Waste Heat Recovery Boilers

Get Price Quote

We provide Waste Heat Recovery Boilers ( WHRB ) / Steam Generators on Natural Gas / Bio Gas /HFO /FO/ HSD based Engines/Turbines and Waste heat coming from different processes like GLASS Furnace exhaust, Melting Furnaces Exhaust, Cement Kiln Waste Gases. The Huge Power Cost Hike and increase of power demand in Industry segment we all has to take each and every chance to trap the waste heat and generate steam possibly for Combined Power Plant or for process steam/Hot water application. The waste heat recovery project is viable only depending on the investment recovery period. We THERMIN ENERGY SYSTEM are very well know this fact and are designing/manufacturing/supplying the systems which gets maximum possible monitory outputs and in minimum time frame. THERMIN ENERGY SYSTEM offers Smoke Tube and Water tube Boilers for such applications. The Systems offering are totally customized turnkey solutions.

Waste Heat Recovery Boilers

Get Price Quote

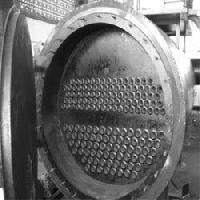

Manufactured in both Smoke Tube and Water Tube Type Construction. Natural or Forced Circulation Type Configuration is possible. WHRU system is designed based on the Waste Gases Type and other Basic Design Parameters, Hence Reliable Operation. Smoke chambers are lined with castable refractory material to protect the inside surfaces. Simple arrangement of smoke chamber door fixing, facilitate easy periodical tube cleaning. Finned Tube Construction is available in water tube forced circulation Waste Heat Recovery arrangement, makes the WHRU compact. Steam Heat Recovery Boilers ar available in both Bi-Drum and Single Drum type arrangements. Due to proper shell or steam drum diameters, steam volume is more & hence better steam quality. Steam Quality is better as Properly Designed Drum Internals are Provided. Provided with accessories like Super Heater, Economiser, Deaerator Tank etc. as per requirement for better performance of the Waste Heat Boiler. Capacity and Working Pressure of the Waste Heat Recovery is considered as per Customers requirement. Heat Exchangers and Waste Heat Recovery Boilers are especially made as per codes like IBR 1950 with its Latest Amendments/TEMA etc.

Best Deals from Waste Heat Recovery Boilers

Waste Heat Recovery Boilers WHRU

Get Price Quote

Waste Heat Recovery Boilers WHRU, turnkey project services

Waste Heat Recovery Boiler

Get Price Quote

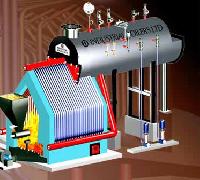

Waste Heat Recovery Boiler is a definite solution to provide energy by utilizing waste heat procured from various processes and applications for the improvement of overall energy balance in numerous industries. We offer a variety of customized as well as turnkey solutions for generating heat, steam and power. Waste Heat Recovery Boiler is also termed as Waste heat recovery unit (WHRU), heat recovery boilers or heat recovery steam generators (HRSGS). The prime objective of Waste Heat Recovery Boiler is to recover maximum energy. Our Waste Heat Recovery Boiler can be available in shell type, construction type and water tube construction. It can be designed under IBR 1950, ASME & TEAM. Waste Heat Recovery Boiler can work on natural circulation as well as forced circulation. Accessories of Waste Heat Recovery Boiler include water pre-heater, economizer and air heater. Waste Heat Recovery Boiler is mainly used in refineries power plants, chemical plants, Petrochemical plants, turbine exhaust, process system and D.G. sets. Highlights : Sturdy construction Longer service life Highly efficient Easy-to-maintain

Waste Heat Recovery Boilers

Get Price Quote

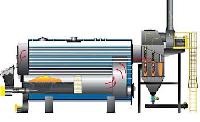

Forbes Marshall Exhaust Gas Waste Heat Recovery Boilers (WHRB) are fully packaged smoke tube industrial boilers equipped with advanced instrumentation to deliver maximum possible heat recovery. These boilers are ideal to recover heat from gen sets, incinerators, blast furnace exhausts etc. They enhance the system efficiency and help save fuel and money.

Waste Heat Recovery Boilers

Get Price Quote

We Design and Supply of Steam Generators on Natural Gas / Bio Gas / HFO / FO / HSD based Engines/Turbines and Waste heat coming from different processes like GLASS Furnace exhaust, Melting Furnaces Exhaust, Cement Waste Gases and Steel Furnaces. The huge power cost hike and increase of power demand in industry segment we all has to take each and every chance to trap the waste heat and generate steam possibly for Combined Power Plant or for process steam application. The waste heat recovery project is viable only depending on the investment recovery period. We "THERMIN" are very well known this fact and are designing/manufacturing/supplying the systems which gets maximum possible monetory outputs and in minimum time frame.

Waste Heat Recovery Boiler

Get Price Quote

Thermax manufactures hot water boilers in the range of 50,000 to 90,00,000 kcal per hour. The hot water boilers are designed to operate on various types of fuels such as heavy oil, light oil, gas, duel fuel, coal, husk and other agro waste fuels. The three types of hot water boilers, manufactured at our unit, are Aquamatic, Aquatherm and Thermocontainers.