Waste Heat Recovery Boilers

WHRBs offer efficient, cost-effective and reliable steam generation while recovering excess heat from industrial processes. Uttamenergy is a Licensee of ERK Eckrohrkessel gmb Hand offers its designs for WHRBs. Boiler Operate on a wide variety of Heat sources includes: Sponge Iron (DRI Plant) Coke oven Plant Gas Engine Exhaust(GT) Desel Engine Exhaust(DE) Cement Plant Heat Exhaust Sponge Iron Kiln Waste Heat Recovery Boilers Kiln Capacity : 50 TPD, 100TPD, 350 TPD, 500 TPD etc. Steam Pressure : 45 Kg/cm2(g) to 110 Kg/cm2(g) Steam Temperature : Up to 540°C Coke Oven Waste Heat Recovery Boilers Capacity : up T0 80 TPH Steam Pressure : 45 Kg/cm²(g) to 88 Kg/cm²(g) Steam Temperature : Up to 545°C

...more

waste heat boilers

Single Drum, Natural Circulation: Bottom Top Supported Design, Horizontal Vertical Self-cleaning Design for greater operational comfort, Design takes care of high dust concentration in gases, Gas tight Water Wall Furnace, Machine-welded membrane panel, Membrane panels provide gas tight enclosure for better efficiency of boiler & minimum refractory.

...more

travelling grate boiler

In Travelling Grate boilers, the grate is a moving part. Above the grate the fuel is spread either by mechanical spreader (for Coal) and Pneumatic spreader (Bagasse & Biomass fuels). The lighter portion of the fuel burns in suspension and the heavier portion burns in the moving grate bed. Combustion air is passed under the grate which moves up towards the fuel and Over fire air is used to improve the suspended combustion. At the end of the grate the ash residues are collected in the front ash hopper. Our traveling Grate Boilers offer high efficiency through a proven design that ensures complete combustion through high turbulence and thorough mixing of volatile gasses. Continuous ash discharge provides for higher productivity and lower downtime.

...more

Oil And Gas Fired Boilers

Our oil and gas fired boilers are Package/water tube boiler with single-drum/ bi-drum configurations. They cater to process and power applications with fuels like biogas, natural gas, blast furnace gas, coke oven gas, hydrogen gas, furnace oil, low sulphur heavy stack oil (LSHS), naphtha, light diesel oil (LDO) and high speed diesel (HSD). Uttamenergy is a Licensee of ERK Eckrohrkessel GmbH and uses its designs for oil and gas fired boilers. For More Information, Merit More than 3900 references through ERK Eckrohrkessel Corner tube system with self-supporting frame. Quick Start up time. Faster response to Load variations. High steam purity is achieved. Compact design to fit space requirements. Modular construction makes simple erection with few site welds

Capacity : 1 to 220 TPH

Pressure : Up to 140 kg/cm2(g)

Application : Power & Process

...more

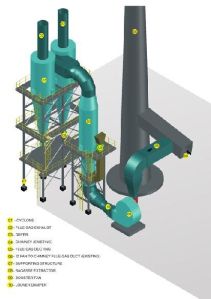

Bagasse Dryers

The hot flue gas from the boiler are made to pass through the dryer under forced draft. The wet mill bagasse is fed through a rotary air lock feeder at the bottom of the dryer. It is then carried upward in a co-current mode with the hot flue gas at a calculated velocity based on Average Particle Retention Time (APRT). During this process, bagasse moisture evaporates and the dried bagasse is subsequently separated through a high efficiency cyclone separator. The dried bagasse is continuously evacuated from the bottom of the cyclone(s) through air-lock valves for onward feeding to the boiler. Adequate automation including differential pressure monitoring is provided. Advantages 1.Moisture reduction up to 37% & below. 2.It increases boiler efficiency by minimum 5%. 3.Differential pressure control across drier to avoid bagasse chock up. 4.Stainless steel constructed parts at critical locations. 5.It reduces excess air requirement, which in turn reduces power consumption of boiler fans. 6.It optimizes bagasse burning and improves clean emission. 7.It saves bagasse due to improvement in boiler efficiency or alternatively more power can be exported to grid. 8.Dry bagasse ensures a faster response to load and maintains boiler pressure/temperature stable. 9.It generates high temperature inside boiler furnace and improves efficiency. 10.Due to complete combustion of fuel, wear and tear of boiler parts reduces, thereby reducing maintenance cost. 11.VFD Controlled booster fan to cater moisture & particle size variation. 12.Improvement in the combustion performance resulting in better load response characteristics. 13.Typical surplus bagasse obtained from 90 TPH boiler will be 65 TPD approx.

...more

Bagasse Dryer

The hot flue gas from the boiler are made to pass through the dryer under forced draft. The wet mill bagasse is fed through a rotary air lock feeder at the bottom of the dryer. It is then carried upward in a co-current mode with the hot flue gas at a calculated velocity based on Average Particle Retention Time (APRT). During this process, bagasse moisture evaporates and the dried bagasse is subsequently separated through a high efficiency cyclone separator. The dried bagasse is continuously evacuated from the bottom of the cyclone(s) through air-lock valves for onward feeding to the boiler. Adequate automation including differential pressure monitoring is provided.

...more

Atmospheric Fluidized Bed Combustion Boilers

AFBC boilers offer efficient, cost-effective and reliable steam generation. The benefits include fuel flexibility, high efficiency, low emissions, and reduced capital and operating expenses. Our boilers are ideal for burning fuels containing high ash and high Sulphur content. Type of Combustor Air box Open Bottom Hopper Bubbling bed FEATURES Multi-fuel firing options. Optimum combustion with appropriate secondary air system. Machine welded membrane panel. Membrane panels provide gas tight enclosure for better efficiency of boiler & minimum refractory. In bed Evaporator design for better reliability and temperature control Under bed / Over Bed fuel feed system Studded in-bed coils for enhanced heat transfer & reduce erosion. 2-Stage / 3-Stage Super Heater with Inter-Stage Spray type De- Superheater Bottom / Top Supported Design

Capacity : 10 to 200 TPH

Pressure : Up to 140 kg/cm2(g)

Application : Power & Process

...moreBe first to Rate

Rate ThisOpening Hours