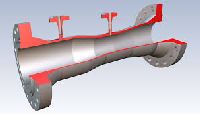

Venturi Tube

15,000 Per Piece

Venturi Tubes

Get Price Quote

We manufacture high quality Venturi Tubes in strict accordance with ASME MFC-3M, BS-1042 and ISO-5167 standards. These tubes give constant accuracy and provide the users with +/- 1.0 % uncertainty of discharge coefficient. These tubes are easy on maintenance and are effectively used in air, water, vapor, steam, gas, chemical substances, sludge and slurry applications. Owing to their excellent construction, these venturi tubes are highly demanded. We manufacture the Venturies in carbon steel, alloy steel like Gr.11, Gr.22 and Gr.91 & stainless steel material. Features : • These can be used for slurries and dirty fluids. • These possess a high pressure recovery. • These have low installation costs and are less prone to erosion. • Very easy to install and can be installed vertically or horizontally. • Being highly durable, they last longer as there are no rotary devices. • We manufacture Venturi Tubes in 2 types :• Machined Type Venturi Tube : 1 inch to 8 inch Size• Fabricated Type Venturi Tube : Above 8 inch size.

Best Deals from Venturi Tubes

Venturi Tubes

Get Price Quote

A fluid passing through smoothly varying constrictions experience changes in velocity and pressure. These changes can be used to measure the flowrate of the fluid. Venturi tubes are available in various sizes from 100 mm to 813 mm with flow coefficient value of 0.984 for all diameter ratios. They are widely used due to low permanent pressure loss. Our manufactured venturis have been in operation in petrochemical, refining, gas pipeline, water, sewage and power plants. We offer Venturi Tubes in SS & CS, DUPLEX & ALUMINIUM. We design it precisely to get accurate flow rate of fluid. Throat is machined for better accuracy in readings. Manufacturing of venturi in strict accordance with ASME MFC-3M, BS-1042 & ISO-5167 standards. Sizes offered vary from 100 mm dia to 1.5 mtr & length upto 6 mtrs. These Venturies are precisely fabricated to get accurate readings.

Venturi Tubes

Get Price Quote

: The venturi can be supplied in any material including plastics. The materials generally used are SA105, SA182F316L, SA182F304L, Inconel, Duplex SS, Monel etc. Venturi upstream pressure tap is located at the mid of inlet cylinder & the downstream pressure tap is located at midpoint of the throat. When averaging is required, the pressure tapping can be taken through piezometric ring or also called as annular ring. This can be manufactured from forging or can even be fabricated from rolling the pipes, as per requirement.

Venturi Tubes

Get Price Quote

1 Piece(s) (MOQ)

the m s group venturi flow element design, developed and perfected by us is a proprietary design offered exclusively by the company for high accuracy and high reliability flow measurement of pressurized line fluids including liquids, gasses, and steam. in its embodiment as the ms group sealed metering system, this revolutionary design accommodates flow measurement of high viscosity line fluids, solids bearing line fluids as well as harsh and/or contaminated line fluids. this design is also available in the rectangular configuration for conduits shaped thusly. this design is available in a variety of configurations, including cast iron pressure vessel, fabricated (welded) metal pressure vessel, plastic insert style, welded insert style, and welded-in pressure vessel style. additionally, the ms group is offered as a cast in place (usually concrete and typically rectangular) configuration. pfs, inc. applications specialists can help you select