weighing transmitter

125,000 Per Piece

1 Piece (MOQ)

Vibro Sifter Machine

145,000 Per Piece

1 Piece (MOQ)

Voltage : 380-415 V AC

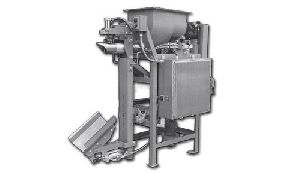

valve bagging machine

195,000 - 285,000 Per Set

100 piece (MOQ)

SHREE GURU ENTERPRISES INDIA is an international leader in valve bag fillers. Its wide range of valve bag fillers covers several industries, primarily chemicals, minerals and foods. The acquisition of the bagging equipment division at Graphic Packaging International Inc. in 2009 gave SHREE GURU ENTERPRISES INDIA more than 10 years of experience in the manufacturing of innovative valve bag fillers. This unique expertise makes SHREE GURU ENTERPRISES INDIA the supplier of choice for your needs in vacuum valve bag fillers, air packers, auger valve bag fillers and impeller valve bag fillers. Several types of auxiliary equipment are also available, including low- and high-end valve bag applicators/placers, robotic bag handling systems for valve bags, and ultrasonic sealers and bag closers, primarily for the food, chemical and mineral industries.Pneumatic Valve Bag Packing Machine is s designed to is designed to fill free flowing,non clumping dry powder or granulates into valve bag25kg Cement Pneumatic Valve Bag Packing Machineis suitable for Powders,Sands, Cement, Tile adhesives, Plastics, Renders and Granulated Rubber.Features:• Excellent performance• Long lasting performance• High efficiencyApplications:• Ideal for Packing of: Wall Putty Powder, Construction Chemical, Lime Powder, Dry Mortar etc...Specifications:• System: Valve Type Bag Filling Machine• Capacity: Max 50 kg, 20 kg• Output: 6-8 bags per hour powder• / granule• Dimension: L-1500 mm X w- 1500 mm X H 2900 mm approx• Accuracy: +/-0.2%• Number of Filling: 1-2 Bags / min for granule, 1-2 bag / min Powder• Filling Valve: Screw Motorized & Pneumatically operated Gate• Features of the control Panel: coarse & fine set, weight set, bag count, LED Display, Start Stop control• Weight Sensor: Load Cell• Dimension: L-1400 mm x W-1050 mm x H 1200 mm• Power: 230v AC, 50Hz• Air Supply: 5-6 kg Cm2

Country of Origin : India

Type : Valve Bag Packaging Machine, Valve Bagging Machine

Application : Bag Packaging

Weight : 100-1000kg, 4000-5000kg

Color : Brown, Grey

Voltage : 110V, 220V, 380V

Condition : New

Automatic Grade : Automatic, Fully Automatic, Manual, Semi Automatic

Power : 1-3kw, 380V

Warranty : 1year

Driven : Electric, Mechanical

...more

Valve Bag Filling Machine India

155,000 - 265,000 Per Sets

100 Set (MOQ)

shree guru enterprises india is an international leader in valve bag fillers. its wide range of valve bag fillers covers several industries, primarily chemicals, minerals and foods. the acquisition of the bagging equipment division at graphic packaging international inc. in 2009 gave shree guru enterprises india more than 10 years of experience in the manufacturing of innovative valve bag fillers. this unique expertise makes shree guru enterprises india the supplier of choice for your needs in vacuum valve bag fillers, air packers, auger valve bag fillers and impeller valve bag fillers. several types of auxiliary equipment are also available, including low- and high-end valve bag applicators/placers, robotic bag handling systems for valve bags, and ultrasonic sealers and bag closers, primarily for the food, chemical and mineral industries.pneumatic valve bag packing machine is s designed to is designed to fill free flowing,non clumping dry powder or granulates into valve bag25kg cement pneumatic valve bag packing machineis suitable for powders,sands, cement, tile adhesives, plastics, renders and granulated rubber.features:• excellent performance• long lasting performance• high efficiencyapplications:• ideal for packing of: wall putty powder, construction chemical, lime powder, dry mortar etc...specifications:• system: valve type bag filling machine• capacity: max 50 kg, 20 kg• output: 6-8 bags per hour powder• / granule• dimension: l-1500 mm x w- 1500 mm x h 2900 mm approx• accuracy: +/-0.2%• number of filling: 1-2 bags / min for granule, 1-2 bag / min powder• filling valve: screw motorized & pneumatically operated gate• features of the control panel: coarse & fine set, weight set, bag count, led display, start stop control• weight sensor: load cell• dimension: l-1400 mm x w-1050 mm x h 1200 mm• power: 230v ac, 50hz• air supply: 5-6 kg cm2

Country of Origin : India

Type : Valve Bags

Thickness : 10-20microns, 40-50microns

Application : Chemical Pacakging

Color : Black, Brownish, Green, Grey, Red

Feature : Barrier, Moisture Proof

Pattern : Plain

Capacity : 1kg, 25kg, 50kg

Brand Name : SHREE GURU

Industrial Use : Yes

...more

valve bag filling machine

195,000 Per Piece

1 Piece (MOQ)

Power : 2hp

Power : 230v AC, 50Hz

vacuum transfer system

200,000 Per

1 Piece (MOQ)

Brand Name : Shree Guru

Power : 1 Hp

Voltage : 220

...more

Vacuum Pressure Impregnation Plant for Motor

125,000 Per

1 Piece (MOQ)

Voltage : 380 - 415V AC 50Hz

Vacuum Pressure Impregnation Plant for High Voltage Motor

125,000 Per Piece

1 Piece (MOQ)

Warranty : 12 Months

Vacuum Pressure Impregnation Plant

105,000 Per Piece

1 Piece (MOQ)

Voltage : 380V AC 415V AC

Vacuum Conveying System

125,000 Per Piece

1 Piece (MOQ)

A basic vacuum conveying system uses a metering device at the inlet, a pipeline, receiver and exhauster. We facilitate our clients with a quality spectrum of Vacuum Conveying Systems that is much cherished in the market. The provided systems are manufactured with the use of top-notch quality components with the aid advanced techniques in adherence with set industry standards. The offered systems find their usefulness in different food processing, chemical, and mining, construction and related industries. Moreover, these systems can be easily purchased at reasonable prices from us. These advantages include : Energy savings High reliability Routing flexibility Low maintenance cost Better process control Improved safety Lower operating cost Ability to handle toxic materials Better long distance handling The two most distinct Categories of vacuum Conveying Systems can be described as Following : Material can be customized by stainless steel SUS304 or SUS316 to meet GMP standard; It’s completely sealed for dust-free working condition This vacuum conveyor can feed powder or small granule product into sealed or open containers; The machine boy is compact,reliable and operation is very easy Features Applications : The receiver needs to be sealed and vacuum tight to enable the system to operate effectively Another possible benefit results from the system being under negative pressure; potential leakage of toxic or hazardous products is prevented. The conveying rate for a vacuum system is limited by the negative pressure that can be created by different exhausters. We would typically not design a vacuum system to operate in excess of -400mbarg. Vacuum systems are generally better suited to lower throughputs and conveying distances when compared with pressure conveying system. Frequently used in ‘hopper loading’ applications often known as ‘suck and dump’ Air and products will generally have higher velocities than pressure conveying.

Country of Origin : India

Type : Vacuum Conveying System

Certification : CE Certified

Weight : 100-500kg, 2000-4000kg

Voltage : 440V

Condition : New

Automatic Grade : Semi Automatic

Driven Type : Electric

Brand Name : SHREE GURU

Material : SS

Power : 1Hp to 25Hp

Voltage : 380-415 V AC 50Hz

...moreTwo Stage Transformer Oil Filter Machine

125,000 Per Piece

1 Piece (MOQ)

Peculiar Features : Sophisticated design. Easy to operate. Capacity ranging from 100 LPH to 25000 LPH. Imported High quality Filters for best results. Negligible Maintenance. Easy to replace Filters/heaters Digital Temperature monitoring and controlling. Can be completely customized as per the requirement of customers, which makes it user friendly.

Country of Origin : India

Material : Mild Steel

Shape : Square

Voltage : 220V

Condition : New

Motor Power : 2HP

Warranty : 1 Year

Operating Type : Semi Automatic

Power : 5Kw

Filter Length : 2 Inch

Overall Weight : 200Kg

Filtration Capacity : 10 Microns

Flow Capacity Range : 200cfm

Material : OIL

...more

Transformer oil filtration plant manufacturer india

185,000 - 250,000 Per Sets

2 Set (MOQ)

High-Vacuum Transformer Oil Filtration System And Dehydration Plants are suitable for all types of electrical insulating oils. We have standard high-vacuum filtration and dehydration plants to remove moisture (free as well as dissolved), gases, dirt and oxidation products from mineral-based and synthetic, silicone oils and others. Custom built plants can be provided as per customer’s specific requirement, such as more flow-rates. These plants work on low temperature, high vacuum principle. Plants mainly consist of heating, filtration, and vacuum system. Heating system aids to the filtration and moisture removal. Filtration systems remove suspended particles down to 1 micron such as dust, dirt, scales, colloidal carbon etc. Vacuum Systems remove moisture (emulsified as well as dissolved) down to < 5 – 10 ppm depending on the working vacuum of the plant.

Country of Origin : India

Type : Transformer Oil Filtration Plant

Certification : CE Certified

Application : Filtering Transformer Oil

Weight : 1000-2000kg

Color : Blue

Voltage : 110V, 220V, 380V

Condition : New, Used

Automatic Grade : Semi Automatic

Power : 1-3kw

Driven Type : Electric, Pneumatic

Warranty : 1year

Brand Name : SHREE GURU

...more

Transformer Evacuation System

125,000 Per Piece

1 Piece (MOQ)

Brand Name : SGEI

Tank Vacuum Pressure Impregnation Plant

109,000 Per Piece

1 Piece (MOQ)

Voltage : 380V AC

Bag Filling Machine

109,000 - 150,000 Per Piece

1 Piece (MOQ)

Automatic Open-Mouth Bagger (patent pending) is a highly efficient system that has been designed to easily run porous polywoven bags, which are often used in manual bagging operations. offers a new, innovative solution for improved bag separation. Its new technology combines two complementary systems to separate bags at both ends. This is a dependable and efficient solution for porous polywoven bags that could stick together because of static electricity, twisted thread and other reasons. The innovative way to feed bags into an automatic bagger has been merged with the proven robotic full-bag exit system, producing a fully automatic bagging solution that replaces a manual equipment line. This bagger is equipped with devices that detect bag thickness, bag-on-spout placement and an open bag at every step of the process. These detectors spot a closed or misplaced bag on the spout as well as multiple bag picking allowing the machine to reject these bags automatically without stopping the bagging process. All these features are designed to optimize production despite the irregular properties of porous polywoven bags.

Country of Origin : India

Type : Bag Filling Machines

Weight : 100-1000kg

Voltage : 440V

Condition : New

Automatic Grade : Automatic

Warranty : 1year

Driven Type : Electric

Brand Name : SHREE GURU

Power : 2HP

Brand Name : SGEI

...more

Stainless Steel Pneumatic Conveying System

125,000 Per Piece

1 Piece (MOQ)

Brand Name : SGEI

Material : Stainless Steel

Spices Filling Machine with Servo Auger

125,000 Per Piece

1 Piece(s) (MOQ)

Brand Name : SGEI

Application : Packing Food Items

Voltage : 380VAC 415VAC 50/60Hz

Application : Spice Powder

Material : Stainless Steel

Brand Name : SGEI

Automatic Grade : Semi-Automatic

...more

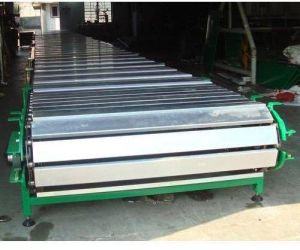

Slat Chain Conveyors System

1,025,000 Per Piece

1 Piece (MOQ)

Slat Chain Conveyor Systems use a slat and chain system to move components along an assembly line. They are often used where production operations are performed with the parts located on the conveyor. Steel panels are attached to the chain with special chain attachments, and the chain is driven by an electric motor and gearbox. Therefore they are one of the most commonly used types of conveyor for moving parts along and assembly line while the work is being performed. They are ideally suited to applications where components are being assembled onto a fixture located at an ergonomic working height. Slat conveyor system also allow production assembly operators to work on one or both sides of the line. Fixtures can be added to the slats to enable parts to rotate 90, 180 or 360 degrees to facilitate better ergonomic access. During model change-overs, the tooling or fixtures can be modified or replaced, and the conveyor is re-used for another new application. In automotive plants, a slat conveyor system may be used to convey parts like instrument panels, center consoles or door trims. They are used for engine and power-train assembly. They are also used for sub-assembly of frames and axles, and on a larger scale even for vehicles after they have been fitted with the chassis components and move to the final assembly line (sometimes known as a ‘flat top’ conveyor line). Customers sometimes call them slat conveyor belts as the slats look and operate like a belt conveyor. TECHNICAL SPECIFICATIONS: Depending upon the conveying application, different lengths, widths, heights, controls and accessories are available to meet the needs. Slats can be made from mild steel, stainless steel or plastic. In some cases the product sits loosely on top of the slats, and in other cases the product is mounted to one or more fixtures. Some typical specifications are shown below, with many more combinations available: 12” – 108” between frame widths (i.e. the width of the conveyor) Speeds ranging from 10 feet per minute (FPM) up to 60 FPM max speed Fixed or variable speed control Adjustable legs Continuous or indexing movement from station to station

Type : Slat Conveyor Base Sewing System

Certification : CE Certified

Weight : 3000-4000kg, 4000-5000kg

Voltage : 220V, 440V

Automatic Grade : Automatic, Fully Automatic, Semi Automatic

Power : 1-3kw, 3-6kw

Warranty : 1year

Driven Type : Electric, Hydraulic, Pneumatic

Material : Stainless Steel

Type : Slat Chain

Power : 3HP

...more

Slat Chain Conveyor India

2,500 - 2,800 Per Sets

100 Set (MOQ)

Slat/chain top conveyor system is designed as a continuous moving type or stop and go type. These products are used in conjunction with roller conveyors to handling cartons and bins in warehouses. These conveyors provide good positive drive and are an economical way of transporting goods. A continuous chain with transverse scrapers moves through a closed rectangular section trough over a horizontal, curve, vertical, or mixed route. The lower length of the chain conveys the product along the bottom of the trough. Applications: Slat chain conveyor slat top chain conveyor can be utilized for long conveyors or large heavy items, conveying glass bottles crates, inline feeders and pressure-less combiners. A continuous chain with transverse scrapers moves through a closed rectangular section trough over a horizontal, curve, vertical, or mixed route. The main structural material is carbon steel galvanized, and stainless steel applicable to food and pharmaceutical industries. Chain plate conveyor line is widely used in pharmaceutical, food and beverage, condiments, daily chemical, chemical, hardware, lubricants, food engineering, dairy engineering, beverage engineering, pharmaceutical, biochemical, brewing and water treatment industries. Specifications: Slat chain conveyor width: 82, 101.6, 114.3, 152.4, 190.5, 254, 304.8 Bend slat chain conveyor width: 82.5, 114.3, 152.4, 190.5, 304.8 Material: Carbon steel, stainless steel, plastic steel (as per different products' requirements to decide related suitable width, shape slat chain to complete planar transferring, turning and screw lifting work.) Features: -"Flex"being able to curve into loops, turn corners, or even form spirals, and is very popular in complex continuous-manufacture systems or bottling/canning plants. -Stable transferring for slat chain conveyor surface smooth and little friction. -Platelets of a slat can be made of stainless steel and engineering plastic etc with various specifications which is selected upon slat conveyor items and process requirements. -Conveyor speed is accurate and stable to guarantee accurate synchronous transmission. -Clean and easy rinse, applicable to foods, soft drinks, breweries, bottling filling, industry, dairy, cheese, etc with strict sanitary requirement. -Simple structure and convenient maintenance. We' re here to listen to your conveyor enquiry and help provide you with complete conveying solutions. Hot Tags: slat chain conveyor, INDIA, manufacturers, suppliers, factory, wholesale, price, for sale, Curved Slat Chain Conveyor, Conveyor Equipment, Turning Powered Roller Conveyor, cross belt sorter conveyor, Slat Chain Spiral Conveyor, Curved Belt Conveyor

Country of Origin : India

Type : Slat Chain Conveyors

Length : 10-20feet, 80-90eet

Color : Blue, Light Green

Condition : New

Load Capacity : 10-15kg, 45-50kg

Brand Name : Mettler-Toledo India Private Limited

Voltage : 415 V AC

Warranty : 1

...more

Slat Chain Conveyor

125,000 Per Piece

1 Piece (MOQ)

Type : Slat Chain Conveyor Systems

Material : Stainless Steel

Brand Name : SGEI

Length : 20-40 feet

...more

single stage transformer oil filter machine

125,000 Per Piece

1 Piece (MOQ)

Features : High Efficiency Longer Life Less Maintenance Less Power Consumption Compact design Economy to the customers Standard synthetic rubber hoses for inlet & outlet Timely services after sales Trouble Free Operation

Country of Origin : India

Material : Mild Steel

Certification : CE Certified

Color : Blue

Voltage : 220V

Condition : New

Motor Power : 4HP

Warranty : 1 Year

Power : 10Kw

Filter Dimensions : 70X70X60cm

Overall Weight : 200Kg

Filtration Capacity : 10 Microns

Usage : Air Filter

Flow Capacity Range : 150cfm

Filter Thickness : 50cm

Operating Pressure : 4

Working Pressure : 4

...more

Single Rotary Screw Nauta Mixer

1,000,000 Per Piece

1 Piece (MOQ)

Driven Type : Hydraulic

Warranty : 1 Year

Brand Name : SGEI

Color : SS

Frequency : 50-60 hz

...more

Semi Automatic Bag Filling Machine

909,000 Per Piece

1 Piece (MOQ)

Automatic Open-Mouth Bagger (patent pending) is a highly efficient system that has been designed to easily run porous polywoven bags, which are often used in manual bagging operations. offers a new, innovative solution for improved bag separation. Its new technology combines two complementary systems to separate bags at both ends. This is a dependable and efficient solution for porous polywoven bags that could stick together because of static electricity, twisted thread and other reasons. The innovative way to feed bags into an automatic bagger has been merged with the proven robotic full-bag exit system, producing a fully automatic bagging solution that replaces a manual equipment line. This bagger is equipped with devices that detect bag thickness, bag-on-spout placement and an open bag at every step of the process. These detectors spot a closed or misplaced bag on the spout as well as multiple bag picking allowing the machine to reject these bags automatically without stopping the bagging process. All these features are designed to optimize production despite the irregular properties of porous polywoven bags.

Country of Origin : India

Material : Stainless Steel

Phase : Single Phase

Corrosion Resistance : Yes

Machine Structure : Vertical

Warranty : 1 Year

Voltage : 110V

Condition : New

Automatic Grade : Semi Automatic

Driven Type : Electric

Power : 10 KW

Dimension (LxWxH) : 580x260x465mm

Weight : 100-500 Kg

Material : SS304/MS

Capacity : 120bag

Brand Name : SHEI

Voltage : 440V AC 50/60Hz

...more

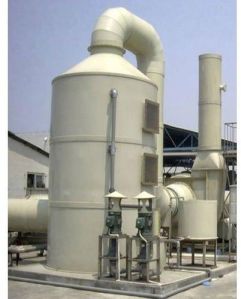

Scrubber Pollution Control System

100,000 Per

1 Piece (MOQ)

Country of Origin : India

Type : Air Scrubber pollution control system

Be first to Rate

Rate ThisOpening Hours

We, SHREE GURU ENTERPRISES INDIA, located in Bidar, Karnataka, India, are a prominent manufacturer and supplier of industrial machinery and accessories. Our product range is organized by our vendors with the particular formation of vital machinery with the aid of classy methods.

We believe in the appropriate quality examination at the time of obtaining to assure the quality of our offered product range on the aspects of eco-friendliness, non-hazardous nature and shelf life. Also, we are equipped with competent marketing managers, research managers, salespersons, obtaining agents as well as packaging teams.

Established in the year 2004 working under the valuable leadership of our CEO Mr Sonu Yadav, we have become one of the prominent names in this business domain. Under his management, we are rising day by day across the world.

Product range

We are renowned for providing numerous classes of industrial use machinery. All these products are manufactured in an exceptionally inventive manner. Our products comprise 10 Outputs Feeders Batch Controller, DLP Lump Breaker, Spices Filling Machine with Servo Auger, Industrial Plants and many more.

Why us?

Severe quality inspection facility by a skilled and capable team of quality controllers

Verifying progressive measures of management and business measures

Supplying quality secure machinery

Using the finest grade of packaging material