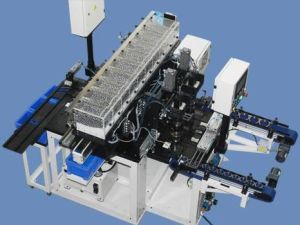

Weighing Printing Machine

Rigid and compact construction Electronic Control system: Using Mitsubishi PLC and HMI touch screen Other PLC can be given as an option Electronic weighing scale of Essae-Teraoka Data log of last 50 cycles Pneumatics: Festo /SMC Label Printers of any make Full safety guard can be given as an option at extra cost Precision check weighing system for missing component detection Various models available depending on component weight: WP-1000: Up to 1000 gm / 0.2 gm resolution WP-3000: Up to 3000 gm / 0.2 gm resolution WP-5000: Up to 5000 gm / 0.5 gm resolution WP-360: up to 30 Kg/10gm resolution Auto component loading and unloading to and from flex link conveyors Cycle time < 12 sec depending on model

...more

Side Loading Washing Machines

Attached with Intralox inlet outlet conveyors Auto loading and unloading for rings. Loading height suitable for manual loading Cycle Time: 16 secs Tooling Setting time < 20 mins Pneumatics: Festo / SMC HMI touch screen 7 inch Switch gears: Schineder, Siemens. Lubrication Unit for Taper measuring station.

...more

visual inspection

High resolution Industrial camera used High reliability Identifies surface defects and missing parts/operation Dimensional measurement not possible. Comparative measurement with good master part. FEATURES Vision system for surface defects and missing parts Camera used as per application High speed working

...more

Spinning Machine

Used for bearing spinning Low cost Simple design Easy to operate FEATURES Available in 3 different sizes Up to 70 mm, 100 mm & above 100 mm Manual operation Manual loading unloading Spinning at low rpm

...more

shielding machine

Applying shields (caps) for sealing of bearings Checking of torque to ensure the fitment of shields Cycle time: 5 sec Tooling setting time < 20 mins Measuring station for shield fitment checking FEATURES PLC Control system: Mitsubishi / Delta Pneumatics: Festo / SMC HMI touch screen 7 inch Switch gears: Schneider, Siemens. Precise measurements using Std LVDT probes

...more

Semi Automated DGBB Line

Digital Display for IR OR measurement Manual Ball loading single ball Magazine Manual Cage feeding Available in three different ranges 62 mm, 100 mm & 160 mm Low cost Suitable for small lot operation. FEATURES Manual sorting of IR and OR Automatic Ball filling with single ball Semi-Automatic Cage fitting operation PLC based control system Compact, robust and efficient design

...more

Rotary Hopper

SMT offers a wide range of Rotary sizes, Disc formations and exit feeding options to suit most customer needs. Let SMT Systems design, select and custom build your Rotary application to give you the reliable, efficient and feeding solution as per your requirement Different diameter range as per customer requirement. Rotary or vibratory option available Suitable for feeding application No damage to the parts Maintenance free design

...more

Roller Grading Machine

Compact and robust design Very High speed operation High accuracy Better gauge repeatability and reproducibility. Range bound design as per size and weight of Roller. FEATURES Available in different sizes Grading in 12 grades in range 2 µ High Speed operation 80 - 200 rollers/min Tool setting time < 20 min PLC: Mitsubishi or equivalent Measuring System developed by SMT.

...more

Ring Feeding Machine

On line ring supply machine for finished rings Suitable for inner and outer rings Manual loading of the rings required Loading height suitable for manual loading Auto unloading on outlet conveyor Careful handling of the rings so that no ring damage will take place On line ring supply machine for finished rings Suitable for inner and outer rings Manual loading of the rings required Loading height suitable for manual loading FEATURES Rigid and compact construction. PLC Control system: Siemens / Mitsubishi / Delta Pneumatics: Festo / SMC HMI touch screen 6 inch Compact design (more that 40% space saving over a buffer conveyor) Buffer storage capacity: 35 min to 45 min (depending on ring geometry) Auto unloading on outlet conveyor Careful handling of the rings so that no ring damage will take place Operating range: 20mm to 62mm of rings

...more

Radial Clearance Machine

Bearing rotation; precise and smooth achieved using precision spindles driven by AC servo motors Programmable sorting tolerance bands Operating range (Bearing OD): 30mm to 62mm Sorting classes (compartments): 4 + 1 Cycle time: as low as 2.5 sec Resetting time: 15 minutes Rigid and compact construction Measuring resolution: 0.1 µ Repeatability: within 2 microns (on master under standard operating conditions) Simultaneous bore measurement as an option Control system: Siemens / Mitsubishi /Delta Bearing rotation motors: AC servos by Delta / Panasonic Measuring head: SMT Measuring Instrumentation: SMT LVDT probes: Marposs Pneumatics: Festo CORNERS

...more

Printing Machine

Label printing based on weight check Weighing capacity: 3Kg for WPR-30 (other options on request) Least count: 0.01 gm TFT Touch screen for easy visualization and control Printing label width up to 100mm. FEATURES Facility for setting of Min & Max weight range on HMI screen Printing only when weight is within acceptable range Three lamps to indicate weight less than limit, within limit, greater than limit Label printing arrangement with printer & Format setting Component type wise parameter saving and retrieving facility Data log facility; Data can be copied on USB in CSV format

...more

Missing Component Detection Machine

Missing component detection in ball bearings Capable of detecting missing balls, missing rivets, missing cage Precise inspection of bearing rotational freeness Bearing rotation; precise and smooth achieved using precision spindles driven by AC servo motors Separate rejection chutes for missing component and free run NGs Operating range (Bearing OD): 30mm to 62mm Sorting classes (compartments): 2 + 1 Graphical representation for each test for better user friendliness Easy and quick master calibration facility Cycle time: as low as 2.0 sec Resetting time: 15 minutes Rigid and compact construction Excellent fidelity and repeatability in results Simultaneous inspection of all specified defects Control system: Siemens / Mitsubishi / Delta Pneumatics: Festo / SMC Full safety cover with transparent windows

...more

Inspection Machine

Bearing's cup checking Measure: ID (Taper): within 5 µ,, OD : within 3 µ, Width : within 10 µ Washing of the cups Cycle Time: 16 secs Automatic master calabration feature Repeatability : OD< 1 µ, Taper< 5 µ, Width < 5 µ. Tooling Setting time < 20 mins Universal measurement station, sutable for all diameter and heights within machines oerating range

...more

grease filling machine

Usage : Industrial

Bore Measurement Machine

Measuring machine for bore measurement and control Auto component loading; auto measurement and auto unloading Other size machine models can be developed on request) Parameters being checked: Diameter (in two different planes), Ovality (out of roundness) and Taperness Component is under rotation while measurement Cycle time: 3 sec, 5 sec and 8 sec respectively Measuring system resolution: 0.1 µ and repeatability within 1 µ Various component sizes within permissible range can be handled by resetting the machine using change tooling

...morebeacon

It is being used as measuring instrument. used in various industrial precision measuring applications It can be integrated with any PLC/ Controller on automatic machines or can also work independently on a test bench component inspection, grading and pairing of bearing races such as DGBB, TRB, SRB, HUBs etc, seal or shield inspection,radial or axial clearance measurement, shim selection FEATURES PLC Control system: Siemens HMI touch screen 10 inch Presice measurements using Std LVDT probes Switch gears: Siemens. Data Logging, Alarms, Real time Run Chart display

...more

Auto Spinning Machine

Uniform spreading of grease dispensed between inner and out bearings Cycle Time: 5 sec Careful handling of the rings so that no ring damage will take place Tooling Setting time < 15 mins FEATURES PLC Control system: Siemens / Mitsubishi / Delta Pneumatics: Festo / SMC HMI touch screen 7 inch Servo motors to achieve position accuracy Switch gears: Schneider, Siemens Processing of 4 bearings at a time Data Logging, Alarms, Real time Run Chart display

...more

Auto Riveting Machine

Auto ball separation station Female cage feeding station Male cage feeding station Male cage presence check Female cage presence check Component assembly (Male and female cages with bearing) Pre-pressing ( For diameter 72mm and above) Press (hydro-pneumatic) Final control (missing or un-pressed rivet) NG sorting Unloading Male cage and female cage stock to be loaded manually Stock capacity (10 minutes) Cycle time: 3.5 to 4 sec Resetting time: 60 minutes PLC: Siemens / Mitsubishi/ Delta HMI: 6 or 7 inch touch screen operating panel Measuring sensor: Marposs / Tesa Measuring sensor signal conditioner: SMT Pneumatics: Festo / SMC Switch gears: Schneider, Siemens. Data Logging, Alarms, Real time Run Chart display

...more

Auto Pairing Machine

Auto loading of IR and OR from inlet conveyors. Track measurement by 3 point / multipoint measuring head Ring buffer (Storage) capacity of 10 rings IR and 10 rings OR Ring matching Auto ball filling (ball variety 10 no's) Single axis servo mechanism for bal collection and delivery Auto ball filling, Auto separation of unmatched bearings with component segregation Cycle time: 3.5 to 4 sec. Resetting time: 120 minutes PLC: Siemens / Mitsubishi/ Delta HMI: 10 inch touch screen operating panel Measuring sensor: Marposs / Tesa Measuring sensor signal conditioner: SMT Pneumatics: Festo / SMC Full safety guard with interlock

...more

Alpine Conveyor

Used as buffer in between the machines Available as per customer requirement Easy for set up Custom made designs Available in different lengths and heights

...moreBe first to Rate

Rate ThisOpening Hours