Paint Kitchen

Get Price Quote

Under the strict vigilance of our adroit professionals, we are providing an innovative collection of Multicolour Paint Kitchen System. It comes with Pneumatic agitator for different capacity paint tanks, the offered kitchen system is designed at our premises by using quality tested material in adherence with quality norms. This kitchen system is stringently tested on numerous defined parameters so as to dispatch a flawless range. Special Features Precisely engineered. Smooth functioning Excellent capacity Application Area Automobile Industry Defence Drums & Barrel General Engineering Leather Industry Metal Heavy Engineering Ceramic Industry Wood / Plastic

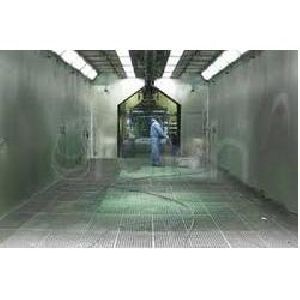

Paint Booth

140,000 - 250,000 Per Piece

1 Piece (MOQ)

We are the main supplier of this product. as per client requirement , after visit we suggest & deside & consult to client which is best & better for the requirement perticular for the job, then put up our offer.

Best Deals from Spray Painting Equipment

Wet Type Downdraft Paint Booths

Get Price Quote

International standard design & fully modular construction. Sutaible for painting Medium & Large type of components. Direct / Belt driven centrifugal blowers or axial fan with motors. Option of flame proof motors and flame proof illumination. Supplier with push button starter or electrical control panel. Simple & low cost maintenance. Continuous bottom water flow. Available in sliding or automatic doors. Complies with current health and safety legislation.

Paint Kitchen Room System

Get Price Quote

In this system, Paint is carried from Paint is stored, Mixed for proper viscosity, also can be kept for suitable temperaure. Paint Room is especially designed for Paint feeding system, Vapour of Paint & Thinner are directed through air Blower with proper Input Filter . Paint is carried through Stainless Steel pipes towards Spray painting Booths or Sttions. Prapat, the paint transfer pump in the paint spraying system is used for ensuring uninterrupted, uniform and filtered paint feeding to the spraying gun. The pneumatically operated piston type pump is a compact and sophisticated option to the conventional pressure feed container. Prapat provides uniform and easily controlled delivery. The easy to monitor, sleek design and light weight ensures great reduction of paint wastage in the painting process. Advantages :• Uninterrupted paint feeding.• Quick and easy colour change.• Lower rejects as paint is uncontaminated.• Savings in paint due to minimum wastages while cleaning/ colour change operations.

Graco Paint Tube

330 Per Meter

fiberglass filter material

Get Price Quote

With sincerity and hard work of our experts, we have carved a niche for ourselves in this domain by offering Fiberglass Filter Material. The offered material finds wide usage in filtration process. The provided material is woven using superior quality fiber and cutting-edge technology in tune with defined industry standards. We provide this material in several sizes as per the requirement of our clients. To ensure the quality, this material is stringently checked against practical parameters by our quality experts.

Andreae Paint Booth Filter

550 Per piece

5 piece (MOQ)

Air Assisted Airless Spray Painting Machine

150,000 - 7,000,000 Per Piece

1 Piece(s) (MOQ)

We are one of the preeminent Distributor of Air Assisted Airless Spray Painting Equipment in the market. Our range of Assisted Airless Spray Painting Equipments are designed to provide sprayers at competitive prices, robust industrial assembly, able to apply a wide range of industrial coatings whilst providing the very best quality of sprayed finish. Our Range : Manual Air Assisted Airless Spray Painting System Automatic Air Assisted Airless Spray Painting System Special AAA Systems with Sealless/without seal Pump Attributes : Available with extension for Internal Pipe ID and inside Cavity Painting High productivity 20 to 30% savings over HVLP – Material & Air cost savings Reduced over spray, reduced VOC emissions User friendly and very reliable 360 Deg. rotating Gun – Thanks to Swivel Fitting for Paint and Air hose Compatible with water-based products Complete ‘V’ shape Flat pattern help to get uniform and very fine finish Lightweight, Easy Trigger Pull Reduces overall cost of ownership Improving transfer efficiency and material usage Versatile spraying of all shapes and sizes Heating system available for temperature sensitive material if required Applications : Furniture industry Wood industry Handicraft industry Wind Sector industry Leather industry Plastic industry Locomotive painting Metal industry Marine industry Gives Excellent Results with : Stains Sealers Melamine Acrylics Enamels Polyesters Polyurethanes Ceramic coating Water-based products Lacquers, Waxes Metallic & Non-Metallic Paints Varnishes

Paint Booth Ceiling Filter

550 Per Piece

50 Piece (MOQ)

Car Paint Booth

Get Price Quote

1 Piece (MOQ)

Rotary Atomizers

Get Price Quote

Rotary Atomizers are used in Spray Drying for atomizing the feed into fine droplets. In Rotary Atomizers, the kinetic energy of wheel rotation is used for atomization of the liquid. Droplet size of atomized liquid depends upon liquid properties, disc speed, disc configuration etc. Bulk density is also one of the critical product requirement of spray dried products. The desired results can be achieved by using different Atomizer wheel configurations and optimizing atomizer speed, optimizing relevant feed properties

Two Component Spray Painting Systems

Get Price Quote

Paint Booth

Get Price Quote

Product description: We are the leading provider of Paint Booth. About us Our organization, Sairang Engineers, was established in the year 2018, as a prime manufacturer and trader of Clean Room Products. We have earned ourselves a place amongst the top producers within the industry due to the manufacture of our indisputable line of products which include Laminar Air Flow Unit, Static and Dynamic Box and Modular Clean Room Panel amongst a range of others. Our efforts remain in the upkeep of client satisfaction through consistent hard work and perseverance. We ensure a set level of open ended communication to help tend to the needs of the client in a personalized manner. We maintain ethical business practices and exercise cordial relations in all our dealings. We welcome new client based on an association of mutual benefit and trust. Our position within the industry is attributed to an infallible infrastructural base that encapsulates our organization. Each department within the organization is segregated for the purpose of coordinated work flow between units. Our manufacturing unit makes use of technology and high-tech machinery to manufacture our unique products. Our products are specialized at providing safe and sterilized environments for handling bio-hazardous and susceptible samples. Our air chambers create environment segregations to prevent external air from contacting the samples and internal air from exiting into the environment.

Graco Spray Painting Equipment

405,000 Per Units

Spray Painting Booth

Get Price Quote

We source direct as well as indirect raw materials only from the certified vendors present in the market. Our team of quality experts strictly checks the entire range against varied parameters. Owing to our immense expertise in this domain, we have carved a niche as a Supplier of Spray Painting Booth in the market.

Liquid Painting Booth

Get Price Quote

Liquid Painting Booth, automatic spray painting, coating equipment

Control Spray HVLP Sprayer

30,000 Per Piece

HVLP Sprayer

30,000 Per Piece

Airless Spray Painting Machine

1,350,000 Per unit

cabinet type spray washing machine

Get Price Quote

FRONT LOADING & UNLOADING CABINET WASHER Cleanster Machine built cabinet type spray washing machine with rotary table and designed for large size and batch cleaning process, while retaining the cost-effectiveness of the equipment. Cabinet type cleaning machine are available in different turntable/ fixed square baskets sizes ranging from 600, 800, 1000, & 1200 mm dia. and have loading heights to meet the requirement of your process. Cabinet type cleaning machine can be customized and is available in single chamber, common point load / unload with single or multi tank with multitier filtration system suit your specific application requirements. These equipments can be designed with independent component rotation/ fixed for specific parts. Programmable control panel with human machine interface (HMI). High Pressure Spray nozzles for internal cleaning. Suitable for large parts, machined bodies and batch type production. Operation of the machine :- The parts to be cleaned are sprayed with a high flow via the spray bars, which rotate either through spray pressure or a mechanical drive. The spray bars are mounted with flat pattern nozzles, which provide efficient cleaning results. The machines are fully insulated with stainless steel panels, and therefore the wash water can be heated up to 90°C. Normal working temperature is from 60 - 75°C. Design and user friendliness:- The R 6272 A is designed totally in stainless steel both inside and out. To give the machine a more simple and neutral appearance, we have integrated a lot of components into the machine. The system has a compact construction, which makes it easier to operate. On the outside, you will find only the control panel. From this it is easy to programmed and operate the machine and make various adjustments, such as setting the speed and temperature of the separate wash tanks. At Cleanster machines our objective is to produce high quality, reliable equipment. Therefore we work carefully with all the details on our systems, but reliability is always the most important consideration. We also strive to make our machines look good. We design all our machines, so they appear functional and simple. Therefore you will find few external components on our machines. Noise of machines are minimized by integrating any noisy parts into levels the internal framework construction of machines and then using sound insulating panels. With Cleanster Machines you get a reliable and simple machine – with the functions you need. Our manufacturing philosophy is “The fewer the parts, the better the quality!” Wash day and night The R 6272A Cleaner is perfect for installation in any production lines, where machines have to run continuously for 24 hours. The machine is equipped with an efficient return flow system, which returns the cleaning solution through a filtration system to the wash tank. The wash water is continuously filtered and collects any loose debris from the components. On the pressure side of the pump system, efficient pressure filters are installed to prevent nozzles blocking, which could otherwise reduces the cleaning performance.