Weighing Controller Standard

The Weighing Controller standard is a newly developed controller with a high performance weight scanning system and improvised logic. The controller is field tested and proven on several linear weigh filler machines and has given superb results considering the accuracy and speed. The prominent features developed in the controller are as below: Features: High speed weight sampling. Multi recipe storage. Relay and transistor outputs. Multifunction keypad. Avaliable in high contrast amber coloured OLED display for viewing over long distances. 24vdc operation Compact size and light in weight Easy to use and setup Single step calibration. Auto-zero tracking and adjustment. Pouch Counter. Weight totalizer 0-10vdc analog output Inbuilt vibratory speed control facility in digital form Size in mm: 192 x 96 x 80 Easy integration with PLCs over simple IO logic.

...more

Volumetric Filler form fill Seal Machine controller

The volumetric (cup) Filler vertical form fill seal controller is derived from the basic packaging controller unit with and additional cup filler control mode functionality. The standard cup filler machines require perfect synchronization when operated in start-stop modes and multi drop modes. This controller has the logic that takes care of all the cup filler and FFS related operations Specifications: Output list: Pulling clutch-brake control. Horizontal sealing Vertical sealing. Batch cutter and perforation cutter. Nitrogen flushing. Batch coding/printer. Conveyor motor output. Cup Disc motor ON/OFF control. Vibratory feeder o/p for material flow control. Input list: Photomark sensor Machine proxy sensor Disc proxy 05 extra inputs. Configurable delay times and hold times for all the operations. Cup Disc can be operated in single cycle or start stop control mode. Pouch counter. Front panel I/O indicators. Power: 24Vdc. Dimensions: 144mm x 96mm x 175mm (L x B x D).

...more

Touch-Logic Series Programmable Controller

The Touch-Logic series programmable logic controllers are designed for general industrial control applications that can be interfaced with standard industrial HMI panels for display purpose. These controllers are currently being manufactured for high speed form fill seal machines with several filling mechanisms. Numerous applications can be developed with this controller since on-site program change and debug facility is possible with this controller. These controllers are provided along with a HMI with software designed as per the user’s application. Applications: This controller comes pre-programmed with the logic for the below applications: VFFS machine control. Synchronization of upto 5 linear weigh filler heads with VFFS bagger machine. Auger filler with VFFS bagger machine. Volumetric cup filler with VFFS bagger machine. Bagger unit of combinational multihead machines.

...more

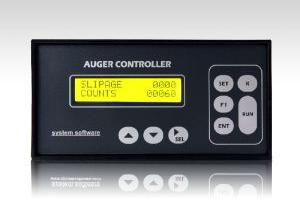

Semi-Automatic Auger Controllers

These controllers are designed for standalone auger filler machines that have to only control the auger screw rotations as per the user’s required counts or timing. They are mostly used in foot-switch operated semi-auto auger machines. Specifications: Auger clutch brake control output. Conveyor motor control output. Encoder input. Auger slippage indication. Run-time changing facility of auger counts. Timer or encoder based operation. Auto or manual mode of control. 24vdc operation. Size: 144mm x 72mm x 100mm ( L x B x D)

...more

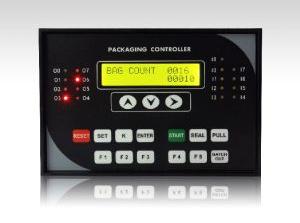

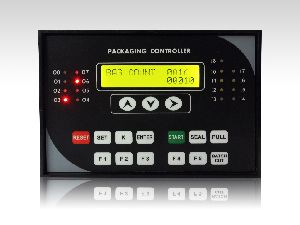

Packaging Controller Standard

The Packaging controller standard, popularly known as Master Controller, is a compact easy to use controller to perform the bagging related operations of the packaging VFFS machines. This controller has 9 outputs and 9 inputs and can be interfaced with all the sensors, coils and motors used in any standard FFS/VFFS machine. Designed with an intelligent logic and fail safe electronic hardware, this controller provides a standalone solution for all types of fully automatic/ semi-pneumatic/ fully pneumatic FFS machines. Specifications: Output list: Pulling clutch-brake control. Horizontal sealing Vertical sealing. Batch cutter and perforation cutter. Nitrogen flushing. Batch coding/printer. Conveyor motor output 02 extra outputs. Input list: Photomark sensor Machine proxy sensor 06 other extra inputs. Configurable delay times and hold times for all the operations. Pouch counter. Front panel I/O indicators. Power: 24Vdc. Dimensions: 144mm x 96mm x 175mm (L x B x D).

...more

Dual Head Weighing Controller

The dual head weighing controller is the industry’s one of its kind controller designed exclusively for weighing based control systems where simultaneous control of two weighing systems is needed. The controller is designed to be fitted in the machine’s panel box. The controller uses an external HMI unit which displays all the programmed parameters in real time. the dual head weighing controller can be synchronized with several of its kind of controllers together to obtain multiple weighing controllers working together with shared resources. The firmware of this controller is designed using high performance 32-bit controllers with real-time operating system. This facilitates optimum performance of the control actions along with communication over standard industrial protocols. Specifications: Direct Loadcell interface over two independent analog input channels. Sixteen transistor outputs of 10watt each. Six digital inputs. One Rs-232 communication port. One RS-485 communication port. Simultaneous sampling of both the Loadcell signals at high speed. Two Analog outputs. Easy to use and setup. Multiple recipes per weighing head. Auto zero tracking and adjustment. 24vdc operation. Size in mm: 220mm x 60mm x 45mm

...moreBe first to Rate

Rate ThisOpening Hours