welding consultancy services

SV Tech has the technical ability to provide WPS, PQR, WPQ, Welding Procedure and Welder qualification as per ASME, AWS, EN and API. Welding Procedure Specifications - WPS • A WPS is a written (qualified) welding procedure prepared to provide direction for the making of production welds • The completed WPS shall describe all of the essential, nonessential, and, when required, supplementary essential variables Procedure Qualification Record - PQR • A PQR is a record of welding data used to weld a test coupon • It is a record of actual variables recorded during the welding of the test coupons Welder Qualification • Welder certification, (also known as welder qualification) is a process which examines and documents a welder’s capability to create welds of acceptable quality following a well-defined welding procedure. • Welder qualification is limited by essential variables given for each process

...more

Ultrasonic Testing Services

Ultrasonic Testing is family of Non Destructive Testing Techniques best on the propagation of ultrasonic waves in the object or material tested. There are two methods of receiving the ultrasound waveform, reflection and attenuation. In reflection (or pulse-echo) mode, the transducer performs both the sending and the receiving of the pulsed waves as the "sound" is reflected back to the device. Reflected ultrasound comes from an interface, such as the back wall of the object or from an imperfection within the object. The diagnostic machine displays these results in the form of a signal with an amplitude representing the intensity of the reflection and the distance, representing the arrival time of the reflection.

...more

Third Party Inspection Services

S V Tech provides Third Party Inspection and Verification Services to customers with Quality and Accuracy. Our third party vendor inspection service that ensures product quality and timely delivery. We check equipment and plant meets your requirements before it leaves a supplier, therefore cutting the risk of production outages and subsequent threats to safety, asset integrity and legislative compliance. Our qualified and experienced personnel are permanently located in all cities around the state. This truly gives you a cost effective service by minimizing travel and accommodation time and costs.

...more

Tensile Testing Services

Test name: testing on universal testing machines about the test: tensile test on: plates, pipes, bars etc. Wires/ thin foils fine wires/foils with graph tensile test/ breaking load test on tmt / tor steel bar with yield stress, uts, %elongation, stress strain graph, young's modulus, proof stress at 0.1%, 0.2% & so on this test is widely used to determine strength, ductility, resilience, toughness and several other material properties. A test specimen of circular, square or rectangular cross-section of a suitable size is prepared from the material to be tested. The specimen is held by suitable means between the two heads of a testing machine and subjected to a progressively increasing tensile load till it fractures. A record of load acting on the specimen with progressive extension of the specimen is obtained.

...more

radiography testing services

Radiography testing (rt) is used to perform inspections that detect internal discontinuities in all material types, and can be an option for both field and shop work. Rt is predominantly used for weld inspection or the testing of castings and forgings using one of two source types, x-ray or gamma ray (isotope) radiation. Radiography-testingusing radiography, the part is exposed to the source while a film is positioned behind the part to be inspected. The film is then developed and is reminiscent of a film negative. Based on the actual indications on the film and density differences a determination can be made regarding the size and orientation of imperfections within the material as well as the their location relative to the weld. We are then in a position to determine whether or not the defect passes or fails based on the accept/reject criteria within the codes.

...more

Pmi Testing Services

SV TECH Engineering enhances its Non Destructive Testing offering with Positive Material Identification service. SV TECH's on-site inspection and testing team has multiple highly sophisticated handheld / portable X-Ray Florescence (XRF) Spectrometers which can measure the chemical composition of the materials, non-destructively and accurately. The range of equipment available for undertaking Positive Material Identification (PMI) at SVTECH is unparalleled in India.

...more

Metallography Testing Services

These are very widely used in characterizing the material. Various phases in an alloy system are quantified and the extents of their presence are correlated to the properties like strength, corrosion resistance, stability of the material, etc. The micro structure reveals the grain structure whether as cast, wrought, heat treated or subjected to any special treatment such as carburizing, hardening etc. This also reveals the presence of carbides particularly Chromium carbide which is a matter of concern in high chromium, nickel alloys. Tests under Micro Scope: Micro Examination with Photographs Micro Examination for Welded Pipes Macro Examination for Forgings, Mock-ups, Fillet Weld, Grain Flow Macro Examination for Pipes Weld Penetration Test with measurements and photographs

...more

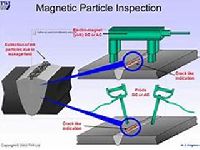

Magnetic Particle Testing Services

This process used for detecting surface and slightly subsurface discontinuities in ferroelectric materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The reason we use this test is to find small defects in objects before they become bigger defects and cause serious problems. In magnetic particle inspection, a magnet or electrical current is used to establish a magnetic field in the object. Iron filings are then dusted on to the surface of the object. The filings should align along the magnetic lines of force. If a crack or other defect is present, the magnetic lines of force will be disrupted and the magnetic particles will cluster along the edges of the flaw.

...more

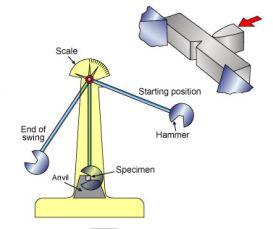

Impact Testing Services

SV Tech has facilities for Impact Tests as per ISO Standards as well as American Standards (ASTM) Izod/Charpy Impact Tests on IS / BS / ISO Machine Under certain situations, a ductile material fails in a brittle manner in the service and such a failure is characterized by low absorption of energy. The factors which contribute to the brittle type of failure are: A tri axial state of stress, A low temperature and A high strain rate or rapid rate of loading. Charpy impact test is widely used in the United States and Izod impact test in Great Britain for this purpose. Procedures for the Charpy and load tests as applied to metals have been standardized (ASTM E 23).

...more

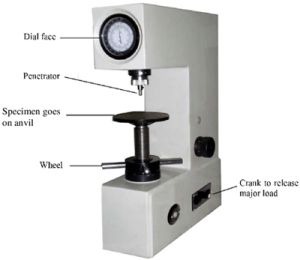

Hardness Testing Services

Various types of hardness like: rockwell hardness brinell hardness vickers hardness micro hardness test (10 gms to 1 kg) hardness by portable tester equipments we use: vickers cum brinnel hardness testers brinell hardness testers. Micro hardness tester.

...more

Eddy Current Testing Services

This ndt method is based on the principles of electromagnetic induction. The flow of electricity, under certain circumstances, can cause magnetism. Magnetism under certain circumstances causes the flow of electricity. When an alternating current (ac) is passed through a coil, a changing magnetic field is generated. This method can be applied to tubing, sheets, cylinders and coatings and provides a means for measuring conductivity, detecting discontinuities, and determining the thickness of coating or plating on articles. Since a continuous indication is a part of the basic testing system, automatic production testing is particularly feasible.

...more

dye penetrant testing services

Dye penetrant inspection (DPI), also called liquid penetrant inspection (LPI) or penetrant testing (PT), is a widely applied and low-cost inspection method used to locate surface-breaking defects in all non-porous materials (metals, plastics, or ceramics). The penetrant may be applied to all non-ferrous materials and ferrous materials; although for ferrous components magnetic-particle inspection is often used instead for its subsurface detection capability. LPI is used to detect casting, forging and welding surface defects such as hairline cracks, surface porosity, leaks in new products, and fatigue cracks on in-service components. The test surface is cleaned to remove any dirt, paint, oil, grease or any loose scale that could either keep penetrant out of a defect, or cause irrelevant or false indications. Cleaning methods may include solvents, alkaline cleaning steps, vapor degreasing, or metal blasting. The end goal of this step is a clean surface where any defects present are open to the surface, dirt, and free of contamination. Note that if metal blasting is used, it may "work over" small discontinuities in the part and an etching bath are recommended as a post-blasting treatment.

...more

Digital Hardness Testing Services

SV Tech Engineering offers micro digital hardness testing for various applications. Hardness testing can be performed on a variety of materials. Both new construction and in-service components can utilize this testing method. The equipment is portable so let us bring our service to your job site. We offer a complete range of Hardness Testing for quick and convenient on-site hardness testing. Hardness Testing is to verify the heat treatment of a part and to determine if a material has the properties necessary for its intended use. Hardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also refer to resistance to bending, scratching, abrasion or cutting. The hardness values are determined by measuring either the depth of indenter penetration or the size of the resultant indent.

...more

chemical analysis services

These instruments meet your requirements of fast and urgent analysis of ferrous and non-ferrous metals and alloys in shortest span of time i.e. 30 seconds. Highly accurate and dependable instruments which are specially tailor- made to suit requirements of our customer, calibrated with reference materials traceable to international standards. Capable of Analysis of All Ferrous Metals & Non-Ferrous Metals by Spectrometry, including Copper, Aluminium, Nickel, Cobalt and Titanium Alloys.

...more

Borescope Inspection Services

This is an optical device consisting of a rigid or flexible tube with an eyepiece on one end and objective lens on the other linked together by a relay optical system in between. In some cases, the optical system is surrounded by optical fibers used for illumination of the remote object. Borescopes can be used for visual inspection work where the area to be inspected is inaccessible by other means. Borescopes are commonly used in the visual inspection of aircraft engines, aero derivative industrial gas turbines, steam turbines, diesel engines and automotive and truck engines. Gas and steam turbines require particular attention because of safety and maintenance requirements. Borescope inspection of engines can be used to prevent unnecessary maintenance, which can become extremely costly for large turbines. They are also used in manufacturing of machined or cast parts to inspect critical interior surfaces for burrs, surface finish or complete through-holes. Other common uses include forensic applications in law enforcement and building inspection, and in gun-smithing for inspecting the interior bore of a firearm.

...more

Bend Testing Services

Bend test is mainly done to check ductility of the material and the resistance of the metals to cracking during distortion. From the test maximum bending strength can be determined and the presence of the cracks can easily be revealed. In this test, specimen is subjected to progressive localized overstressing. The test is very simple and requires less time. Conditions for the bend test vary according to various material specifications. Standard sized mandrels are available to bend the specimen to the required angle. The angle which is specified is the internal angle of bend. After bending, the convex surface of the bend is examined for evidence of a crack or surface irregularity. If the specimen fractures, the material has failed the test. When complete fracture does not occur, the criterion for failure is the number and size of cracks or other surface irregularity visible to the unaided eye occurring on the convex surface of the specimen after bending, as specified by the product standard. Any cracks within one thickness of the edge of the specimen are not considered a bend test failure. Cracks occurring in the corners of the bent portion shall not be considered significant unless they exceed the size specified for corner cracks in the product standard.

...more

Third party Inspection

Welding Consultancy

ndt training institute

ndt equipment

material testing laboratory

Manpower Support Service

ndt training services

Non-Destructive Testing (NDT) training is generally necessary that the candidate successfully completes a theoretical and practical training program, as well as have performed several hundred hours of practical application of the particular method they wish to be trained in.

...more

ndt consultancy services

With our domain expertise in NDT, we have the capability to provide consultancy services in all aspects of NDT solution. To offer our customers with world class solutions, we have developed strong alliances and strategic partnerships with various players in the industry. This along with support of our team of experts offers us with leverage to gain competitive advantage in the industry.

...moreBe first to Rate

Rate ThisOpening Hours