Ultrasonic Testing Services

Get Price Quote

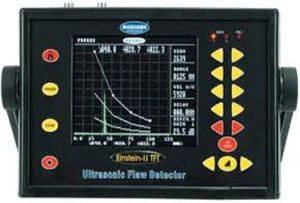

Ultrasonic Testing is family of Non Destructive Testing Techniques best on the propagation of ultrasonic waves in the object or material tested. There are two methods of receiving the ultrasound waveform, reflection and attenuation. In reflection (or pulse-echo) mode, the transducer performs both the sending and the receiving of the pulsed waves as the "sound" is reflected back to the device. Reflected ultrasound comes from an interface, such as the back wall of the object or from an imperfection within the object. The diagnostic machine displays these results in the form of a signal with an amplitude representing the intensity of the reflection and the distance, representing the arrival time of the reflection.

Ultrasonic Testing Services

Get Price Quote

• ultrasonic testing • in ultrasonic testing (ut), the very short frequency ultrasonic pulse-waves with frequencies ranging from 0.1-15 mhz and occasionally up to 50 mhz are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement, which tests the thickness of the test object where other side is not accessible like pipes and pipe corrosion. • ultrasonic testing is often performed on steel, other metals and alloys, though it can also be used on concrete, wood and composites, albeit with less resolution. It is a form of non-destructive testing used in many industries including aerospace, automotive and other transportation sectors. • • it works on the principle of high frequency sound waves travelling in a solid medium and the waves and its back echo to give scan results. Even jobs in which the other side is not accessible (as needed in radiography testing) the ultrasonic testing can be done .there is recording system in the digital ultrasonic machines where complete scanning can be recorded. The ut machines are operated by chargeable batteries and therefore can be taken easily at site even at heights.

Looking for Ultrasonic Testing Services Providers

Ultrasonic Testing Services

Get Price Quote

Ultrasonic testing (ut) in most common ut applications, very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 mhz, and occasionally up to 50 mhz, are transmitted into materials to detect internal flaws or to characterize materials. It is used in many industries including steel and aluminium,construction,metallurgy,manufacturing, aerospace, automotive &other transportation sectors. In service ultrasonic testing for preventive maintenance is used for detecting impending failure of rail road rolling stock axles, press columns, earth-moving equipment, mill rolls, mining equipment and other machines and components. The flaws to be detected include voids, cracks, inclusions, pipe, laminations, bursts and flakes. They may be inherent in the raw materials, may result from fabrication and heat treatment, or may occur in service from fatigue, corrosion or other causes. Ultrasonic testing can also be used to measure thickness of metal sections during manufacturing and maintenance inspections

UT software

Get Price Quote

Development of UT software for the automated inspection of pipes,, wheels or any large structures.

Ultrasonic Pulse Velocity Testing

Get Price Quote

We offer Ultrasonic Pulse Velocity Testing services according to IS – 13311 (Part 1): 1992. Located in Maharashtra (India), our services are highly in demand. This method is used for testing ultrasonic pulses that are transmitted through the concrete. In solids, the particles can oscillate along the direction of sound propagation as longitudinal waves, or the oscillations can be perpendicular to the direction of sound waves as transverse waves. At surfaces and interfaces, various types of elliptical or complex vibrations of the particles occur. Our instrument is dependent on Dynamic Young’s Modulus, density, and Poisson’s ratio of the material. A complex system of stress waves is developed which includes longitudinal (Compressional), shear (transverse) and surface (releigh) waves. Piezoelectric transducers are designed to generate longitudinal and transverse (shear) waves. The active element of most acoustic transducers is piezoelectric ceramic. These transducers convert electrical signals into mechanical vibrations (transmit mode) and mechanical vibrations into electrical signals (receive mode). The travel time is measured with an accuracy of +- 0.1 microseconds. Transducers with natural frequencies between 20 kHz and 200 kHz are available, but 50 kHz to 150 kHz transducers are common.

Ultrasonic Testing Services

Get Price Quote

Ultrasonic Testing Services, dye penetrant testing, magnetic particle testing

ultrasonic testing service

Get Price Quote

ultrasonic testing service, magnetic particle testing, radiography Testing

Ultrasonic Testing Services

Get Price Quote

Ultrasonic Testing Services, dye penetrant testing services

Ultrasonic Testing Welding Inspection

Get Price Quote

Ultrasonic Testing Welding Inspection, Third Party Pump Inspection

Ultrasonic Pulse Velocity Testing services

Get Price Quote

Ultrasonic Pulse Velocity Testing services, Fiber Wrapping Services

Ultrasonic Testing Training

Get Price Quote

Ultrasonic Testing Training

Ultrasonic Test Service

Get Price Quote

Ultrasonic Test Service, Spark Test, Portable Hardness Test