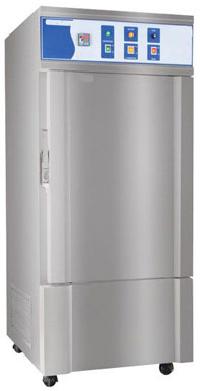

Thermal Shock Test Chamber

Get Price Quote

1 Piece (MOQ)

Kaizen Airtech Solution being a leading manufacturer in Thermal shock test chamber provides a controlled environment for testing products. Chamber available size form small bench top boxes to big computer controlled walk-in chamber. Thermal Shock Testing chamber Systems are designed for compatibility with your choice of Air heating system. This provides you with the flexibility to use your existing heating chamber. The thermal testing chamber is used to test the bearing extent of the material structures and composite material in an instant and continuous high temperature and extremely low-temperature environment. that is in the shortest time to test its thermal expansion and contraction caused by the chemical change or physical harm. Each model is manufactured to standard designs, but may be custom engineered to meet a wide range of stringent test requirements. Optimal test environments require thermal chambers configured for device size, temperature range, transition speed and device access.Key Benefits: Energy Efficient Superior airflow uniformity Easy Operation Extremely stable and uniform Environment Features: Work spaces size range from 300 to 3,300 litres to accommodate many product sizes HEPA Filter with 99.999% efficiency against 0.3µm particles, 99.995% filter efficiency for MPPS at 0.1µm improves safety The interior chamber of the unit is constructed of a durable, corrosion resistant 304 stainless steel. Low watt density heaters are used that also contribute to the unit’s longer life. Microcomputer base temperature controller which is automatic control high low temperature cycling. Both remain and change time can be adjustable, it has various safety precautions and device with several record methods Unique design of thermal barrier for better energy efficiency, Machine filled PUF insulation to eliminate void pockets, puff insulation density 40kg/ meter^3 Customize chamber airflow can be factory configured from the standard horizontal flow to a vertical flow. When the harmful task condition like short-circuit, leakage; compressor with over-pressure, over-load, oil pressure, water-break, over temperature the screen will automatic display the fault cause and provide exclusion method. Heating and cooling system ensures accurate test results for your product during environmental testing. PTC works for both heating and cooling.All equipment is fully automatic, and all process are precisely controlled with P.L.C.’S. Thermal Shock Tester is divided into three sections: the high temperature chamber, the low temperature chamber and the testing chamber When the input voltage is unstable, due to it has the stop device that the remove time of high-low temperature shock structure within 10s.5-minute recovery time for this product.

Thermal Shock Chamber SHOCK SERIES

Get Price Quote

Best Deals from Thermal Shock Chamber

Thermal Shock Chamber

Get Price Quote

thermal shock chambers

780,000 Per Unit

Thermal Shock Chamber

Get Price Quote

Thermal Shock Chamber, High Low Test Chamber, Vibration Tester Chamber

Thermal Shock Test Chamber

Get Price Quote

Thermal Shock Test Chamber, HIGH LOW TEMPERATURE CHAMBER