 10:1 to control the temperature along the length of the Calciner. Burner fires directly from the discharge end of the dryer. The drying is achieved in three ways – by radiation from the burner flame, conduction from the refractory lining and convection by contact with the hot gases.

...more

Cyclone Separator

Economical and efficient removal of large particulate Cyclone separators or simply cyclones are separation devices that use the principle of inertial to remove particulate matter from flue gases. SAKA has been leading the way in single and multi Clone separator s capable of handling very large scale projects, for various specialist applications. Our Cyclone separators are reaction free and are capable to handle very high temperature. Tested by advanced CFD analysis technique SAKA’s Cyclones can process highly corrosive material.

...more

COUNTER CURRENT SPRAY DRYER

In these type of Dryers, air and feed are introduced from opposite directions. Feed is introduced from the top and hot air is introduced from the bottom.Counter Current Dryers have better efficiency and output, but are not ideal for heat sensitive material. Typically, these type of Dryers are ideal for products like Soaps, Dyestuff, Detergents etc. Here feed first comes in contact of warm at its lowest temperature and gradually gets exposed to the hotter air. Counter Current Dryers are more effective and have better thermal efficiency then that of a Co-current Spray Dryer.

...more

COUNTER CURRENT ROTARY DRYER

Counter current type of rotary dryer is an ideal solution for materials that must be dried to contain very low level of moisture. Here warm air is introduced at the discharge point of the Dryer. The material comes in contact with the warm air first at its lowest temperature, which goes on increasing as the material travels further. The material which is at its final stage comes in contact of airgas at its highest temperature thus maintaining very low level of moisture content.

...more

Advanced CFD Analysis services

Site Fabrication Services

Installation services

Be first to Rate

Rate This