Ultrasonic Pulse Velocity Testing

Get Price Quote

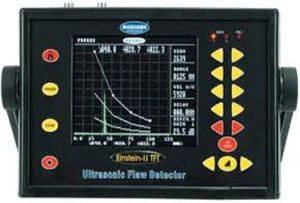

We offer Ultrasonic Pulse Velocity Testing services according to IS – 13311 (Part 1): 1992. Located in Maharashtra (India), our services are highly in demand. This method is used for testing ultrasonic pulses that are transmitted through the concrete. In solids, the particles can oscillate along the direction of sound propagation as longitudinal waves, or the oscillations can be perpendicular to the direction of sound waves as transverse waves. At surfaces and interfaces, various types of elliptical or complex vibrations of the particles occur. Our instrument is dependent on Dynamic Young’s Modulus, density, and Poisson’s ratio of the material. A complex system of stress waves is developed which includes longitudinal (Compressional), shear (transverse) and surface (releigh) waves. Piezoelectric transducers are designed to generate longitudinal and transverse (shear) waves. The active element of most acoustic transducers is piezoelectric ceramic. These transducers convert electrical signals into mechanical vibrations (transmit mode) and mechanical vibrations into electrical signals (receive mode). The travel time is measured with an accuracy of +- 0.1 microseconds. Transducers with natural frequencies between 20 kHz and 200 kHz are available, but 50 kHz to 150 kHz transducers are common.

Ultrasonic Testing Services

Get Price Quote

Ultrasonic testing (ut) in most common ut applications, very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 mhz, and occasionally up to 50 mhz, are transmitted into materials to detect internal flaws or to characterize materials. It is used in many industries including steel and aluminium,construction,metallurgy,manufacturing, aerospace, automotive &other transportation sectors. In service ultrasonic testing for preventive maintenance is used for detecting impending failure of rail road rolling stock axles, press columns, earth-moving equipment, mill rolls, mining equipment and other machines and components. The flaws to be detected include voids, cracks, inclusions, pipe, laminations, bursts and flakes. They may be inherent in the raw materials, may result from fabrication and heat treatment, or may occur in service from fatigue, corrosion or other causes. Ultrasonic testing can also be used to measure thickness of metal sections during manufacturing and maintenance inspections

Looking for Ultrasonic Testing Services Providers