Ceramic Foam Filters

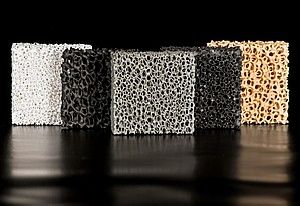

Dominant activity of the LANIK s.r.o. company is represented by manufacture and sale of the ceramic foam filters used under the trade name VUKOPOR® mainly in the foundry industry and in the primary aluminium production. Thanks to the mechanism of creation of the “filter cake” on the inlet filter side and thanks to depth filtration inside the ceramic matrix they represent the effective instrument enabling to reach metallurgical purity of the molten metal during the process of casting. The ceramic foam filters VUKOPOR® also calm mould filling, thus preventing creation of new inclusions and undesirable defects in the casting. The calming effect on mould filling is conditioned by conversion of turbulent liquid metal flow upstream the filter into the laminar flow downstream the filter. These VUKOPOR® filter features are conditioned by the open 3D structure of the ceramic matrix created by the system of mutually interconnected cells. The filters are characterized by a very good thermal conductivity, stability and resistance to sudden temperature changes. By applying ceramic foam filters, a higher quality of castings at lower costs for their manufacture can be reached in general: Increase of quality of castings: better surface of the castings improved mechanical features of the castings better dimensional and shape accuracy of the castings Lower costs: reduced rejection rate lower costs for machining of the castings

...more

Ceramic Foam Filter

Thanks to the mechanism of creation of the “filter cake” on the inlet filter side and thanks to depth filtration inside the ceramic matrix they represent the effective instrument enabling to reach metallurgical purity of the molten metal during the process of casting. The ceramic foam filters VUKOPOR® also calm mould filling, thus preventing creation of new inclusions and undesirable defects in the casting. The calming effect on mould filling is conditioned by conversion of turbulent liquid metal flow upstream the filter into the laminar flow downstream the filter.

...more

ceramic cups

Ceramic pouring and filtering cups are used for investment casting technology. They are made of high-quality ceramic material and pressed at high pressure. They are fit for casting ferrous as well as non-ferrous metals, withstand the most strenuous conditions within superalloys casting for aircraft industry. Ceramic cups provide these benefits: reduced castings contamination by ceramics of a ceramic shell significantly reduced wax consumption from gating system production reinforced shells enabling handling within the production cycles possibility to accommodate ceramic filters of standard dimensions

...more

Ceramic Cores

Ceramic cores MP are designed for castings made by the lost wax method. They are made by the technology of medium pressure injection moulding (mixture of ceramic and wax). This technology is quite tool friendly, means there are not so high requirements for the die and also that the tool has higher life time (compare to other technologies). By our technology cores with thin (0,35 mm) as well as thick (>100 mm) cross sections can be easily produced.

...moreBe first to Rate

Rate ThisOpening Hours