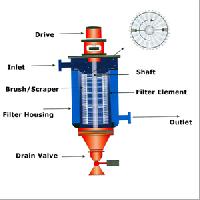

self cleaning water filter

200,000 Per Set

Self cleaning (auto backwash) filters combine the advantages of high quality filtration from different water Sources (Sewage, Reservoirs, River, etc.) with self cleaning features, where the flow is uninterrupted during the filtration process. The filters are designed for use in a wide range of industrial, municipal and irrigation applications.The main element is made of stainless steel with a large filtration open area for water flow in order to Withstand high dirt load and pressure. Cleaning of the screen is performed once the pressure loss across the filter has reached the present value (up to 0.5 kg/cm2) The filter is equipped with a coarse screen that protects the finer screen from stones and larger particles. The flushing valve opens and pressure is released from the hydraulic piston, then water flows outside through the flushing valve. Pressure in the hydraulic motor chamber and the dirt collector is significantly lowered. The dirt collector nozzles movement and rotation cleans the screen's entire internal surface. The flushing cycle takes 10 seconds. The flushing valve closes at the end of the cycle and the filter is clean. During the cleaning cycle, the filtration process Remains uninterrupted. Hence you will get filtered water continuously.

Self Cleaning Filters

Get Price Quote

Self Cleanings Filter has developed a self-cleaning filter, designed to handle large flows, higher pressures & heavy dirt loads. It cleans itself automatically either by sensing pressure drop across the filter, or by timer, whichever occurs earlier. Filtration up to 80 micron. No Consumables. Totally automatic operation using differential pressure.

Best Deals from Self Cleaning Filters

Automatic Self Cleaning Filter

70,000 Per Piece

Self Cleaning Filter

Get Price Quote

Dirt collected is ejected out automatically with little fluid. Shell of the filter is fabricated in MS & is designed to handle working pressure of filter. Filter elements are SS304 wedge-wire screen candles, mounted vertically with their bottom ends open to dirty fluid & top ends closed. All candles are exposed to flow of dirty fluid, except one. Dirt is collected inside the candles. One of the candle's outlet is opened to backwash port by aligning rotary face seal to it. Backwash outlet valve is opened for a short time so that the dirt collected in this candle is let out to atmospheric pressure. Since large pressure differential is available between working pressure of filter & atmosphere, backwashing is very effective. When the preset pressure drop reaches (or time elapsed is complete), the rotary face seal is aligned with next candle outlet & backwash outlet valve is opened for a short time to effect backwashing of that candle. The process is repeated automatically to keep the filter clean & to eject the dirt. A recovery filter is provided to recover fluid ejected along with the dirt. Wedge-wire screen openings, number of working candles, candle sizes can be altered depending on following: Flow & viscosity of fluid, quantity & type of dirt etc. The filter housing can be designed to handle required working pressure. Filter presently developed has 8 candles, 1000 mm long X 100 mm diameter. It is designed for flow of 8000 LPM (480 m3/hr) of water based emulsion for filtration level of 100 microns. It is going to work as Roll Coolant Filter for a steel cold rolling mill.

Self Cleaning Filters

Get Price Quote

Self Cleaning filter holds multiple elements ( based on flow capacity ) housed in a pressure vessel. The dirty fluid enters from the bottom into the inner side of these elements. The dirt starts accumulating on the inner surface. This accumulated dirt increases the differential pressure, which is sensed by a pressure switch. On reaching a set differential pressure an dedicated panel start the backwash cycle. A rotating arm, placed under the elements, connects the element opening to atmospheric pressure. As the complete housing is operating at a higher pressure, the fluid starts a reverse flow from outside to inside for that particular housing. This flow dislodges the accumulated dirt on the inner surface and that particular element is backwashed. After a set time delay the backwash arm rotates to the next element. This countinues until all elements are backwashed. Various elements of filtration level upto 150 micron are available. Number of elements in the housing are decided on the process, flow and dirt load. Features : • Completely automatic • Robust design Application : • Roll coolant filtration system • Cooling tower water filtration • Water filtration system for Boiler feed • Food processing etc.

Self Cleaning Filters

Get Price Quote

Avail from Us a Huge Range of Self Cleaning Filters that is Manufactured from the Premium Quality Raw Materials. Our Self-cleaning Water Filters are Available in Various Sizes and Dimensions and Can Be Customized as per the Requirements of the Clients. Our Softening and Dm Plants are Easy to Install and Need Low Maintenance. We are Well Reckoned as One of the Major Auto Self Cleaning Filters Manufacturers, Based in India.

Self Cleaning Filter

Get Price Quote

Cabinet Type Front Loading Cleaning Machine, roll coolant filtration system

Self Cleaning Filter

Get Price Quote

upflow filter, Multistage Pump

Self Cleaning Filter

Get Price Quote

upflow filter

Wall Mounted Self Cleaning Cartridge Filter

Get Price Quote

Wall Mounted Self Cleaning Cartridge Filter

Self Cleaning Filter

Get Price Quote

Raotary Table Bin / Tray Cleaning Machine

Self Cleaning Wedge Wire Drum Filter

Get Price Quote

Self Cleaning Wedge Wire Drum Filter, Centralized Cooling Units