Universal Sliding Support Rings

Designed for the Easyshrink™ 15 device, the universal sliding supports can be equipped with interchangeable support rings to carry any kind of Shrinkfit holder.

...more

Universal Drill Chucks

Seco universal drill chucks provide a simple, easy to use solution for holding drills. The compact design is compatible with clockwise and counterclockwise spindle rotation and allows the tool to be changed directly on the machine.

...more

Tool Supporting Sleeves

Available for Easyshrink 20 #3, tool supporting sleeves for stop rods locate the cutter onto the stop rod, freeing both hands when using direct tool-height measuring.

...more

TOOL BOY - ASSEMBLY SUPPORT

Easy to mount on a tool cart, Tool Boy allows tool assemblies to be rotated 360 degrees to easily access all features. Assemblies can be rotated on the horizontal plane and secured in the horizontal position, allowing tools to be tightened with substantially less force. This ergonomic and user-friendly design allows for quick assembling and disassembling of cutting tools on toolholders.

...more

Test-Control Bars

Seco test bars are primarily used for checking accuracy and to set the axes of the machine tool and tool presetter.

...more

tapping chucks

Seco’s range of tapping chucks offers machined thread results on machines with and without synchronized spindle rotation vs X & Y table axis.

...more

Stop Rods

The stop rod adjusting system allows the shrinking depth of the tool to be set to avoid the use of stop end screws that could generate constraints on the tool shank after the cooling of the Shrinkfit holder.

...more

Stop End Screw Setting Adapters

Seco stop screw setting adapters type 05R5600 are used in conjunction with the comparator of the Pack Easyshrink™ 20 N°3. They allow accurate positioning of the stop end screw of Shrinkfit holders.

...more

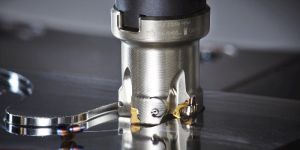

SQUARE SHOULDER MILLS

These multipurpose 90° square-shoulder milling cutters are for heavy roughing applications, delivering large depth-of-cut capability and high feed rates for consistent performance and excellent metal-removal rates. Cutter range 63-315 mm (2-6 inch) Max depth of cut 24 mm (0.94 inch) Recommended slotting depth of cut 13 mm (0.51 inch) Insert corner radii range 1.6 mm (0.063 inch)

...more

SQUARE SHOULDER MILLS FOR ADVANCED CUTTING MATERIALS

Seco offers a variety of square shoulder milling cutters for use with advanced cutting materials, allowing you to take advantage of these cutters’ benefits, such as higher cutting speeds. When applied correctly to appropriate applications, PCBN, PCD and ceramics provide unbeatable boosts for square shoulder milling productivity.

...more

SQUARE SHOULDER MILL

We have one of the most comprehensive and versatile selections of advanced square shoulder milling cutters on the market today. So, no matter the workpiece material, depth of cut or tolerance requirement, we have a solution that can optimize your operations, boost your profitability and keep you competitive.

...more

Solid Carbide Drills

Incorporating a wide range of geometries, coating and diameters, Seco’s diverse portfolio of solid drills excels across a broad spectrum of workpiece materials, from steel to stacked composites and difficult-to-machine materials. With diameters as small as 0.1 mm (.003 inch), our range covers a comprehensive array of applications for varied industry segments, including medical and aerospace. Optimized geometries provide options for challenging applications, including irregular exit shapes. With these tools you can use high feeds and cutting speeds and achieve close hole tolerances with geometries suitable for all workpiece materials. Diameter range 0.1 – 20 mm (.003 – .787 inch) with hole tolerances from IT7 to IT12.

...more

Solid Carbide Cutter

Our wide, innovative and powerful range of solid end mills and milling cutters and inserts is well known in the industry. We offer a wide selection of milling solutions to handle all workpiece materials – from soft steel to easy-to-machine aluminum to difficult-to-machine superalloys. Regardless of your milling operations, you’ll find what you need. Plus, we offer the support you need to make sure you select the right tool to improve productivity and product quality

...more

Slotting Cutters

Economical and free-cutting disc milling Width of cut 11-21 mm (.39 - .83 inch) Cutter range diameter 25-50 mm (.97 – 1.84 inch) 4 cutting edges Internal coolant

...more

SINGLE-SIDED INSERTS

TURBO - 2-CUTTING-EDGE, SINGLE-SIDED INSERTS The Turbo family takes square shoulder milling to the max. Suitable for most roughing, semi-finishing and finishing operations, these highly versatile cutters offer long tool life and high precision via optimized properties that reduce heat generation and cutting forces. The tools feature a coated, pre-hardened cutter body with two different pitch configurations for meeting tight tolerances and providing high reliability in a broad range of workpiece materials. Not only does this coated/hardened surface protect the tool from wear, it also prevents chips from welding on the cutter body. Turbo cutters have precision milled pocket seats that improve run-out, stability and tool life by providing optimal contact between the tool body and insert. Integrated through-coolant channels support high productivity and promote excellent chip evacuation.The comprehensive range of inserts, carbide grades and corner radii available for use with Turbo cutters further increase their adaptability, accuracy and reliability. Inserts can be set to a true 90-degree cutting angle to create clean 90-degree walls and eliminate secondary operations. Inserts lock into place via a strong center screw placed in the same direction as cutting forces, and wiper flats optimize surface finishes. Such versatility also makes it possible for Turbo cutters to excel in slotting, ramping, facing, pocketing, plunging and turn milling operations. Mounting types for the Turbo family include Cylindrical, Weldon, Arbor and Combimaster™.

...more

side lock holders

Seco’s range of side lock holders uses side locking screws to secure the tool shank against the bore of the toolholder and offer anti-pull-out protection. This makes the holders very well suited for heavy machining operations.

...more

Shrinkfit Holders

Seco shrinkfit holders are the slimmest possible way to hold round tool shanks with high precision and strong clamping forces, all without additional clamping screws or nuts.

...more

SHRINKFIT DEVICES

Our range of Shinkfit devices can meet the needs of any manufacturer, offering fast performance and incredibly reliable precision. These systems incorporate automatic heating cycles and efficient cooling cycles that use forced air or water cooling bells. Additionally, the use of stop rods for height setting further ensures stability, reliability and accuracy.

...more

shell mill holders

Seco offers a broad range of shell mill holders based on spigot and tenon drive features according to ISO 3937. Providing excellent results in rough to fine milling applications, this portfolio includes options for most machine side connections, as well as most workpiece side diameters.

...more

Shell Mill Holder

Seco shell mill holders are designed to hold milling cutters in rough to fine milling applications. There are two conventional shell mill holder types for spigot and tenon drive: small face type according to ISO 3937 and large face type according to the latest milling cutters’ face diameters.

...more

Seco-Capto Modular System

The Seco-Capto™ modular tooling range uses Polygonal Shank Coupling (PSC) in accordance with ISO 26623 and features a self-locking taper joint.

...more

Rotary Coolant Inducers

For machines not equipped with through-the-spindle coolant, rotary coolant inducers for drills provide a means of delivering coolant through the drill. These inducers are available with Graflex back-ends in size 5 or 6 and in five types of front-ends. Front-end options include: Type BSM/6181-6183 for Type 7 drill shanks, ISO 9766 (Weldon compatible); Type BSM/6100-6101 for Perfomax drills with Type 7 shanks, adjustable +0.8 to -0.3 mm on diameter; and Type BSM/401: for Graflex modular system modules. Inducers are available for manual and automatic tool changers.

...more

REAMING

Our broad selection of high quality, easy-to-use reamers are perfect for advanced machining and large batch production. These holemaking products range from 3 – 154.5 mm in diameter and feature optimized cutting grades and geometries for achieving high productivity in all workpiece materials.

...more

Power Milling Chucks

These chucks are specially designed for challenging rough-milling applications, supplying high metal-removal rates due to heavy machining capabilities.

...moreBe first to Rate

Rate ThisOpening Hours