Water Jet Cutting Machine

1 Piece(s) (MOQ)

Designed with perfection, our Water Jet Cutting Machine is reckoned for its strong built, high performance features and easy operatability. We are Maharashtra, India based Supplier and ensure that the finest lot of Machines reaches the buyers. For this, we check the product quality prior to procurement and final dispatch. Furthermore, we offer it at cost effective prices, for the ease of the buyers. More about Water Jet Cutting Machine The cutting table comprises a precision-built steel construction embodying linear direct-drive motors on each of the two main axes. To achieve the required precision, the bridge and self-propelled carriage plate are powered by two direct-drive linear motors on each side. This results in a speed range from 1 to 30.000 mm/min. Use of these components and construction enables the installation to achieve positioning accuracy and repetition accuracy of ± 50µm (at 20oC) across the machine's full range. The guide ways and drives are suitably protected from water and abrasive through bellows and protective stainless steel plating. Direct-drive linear motors guarantee : Better cutting behavior and absolute repetition accuracy (without needing to back-up) of the cutting head compared to traditional mechanical transitions using spindle, pinion, rack and gears. Low maintenance as a result of the non-contact principle, combined with greatly reduced wear parts consumption. Wide range of cutting speed and jogging speed, adjustable from very low to very high. Fast response enables cutting speed to be rapidly changed. Unmanned ProductionDue to automatic control of the PJ high pressure pump and the process parameters, permanent supervision during the cutting process is not required. Resato water jets are equipped with an automated stop function that trips once a cutting task is completed. This means that all units will be acting in standby mode or will shut down and almost no energy is required.

Country of Origin : Pune

...more

used boring machine

5,000,000 Per Piece

Folding Machine

1 Piece(s) (MOQ)

PTL A machine designed for zinc specialised worshops, also shop fi ttings, insulation, aluminium and thin sheet metal work Entirely electric control The PTL bender is fast, fl exible and easy to use Standard equipment � Pedal operated clamp control, for hands free operation � Push button apron control � Electromechanical angular gauge from 0 to 145° � 12 mm apron including interchangeable 15 mm tool (total width 27 mm) � Adjustable bending radius � Dishing device on the table and the apron � Interchangeable clamping tool curved on 35° to provide the U profi le Universal benders PTL 35° 27 A 12 15 Numerical control on PTL and PTN A = minimum 12 times the thickness Features PTL2050-15 PTL2550-12 PTL3050-10 Useful bending length (mm) 2 050 2 550 3 050 Capacity (mm) * Apron 12 mm Apron 27 mm Apron 12 mm Apron 27 mm Apron 12 mm Apron 27 mm Steel S235JR 1,0 1,5 0,8 1,2 0,7 1,0 Alu 1,5 2,0 1,2 1,8 1,0 1,5 Power kw 1,75 1,75 1,75 Dimensions not including back gauge AR (mm) 2 705 x 620 x 1 190 3 205 x 620 x 1 190 3 705 x 620 x 1 190 Gross weight (kg) 1 200 1 400 1 600 * Minimum bend width 12 times the thickness in its maximum capacity

Condition : Good

Specialities : Standard equipment ,Pedal operated clamp control, for hands free operation,Push button apron control

Country of Origin : Pune

...more

Two head automatic pipe drilling machine F2T

1 Piece(s) (MOQ)

Two Head Pipe Punching Machine Specifications: � X- axis stroke 3000 mm�Y- axis stroke 300 mm�Z-axis stroke 100 mm � X axis controlled by PLC, Y axis controlled by PLC, Z axis pneumatic (alternative: controlled by PLC) � Automatic oil mist system for cooling the drilling tool � Number of drilling heads: 2 � Max hole diameter: 15 mm � Power of drilling motor: 2,2 kW � Minimum diameter of the pipe: 20 mm � Max diameter of the pipe : 80 mm - 80x80 mm � Max pipe length: 3000 mm � Control system: PLC Siemens S7 � Display: 15" color touch screen display. � Software: developed by BS

Type : Pipe Drilling Maching F2T

Condition : Good

...more

turret punching machine

1 Piece(s) (MOQ)

We are offering turret punching machine. Techno crafts offers cnc turret punching machine. The boschert multipunch auto tool carrousel is mounted at the front and below table level. product profile : techno crafts offers cnc turret punching machine. The boschert multipunch auto tool carrousel is mounted at the front and below table level. The multipunch tool carrousel is mounted at the front of the machine, below table level. The vertical and horizontal axis movements are controlled by ball screws with linear ball guides using double carriages. The rotary axis positions the eight cassettes with a track and pinion drive. The multipunch uses trumpf style tools up to size ll (3”) and boschert revotools. It is possible to have up to 64 individual tools, which are all fully indexable in the machine. features: fast tool change in 3 up to 5 seconds 28 tons hydraulic punching force high accurate punch guiding system. The tool is fitted directly in the piston so no additional clearance like on turret machines. These feature warranty long tools live on punch and dies smart auto clamp movement system. Very fast set up of the clamps on the required position up to 4 clamps possible (2 standard) auto repositioning up to 10 m for large sheets easy sheet loading system; sheet lifting device 2 pneumatic cylinder to lift the sheets, so that it can be easily moved to the clamps without human handling set of keys and instruction manuals automatic removal of small parts and scrap 300x200 mm waste removal suction system to prevent the slug to move up programmable stroke adjustment multitalk memory extension with usb and lan connection for labod control safety light guards in front of the machine.

Condition : Good

Application : The multipunch uses trumpf style tools up to size ll (3”) and boschert revotools

Country of Origin : Pune

...more

Tube Drilling Machine

With the RBV12 E we offer a low cost machine for incidental use. In contrast to the RBV12 this machine is provided with one drilling unit. Basic equipment supplied: • 1 piece locking sleeves SK40 ø16 mm • 1 piece special rotary grinder ø 12.15 mm (otherwise like RBV12)

...more

Trumpf Laser Machine

5,000,000 Per UNIT

Weight : 11500 kg

Sheet Notching Machine

600,000 Per UNIT

Automatic Grade : Semi-Automatic

Roll Forming Machine for Sandwich Panel

1 Pack(s) (MOQ)

We are offering roll forming machine for sandwich panel. Pm is a company highly specialized in sheet metal processing machinery and in particular roll forming lines, automatic punching and bending lines, transfer lines etc. And our machines are characterised by excellent manufacturing quality, sophisticated engineering, modularity, flexibility and productivity. our line of production has a great range of products like: - continuous and discontinuous lines for polyurethane roof and wall sandwich panels, cold rooms, etc - sectional door panels - trapezoidal, fretted and roof tile profiles, - deck profiles, - c + z purling profiles, - coil punching lines - seamed and welded tubes, - aluminium welded window spacers profiles, - punched welded and seamed tubes for burners, - automatic and semiautomatic roll forming lines for air ducts, - fire proof door profiles, - armoured doors profiles, - universal door profiles, - scaffolding systems profiles, - fans, - lightning profiles, - venetian type blinds, - false ceiling profiles, - suspended ceiling profiles, - partition panels for offices - gypsum wall profiles, - profiles for the automobile industry, - aluminium rolling shutters, - shutter boxes, - security rolls, - interior and exterior design profiles, - flexible lines for panels for freezers - electric appliances profiles, - profiles for the furniture industry - light – medium – heavy duty shelving systems and numerous other types of applications. in case you have a new project regarding sheet metal processing lines we are at you disposal. roll forming line for sandwich panel

Application : furniture industry light medium,heavy duty shelving systems and numerous other types of application

Condition : Good

Country of Origin : Pune

...more

Roll Forming Machine

1 Piece(s) (MOQ)

We are offering Roll Forming Machine to customers. It has the capability of forming 1 to 8 different profiles with a rugged construction and high precision. Our Roll Forming Machine is equipped with needle-type bearings, heavy chassis plate, hardened case, ground roll shafts, and arc welded steel stands. Furthermore, Roll Forming Machine is high on performance and very durable. We have come up as a prominent Supplier of Roll Forming Machine for different sheet Metal Products from Europe. All you have to do is that you have to give us the drawing and we will offer you the perfect solution for the same. We have the proficiency of dealing in bulk orders of Roll Forming Machine as well so don’t worry about the quantity as and when you place the order! We offer lines for : C - U - Z - Sigma Profiles Guardrails and road signs Guides for gates and doors Gypsum wall profiles Heavy duty shelving profiles Light duty shelving profiles Profiles electrical installations Profiles for air conditioning Profiles for doors and windows Profiles for fireproof doors Profiles for fixing systems Profiles for gratings Profiles for wooden furniture Special welded tubes Trapezoidal and corrugated sheets Tubes and elbows for gutters

Condition : Good

Country of Origin : Pune

...more

rounding machines

1 Piece(s) (MOQ)

We can supply the Roll Bending Machine from our principle Jouanel France Model RPL 2050 And also different models 2050-30EE RPL-2050- 40EE RPL2550-20EE Useful length (mm) 2 050 2 050 2 050 2 050 2 050 2 050 2 050 2 050 2 050 2 050 2 050 2 550 Roll bending capacity steel S235JR (mm) 0,8 0,8 1,2 1,2 1,2 2 2 2 3 3 4 2 �¸ rolls (mm) * 75 75 95 95 95 120 120 120 135 135 160 135 Drive operation �© M E M E EE M E EE E EE EE EE Power (kW) - 0,75 - 1,1 1,1 - 1,5 1,5 2,2 2,2 3 2,2 Working dimensions (mm) 2 520 2 570 2 650 3520 3550 3520 3520 3550 3520 720 720 850 850 950 850 800 900 850 1 100 1100 1200 1200 1200 1200 1200 1200 1200 3600 4020 1100 850 1200 1200 Weight (Kg) 720 750 1 650 1 770 1 850 1 740 1 770 1 850 2 020 2 055 2 500 2 300 Bending rolls machines type RPL version 2 and 2,5 meters 0

Material : High Grade Raw Material

Country of Origin : Pune

...more

Robot Bending Machine

1 Piece(s) (MOQ)

Robot Bending Machine, in which we deal, is loaded with an array of benefits that takes the value of the machine to heights. The machine is acquired from credible manufacturer, who work in accordance with the standards. We are emerging as the promising Supplier of Robot Bending Machine in Pune, Maharashtra. We work in an orderly manner to fulfill the orders for it within the stipulated timeframe.

Condition : Good

Type : Cnc`

Power : Ecletric

...more

PUNCHING UNITS - BS

1 Piece (MOQ)

BS activity started with the production of punching units. The units represent the most easy, economic and flexible solution to solve punching needs of flat and profiled sheet. BS manufactures different kind of punching units (punches and dies) offering ready solutions for the most common operations required.

Model Number : Punching Unit BS

Brand Name : BS S.a.s.

Place of Origin : Pune

Feature : The units represent the most easy, economic and flexible solution to solve punching needs of flat and profiled sheet.

Condition : Good

...more

Punching Machine

1 Piece(s) (MOQ)

Economical precision stamping machines, nibbling and transforming in one heavy-duty-machine � with the new punching machine MULTIPUNCH 1250 x 2000 CNC Z completes Boschert his delivery and performance program within the range of punching machines. Accordingly the wish of many customers and higher market requirement indeed the complete treatment of metal sheets in only one working off cycle, has been a new tooling system developed which consists of 8 stations for the admission of tooling system Trumpf. With it and included stepless indexable toolings are totally 64 toolings available and this might be more than enough for most of the sheet metal working. In addition is it possible to pre-adjust toolings for different sheets or for partial sheets by what the reequip expenditure will be to zero in case of instance of repetition. With the experience of more than 3000 delivered punching machines all over the world and the supplement of the new tool changer represent the Multipunch 1250 x 2500 CNC Z an universal and flexible punching machine for overcoming the different functions of sheet metal forming: accuracy punching, nibbling, forming. The size of the sheet panels can have the dimension of 1250 x 2500mm and depending on the material for 4 mm stainless steel 6 mm mild steel or 8 mm aluminium. Due to the stepless adjustment of the clamps may the sheet panels or pre-cut parts of all sizes be clamped, fixed and carried at discretion. An additional repositioning with two sheet hold down allows the complete working off the border so that at optimal nesting respectively utilisation of the sheet does not become waste. The combination of simple and rapid sheet-metal part handling as well as the split second changing of the tooling reduces the non-productive downtime to a minimum and conduct per time unit / shift to longer machine useful life. The tool changer can have all relevant punching, nibbling and forming tool system Trumpf as well as the other Boschert punchin

Type : CNC

Condition : Good

Dimension (LxWxH) : 1250 x 2500mm

Material : 4 mm stainless steel 6 mm mild steel or 8 mm aluminium.

Country of Origin : Pune

...more

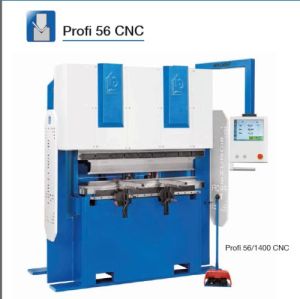

Profi 56 CNC - Boschert

Features : - Large touchscreen Hand drawing TouchProfile function USB port for memory sticks 4 axes control (Y1-Y2-X-R) TouchProfile 2D graphic part Efficient, economical folding, bending and pressing in the workshop and on the Production floor As simple as possible, providing as much as you need, plus various options for individual The electrically driven and thus freely positionable rear stop system as well as the control unit. The result is a compact, high-performance press in yet another performance dimension. Customization - according to this principle, Boschert GmbH & Co. KG, the specialist for The PROFI hydraulic die-bending and folding press series to include the new PROFI 56 CNC Model. A press system for universal application was developed based on the oft-proven design. On a solid welded frame, with a folding beam guided by four sophisticated linear components. As well as two hydraulic pressure cylinders with 28 tons of pressure each. The practical Combination consists of four linear guides at right and left for the folding beam, two separately, Controllable hydraulic cylinders for the raising/lowering operation of the upper tool, two Measuring systems per cylinder, two versions of tool holders for different stamping systems, The standard PROFI 56 CNC die-bending press is available in the versions PROFI 56/1000 CNC and PROFI 56/2200 CNC with working lengths of 1,000 and 2,200 mm. The clearance Between the stands is 890 and 2,100 mm respectively. The stroke is 200 mm and the Clearance between the folding beams is 310 mm, so that tall tools can also be used, thanks to The maximum installation height of 325 mm. The worktable is 2 x 270 mm and accepts Correspondingly wide tool systems for universal use as a press system for folding, die-bending Or press work of all types. The machine has a stable, rigid design for reproducibly accurate Individual and series production, and is equipped with sophisticated machine components. Furthermore, each cylinder has its own hydraulic drive and is monitored by its own measuring System. The control unit continuously compares the current positions and adjusts these as Required. It was designed as a master-slave control system, so that consistent pressing Accuracy is ensured across the entire working width. The control system permits easy entry of the folding length and the bending angle. A maximum Of 250 different work programs (folding lengths and bending angles) can be configured and Called up at any time. Additional parameters such as tool data, material thicknesses and Material data can be entered via „Teach-in“. The entry of the actually required angle is used in process During folding/pressing to correct the angle in the mold, and the reproduction Accuracy of the press stroke is specified as +/- 0.02 mm. Thus every part is a „good part“. The Folding and pressing work can be carried out semi-automatically and therefore with optimal Timing thanks to the electrically adjustable and controllable rear stop, which is equipped with? Two stop bars that can be laterally and vertically adjusted. The working speed is 8 to 10 mm/s And the return speed is 40 mm/s. This facilitates short work cycles. Available accessories and options include various tool systems, tools and metal support arms With T-groove strips. The user thus receives a cost-effective complete solution ready for Operation, which consists of the machine, tools and service in the renowned Boschert quality.

...more

Profi 28 CNC - Boschert

The BOSCHERT Profi 28 NC and Profi 28 CNC are precision hydraulic press brakes. The extremely compact and robust structure of these machines and the twin guides guarantee ram repeatability of 0.02mm. The Profi are designed to manufacture small parts and perfectly compliment your existing larger machines. By forming small parts on the Profi and larger parts your existing machines, plant productivity is greatly improved. Standard tooling is Amada style, with other systems available on request. Material stops are adjustable vertically and horizontally and have stop fingers with two faces each. With a maximum bending force of 28 tons, typical work could include parts up to 300mm long and 10mm thick.

Type : Profi 28 NC / CNC

...more

Plate Bending Machine

1 Piece(s) (MOQ)

Our Plate Bending Machine comes in different capacities ranging from 1.5 meters to 3 meters and thickness ranging from 3mm to 100 mm. It comes with 3 and 4 rolls and single and double pinch. Further, Plate Bending Machine is equipped with independent motors and gearboxes, two powerful hydraulic cylinders, and a hydraulically operated drop end bearing. Plate Bending Machine has a sturdy construction, user-friendly operation, and low operational cost, because of which it is preferred by various manufacturers. Applications : Double Pinch Three Rolls plate bending machines are considered as the ideal solution to roll plates into cylinders with a minimum investment. They are known to be the best solution for rolling cones other than cylinders. How It Works : The pre-bending is made by positing the plate edge between the pinch rolls and by moving the bending roll with a pressing operation. After the first edge is pre-bent it is not necessary to remove it from the rolls as the second pre-bending can be made immediately following the same procedure used for the first edge. As soon as the two plate edges have been formed, it is possible to proceed with the rolling to distribute the deformation along the plate developed length. He Biko Three Rolls Technology : Ultra-Wide drop end : minimises the top roll transverse movement guaranteeing superior quality of the rolled product that will not be affected by excessive frame extension and torsion. Fully Hydraulic Movements : to provide maximum bending power without loss of energy and overloads on mechanicalcomponents; Hydraulic Circuit made with rigid steel pipes guarantee reliability and positioning precision. High Capacity roller and spherical bearings : provide friction-free rotational movement of rolls and reduce maintenance needs. Swing Arms friction is eliminated by areliable lubrication system guaranteeing long term reliability. Rolls Made of Certified Quality steel : with large shafts diameter minimise the deflection under load and damage on the surface. Upon request they can be induction hardened to over 50 HRC and surface polished. Direct Drive for rolls rotation : for high torque fast rolling power and maximum efficiency trough planetary gearboxes. All three rolls are driven independently. Automatic Rolls Peripheral Speed Compensation : to guarantee optimum distribution of the torque without need of manual adjustment. Clamping Pressure Control : for optimum automatic setting of the pinch roll position according to the different plate sizes. Mobile control console : positioned at the front of the machine is the ideal solution to keep under control the rolling process from the best point of view. Safety Barrier : for immediate emergency stop of machines movement when the operator is near hazardous area. Accessories On Demand : Top Support : It avoids the rolling of overlapped plate edges. It helps the positioning of the plate edges for tack welding. Dimensions : 3mt x 3Ton Digital Readouts : Two (2) Electronic digital displays mounted on the operator’s control indicate the positions of the left and right bending rolls. (X & Y axes.)Cone Rolling Package : Hydraulic tilting of the bending rolls. Hydraulic tilting of the bottom pinch roll. Cone stopper (friction or wheel typ. Accessories Included with the Machine : Prevents excessive roll wear especially when rolling cones or when rolling Stainless steel, flame out steel and other hard materials. Prevents scratching of the roll surfaces. CE Certification : For machine safety.Main Technical Data : Maximum Rolling Capacity (Cold) : mm. 20 Maximum Pre-bending Capacity (Cold) : mm. 15 Cone capacity by continuous rolling : 60% of prebending thickness Cone capacity by pressing : 100% of prebending thickness For further bending capacities, please refer to the detailed Capacity Chart. Rolls face length : mm. 3.050 Number of rolls : Three Diameter of Top Roll mm. 350 Diameter of Bottom Rolls mm. 320 Powered Driving Rolls : Three Drive System : Directly splined on the roll shaft Surface Speed Compensation Automatic Rolling speed : 5Mt./min. Rolls movements adjustment Hydraulic Installed power (Energy Saving Technology) ES HP 25 Power Supply 380 Volts, 3 Phase, 50 Cycle

Condition : Good

Usage : Double Pinch Three Rolls plate bending machines are considered as the ideal solution to roll plates into cylinders with a minimum investment.Plate Bending Machine

Country of Origin : Pune

...more

CNC Plasma Duct Cutting Machine

Owing to our rich industry experience, we are reckoned among the preeminent Suppliers of Plasma Duct Cutting Machines. The Plasma Duct Cutting Machines we make available are manufactured using quality-tested components and advanced technology. Strict quality-tests ensure that only defect-free Plasma Duct Cutting Machines reach the buyers. Bulk orders of the Machines are processed by us as per the specific requirements of the buyers.

Country of Origin : Pune

...more

Pittsburgh Roll Forming Machine

1 Piece(s) (MOQ)

We are amidst the most sought after Suppliers of the excellent and highly durable Pittsburgh Roll Forming Machine. We have associations with the leading manufacturers and vendors in this domain and owing to this, we are capable of fulfilling the demands of the clients. We make deliveries of the same in set time span. More About Pittsburgh Roll Forming Machine :Principally used for joining sheet metal at right angles on straight runs, the machine comes complete with pitsburgh rolls. Auxilliary shafts are fitted as standard, onto which double seam rolls can be fixed. When the flanging attachment is used with the machine this makes possible the forming of round bends. The machine is capable of forming a maximum of 1mm(20g) Power flanging specifications Max. sheet thickness : - 1.6mm In mild sheet : (16g) Min. Corner Radius : 100mm(4 in) Forming speed : 3m/min. Specifications: Length : 1455mm Width : 615mm Height : 1000mm Weight : approx. 250kg. Pittsburgh Material thickness : 0.8-1.5mm(22-16g) Material used : 35mm Pocket depth : 13mm(1/2 in) Auxiliary forming rolls Double seam close : Material thickness : 0.8-1.2mm(22-18g) Material used : 32mm(1M in) Seam width : 13mm(1/2 in) Drive Cleat : Material Thickness : 0.5-1mm(26-20g) Material Width : 54mm(2s in) Cleat Width : 29mm(1s in) Plain Seam : Material Thickness : 0.7-1mm(22-20g) Material Used : 11mm(7/16in) Seam Width : 10mm (3/8 in) Right Angle Flange : Material Thickness : 1-1.2mm(20-18g) Material Used : 11mm(7/16 in) Flange Height : 11mm (7/16 in) Standing Seam : Material Thickness : 0.7-1.2 mm (22-18g) Material Used : 54mm(2s in) Seam Height : 19mm (¾ in)

Condition : Good

Country of Origin : Pune

...more

Notching Machine Lb12/4

1 Piece(s) (MOQ)

We are offering notching machine lb124. The lb 12pn model permits notching with a fixed angle of 90°. It guarantees clean cuts in all sheet metal thicknesses and high repetitive accuracy of the notches. It is also ideally surted for cuts on one side. Because of the special design of lb 12pn the blades achieve an extraordinarily high life even when notching a special steel. further characteristics of the lb 12pn: - automatic cutting gap adjustment - maintenance free lubrication system - integrated overload protection - extremely quiet except steel and stainless steel, the notching machines of boschert cut also plastic and grid material:

Condition : Good

Country of Origin : Pune

...more

NC Press Brake Machine

1 Piece(s) (MOQ)

We are ranked amidst the celebrated Suppliers of the highly durable NC Press Brake Machine. We have rich industry associations with the foremost manufacturers in this domain. We are capable of delivering the best in class Brake Machine to the customers. We make sure that the range is as per the International Standards. More About NC Press Brake Machine:Known for their dependable hydraulic systems, range of press brakes are all top of the line. With a high parallel accuracy, extra-wide guideways, and a rigid construction throughout these machines really offer exceptional results. The robust press brakes from Fintek always live up to customer expectations, by delivering very dependable, consistent, and excellent results. With a high accuracy depth of bending and oversized hydraulic oil tank for high performance pumping, these machines are all extremely high performance. No matter the size or capacity they can custom make machinery that exactly meets their customers' requirements. Whether it is a large manual type, or automatic press brake can cater to all desires. Quality Features that Assure Accuracy, Productivity & Trouble-free Operations Rigid Construction Thru-Out The entire machine frame is manufactured from high-tension steel plate, stress relieved for deformation free year after year the frame is rigidly welded and bolted to create a robust machine structure. Extra Wide Guide-Way The extra wide guide way design provides added smoothness and stability for guide block movement, reciting high accuracy as des red. High Parallel Accuracy The parallel mechanism is a mechanical structure, providing forced synchronized motions for the top and bottom die. This assures high parallelism accuracy between both dies at any position of stroke movement. Oversized Hydraulic Oil Tank High Performance Pump The big tank capacity increases oil flow smoothness and better oil cooling efficiency.The high performance pump features low noise running and stable oil flow. Accurate Depth Of Bending High accuracy depth positioning is controlled by mechanical stops inside cylinder assuring accurate angle of bending at all times. Dependable Hydraulic System The hydraulic system includes high quality solenoid valves and two powerful cylinders, featuring powerful force output and stable motions. Two-step downward speed design. Fast speed for approaching work piece and low speed for bending operation, which greatly shortens machining time. Working pressure is easy to set by simply turning a variable regulator with overload protection to provide a proper pressure.

Condition : Good

...more

Motorised Bending Machine

Color : Grey

Voltage : 110V

Condition : New

Operating Type : Automatic

Warranty : 1 Year

...more

Manual Tube Punching Machine

1 Piece(s) (MOQ)

Manual Hydraulic punching machine for tubes and profiles P80-M. - Manual positioning of holes according to raster guide - Manual feeding and stepping - driven by hand - positioning through raster guide - This model is suitable for short-run production

Brand Name : BS S.a.s.

Condition : Good

Country of Origin : Pune

...more

Manual Punching Machine

1 Piece(s) (MOQ)

We are a trusted Supplier of Manual Punching Machine from Maharashtra, India. We are engaged in offering all ECCO line machines, which are equipped with Trumpf Tooling system and 28 t punching pressure that can be 40 t on special request. Our Punching Machine can be obtained at nominal prices. Order retail or bulk, punctual deliveries are confirmed!All models are equipped with : Constant punching pressure Maintenance-free hydraulic drive One stripper holder and a plate Two different stroke length The ECCO Line earns money with : Small and medium series Single pieces and prototypes Tooling system : The worldwide approved Trumpf tooling system is used on the ECCO Line (other systems on request, e.g. Amada, Rainer, XX28) The tool is put directly into the tool holder without an intermediate case. Through the large propagation of the Trumpf tooling, the machine is virtually always ready for operation 7 seconds. The largest tool diameter is 105 mm (4"). Besides a wide range of standard tools, it is possible to manufacture arbitrary tool within the range of 105 mm diameter The metal loss from sharpening will be compensated through changes of the punch stroke length Exact alignment of cutting tools with riding clamping ensures long tool life It also enables the use of angled Whisper-Tools which can achieve a noise reduction of up to 50% Technical Specifications : Working Area : EL 300 x 500 370 x 700 EL 500 x 1000 570 x 1200 EL 750 x 1500 820 x 1700 Performance : Max. sheet thickness 12,7 mm Max. hydraulic punching pressure 280 kN / 400 kN Speeds : Max. stroke rate 100 strokes / min Tooling : Trumpf ® style tools Max. punching diameter Ø 105 mm or any shape fitting within 105 mm / 74 mm Optional 92 x 92 mm Tool change time 15 sec. manual Accuracy of Punching : With standard measuring scales + - 0,2 mm With digital readout + - 0,1 mm Space requirement and weights : EL 300 1520 x 940 x 1540 mm weight 1800 kg EL 500 2400 x 1580 x 1540 mm weight 2500 kg EL 750 3400 x 1580 x 1600 mm weight 3400 kg Electrical Values 28 / 40 T. Electrical connection value 5 / 8 kVA Hydraulic motor 4,0 / 5,5 kW Required fuse 3 x 16 A / 3 x 16 A Hydraulic oil 50 / 115 liter

Condition : Good

Country of Origin : Pune

...moreOpening Hours