Toughened Glass

we offer Toughened Glass. toughened glass is produced by heating annealed glass in a furnace to approximately 700degC and then rapidly blowing cool air onto both surfaces. This rapid cooling process is the key element in the physical changes in annealed glass that creates toughened glass. Toughened glass cannot be drilled or edge worked in any manner. A slight distortion or bowing may occur after toughening but is largely controllable. It will vary with substance, tint, surface treatment, size and shape of the glass. Ceramic painted, sandblasted or reflective coated glass has a greater tendency to bow and special tolerances would be advised. Flatness will be measured when the glass is standing on edge with a straight edge placed along the full length of the panel and a wedge measurement taken at the centre position. Stamps are located in the ‘normal position’ at the bottom left hand corner or ‘special position’ to customer specification. Please state on your requirement order. Stamps available include GLAZING, AUTOMOTIVE and special sized stamps for louvres. Stamps can be custom made to customer’s name and specification. Please refer to Veeral Glass for more details. Where no stamp is requested, the customer may be required to provide a compliance letter or certificate if so requested by relevant authorities. It is always advisable to identify toughened glass by stamping. Tempered glass is a generic term for glass that is either toughened or heat strengthened. Clarification should be sought as to which type of tempering is required and whether either one meets relevant code requirements.

Brand Name : eTemp

...more

Reflective Glass

we offer Reflective Glass. Reflective glass absorbs and reflects a major proportion of the sun’s direct energy more effectively than tinted float glass. The mirror like appearance of reflective glass is achieved through the application of a metallic coating during or after glass manufacture There are two types of reflective glass available, pyrolytic and vacuum coated: Pyrolytic: - a coating is applied during glass manufacture. It is basically an economical reflective product. The coating is fused into the glass at 1200 degree C. The advantage of this product is its durability. It can be handled like a standard square of glass. It is ready to be cut, heat strengthened and toughened. This product is sometimes called a ‘hard coat’ reflective. Its coating is more durable than soft coat. The same cleaning procedures as for normal glass can be applied to Pyrolytic. It can be laminated to various required thicknesses as well. Vacuum coated glass: - involves the deposition of metal particles on the glass surface by a chain reaction in a vacuum vessel. It is often called a ‘soft coat’, because the coating is more susceptible to damage than a hard coat glass when glazed in monolithic form. Vacuum coated reflective glass products are generally better performers in terms of reducing heat gain than pyrolytic or hard coat products. Different coating combinations on clear and tinted glass or with combinations of tinted PVB interlayer in laminated glass, give an array of colour and performance features. These products can also be made up into insulated glass units with Low-E coatings for superior energy efficiency. Veeral Glass has available an extensive range of vacuum coated reflective glass products to suit most applications. The use of reflective glass represents a popular choice in commercial and domestic glazing today. They provide superior performance to standard glass products in terms of reflecting heat and reducing air conditioning loads.

...more

Laminated Glass

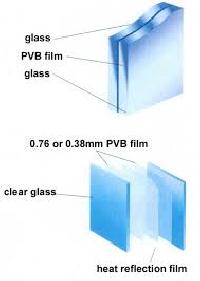

We are offering laminated glass is a safety glass made by laminating two or more sheets of equalunequal glass thicknesses with a flexible plastic interlayer or pvb (poly vinyl butyral). The glass and interlayer are bonded together by heat and pressure. Generally this interlayers are 0.38mm, 0.76mm, 1.14mm, and 1.52mm. Thick. The safety aspect of laminated glass is due to its pvb interlayer which prevents the glass from disintegrating if broken, the glass adhering to the interlayer depending on the severity of the impact. Laminated glass also acts as a barrier against penetration. Laminated glass is also available in tinted form. Tinted laminated glass simply uses a coloured interlayer between clear glass which also assists in reducing solar heat entry.

...more

Insulated Glass Units (dgus)

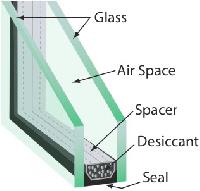

We are offering insulated glass units (dgus). Insulated glass units (igu�s) or double glazed units are a significantly more energy efficient glazing system than single glazed windows. It is estimated that up to 30% of heat entering the home and up to 50% of winter heat loss is a result from the use of single glazing. Igu�s consist of two or more panels of glass separated by airspace and aluminium or other type of spacer around the edges, sealed to the perimeter in controlled conditions. The spacer contains a desiccant (drying agent) which eliminates moisture vapour in the cavity. The combination of the two panels of glass and the trapped air is what makes igu�s a superior energy efficient method of glazing. The glazing system must be designed to drain out all water in the rebate and a void must exist under the unit so that moisture is not trapped against the edge of the glass. generally units should be glazed with a minimum 3mm clearance between the glass face to rebate a minimum 3 - 6mm clearance under the unit in the rebate (size of block) and a minimum 12mm cover or bite in the rebate. dry glazing of units is always recommended but if units are to be glazed or bedded into compounds or sealants it is imperative that compatible sealants are used or edge failure may result.

...more

Ceramic Fritted Glass

Ceramic fritted glass consists of a ceramic based paint screen printed onto clear, tinted, patterned or reflective glass (pyrolytic only). It can also be referred to as colour clad, ceramic fired, ceramic backed or even an opacified glass. Ceramic fritted glass has a major use in building cladding. Its main function is to match or contrast vision panels where an all glass facade is desired. The glass is heat strengthened or toughened which fuses the paint to the glass creating a permanent durable coating. The benefit of heat strengthening is apparent, where upon breakage, the glass tends to fragment into large pieces and stay intact in the opening or framework. The other main benefit of ceramic fritted products for spandrel applications is their greater durability in comparison with various other methods of spandrel glazing. If matching vision and spandrel panels, the general rule is that products with a visible light transmittance greater than 20% are difficult to match. Greater matching is achieved with high reflecting products with lower visible light transmittance (14% or below). One method to assist in matching is to use igu’s with the reflective coated surface and an opaque ceramic painted frit on surface. Igu’s create the perception of depth similar to that of the vision panel; reduce condensation and longevityquality problems sometimes associated with other methods below. A second method is to directly bond a plastic opacifier film to a single glazed reflective glass panel on surface. This cost effective factory applied film requires adequate ventilation to avoid damage to the film when excessive heat build up occurs. Opacifier should be cut back in structural silicone glazing situations for maximum bond strength between glass and silicone. With contrasting panels, the use of monolithic or single glazed ceramic fritted glass is commonly used. All spandrel glass panels should be heat strengthened because of the high risk of thermal breakage.

...more

Insulated Glass Units

Be first to Rate

Rate ThisOpening Hours