Sewage Wastewater Treatment Plant

Get Price Quote

1 Piece (MOQ)

water treatment plant equipment

50,000 Per Piece

1 Piece (MOQ)

Best Deals from Wastewater Treatment Plant

Sequential Batch Reactor

Get Price Quote

1 Piece (MOQ)

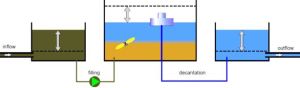

SBR type STP works on the principle of batch treatment of the sewage. Sewage is collected & fed to the reactor in 4 or 5 batches. Air is supplied & the completed aerobic process takes 2 hrs per batch. Once aeration is finished, the sewage comes to a stand-still position so that all suspended solids settle at the bottom thus clarifying the water. Clarified water is then decanted out to be collected In the clarified water tank. This water is further disim fected, filtered & stored or drained. SBR has following features : » Automatic operation of the reactor controlled by a PLC. » Single Tank Operation. » No media addition / replacement. » Intermittent operation so less maintenance. » Low sludge yield, typically once in 10-12 days. » Possible In open, underground & basements. » Water can be reused for gardening & flushing

Ultra Filtration Water Treatment Plant

300,000 - 800,000 Per Set

1 Set (MOQ)

Effluent Treatment Plant

Get Price Quote

1 Piece (MOQ)

Wastewater Treatment Plant

100,050 Per Unit

1 Unit (MOQ)

Effluent Treatment Plant

Get Price Quote

1 piece (MOQ)

we are offering effluent treatment plant.industrial waste water treatement.

Wastewater Treatment Plant

100,000 - 1,000,000 Per Piece

1 Piece(s) (MOQ)

Due to our superior transit system and vast distribution network, buyers can be rest assured for timely delivery. One of the major concerns of the organization is to make available only quality approved products to the buyers and thus we check the entire range at all stages.

Wastewater Treatment Equipment

Get Price Quote

We manufacture & supply all categories of DM plant, Ozonation, filter press, Centrifugal decanter, sludge dewatering systems available. As per requirement we also supply tailor-made solutions to our clients.

Effluent Treatment Plant

200,000 - 5,000,000 Per

The treatment to remove organic and inorganic impurities, suspended and dissolved particles and contaminants from industrial effluent wastewater with the help of different technologies for keeping industrial environment clean and green.

Wastewater Treatment Plant

550,000 - 4,500,000 Per plant

We abide by the strict delivery policies and thus, we ensure that the products are sternly packed and delivered on time. We have tied-up with the leading names offering qualitative raw material. Also, we check on several parameters prior to procurement for ensuring high quality standards. Features Advanced mechanism Purity guaranteed High productivity

PLC Wastewater Treatment Plant

250,000 Per Set

All types of water treatment system, with flow control and reporting system for easy of access of plant.

Effluent Treatment Plant

Get Price Quote

The Effluent Treatment Plant, provided by us, is known for its quality. To make sure that we offer only defect-free range of products, our quality experts cross check every product at diverse stages. Using premium packaging materials, we secure our products properly for transportation and label it properly to provide information such as address of manufacturer/distributors, MRP, quantity, etc.

Water Treatment Equipment

Get Price Quote

Scaling: Scaling occurs when a mineral film coats the entire heat transfer surface of Heat exchanger OR Condenser. These mineral deposits such as Calcium, lime, Mud and rust rob heat transfer efficiency. This increases energy cost by over 30 %. Heat Exchangers, Condensers and even Cooling Towers therefore require DESCALING maintenance to improve their efficiency. Evaporative Condenser: When water scale is deposited on the heat transfer surface of an evaporative Condenser, the cooling water from the spray head can not efficiently condense the refrigerant gas in the coils. As a result inadequate cooling , over worked machinery and expensive operation is incurred. Shell & Tube Condensers: Water scale deposits in the condenser coils cause the compressor to kick out on high head pressure and lowers the cooling capacity of the unit. Cooling Towers: Basic principle of Cooling Tower is to cool the water that has picked up heat generated by equipment within facility. Cooling tower design enhances evaporation & allows further cooling of tower water. This water is then pumped into the facility continuing to cool the equipment Scaling within cooling tower can restrict the water distribution of spray nozzles, reduce the water flow thru the openings of a hot deck and restrict the air flow within the tower. All these conditions result in diminished cooling capacity & inefficient operation of the associated equipment in the cooling tower system. Absorption Units: Water scale accumulating on the water side of Absorbers & Condensers materially affects the operation and efficiency of any absorber type Air-conditioning unit. The harder the water, the faster the deposit accumulates. Scaling of Plastic Molding Machines : Cooling is an important process in the production of injection mold To molders, scale, caused by calcium in hard water, is a devil that forms as Water flows through pipes, contaminating and clogging lines throughout a plant. When scale builds up in the pipes and heat exchangers on a molding machine’s hydraulic system, it causes poor heat transfer, which prevents molders from running their machines at full capacity. Similarly, when scale clogs mold cooling water passages , it creates a thermal barrier that hinders the cooling and heating of the mold. All of this adds up to wasted machine time and money. Injection molding machines are typically run at about 65 to 75 percent of their fastest cycle times because of poor heat transfer. It takes just a 1/16-inch-thick build up of scale to cause a 15 percent slowdown in a machine’s cycle because it takes longer to extract the heat. A uniform cooling process is desired to avoid defects in manufactured parts. How to Get Rid of Scaling : Scale can not be removed by hydro blasting or typical scrubbing. The only reliable way to remove these scales is by Descaling Agent . A Descaling agent or chemical descaler is a chemical substance used to remove limescale from metal surfaces in contact with hot water, such as in boilers, water heaters, and kettles. Descaling agents are typically acidic compounds such as hydrochloric acid that react with the alkaline carbonate compounds present in the scale, producing carbon dioxide gas and a soluble salt. Notable Descaling agents include acetic acid, citric acid, glycolic acid, formic acid, phosphoric acid, sulfamic acid and hydrochloric acid. Descaling process needs to be done frequently Chemicals are used. So additional expenditure. Plant shut down is required resulting in loss of production. Softening plant is required. Costly man power required. All this can be eliminated by using SCALE-AQUA , a unique online non chemical No power Descaling equipment. Advantages of Scale Aqua Installation : SCALE-AQUA, prevents deposition of hard scale in the heat transfer area. SCALE-AQUA, is fitted in existing pipeline with absolutely no changes in the pipeline. SCALE-AQUA is tested at water hardness of 5,000 PPM & TDS of 20,000 PPM SCALE-AQUA, gives excellent water saving. SCALE-AQUA is an online equipment which is fitted just before evaporative condensers, Heat Exchanger (PHE) , and Boiler, coil, Compressors, Chilling plants.

Packaged Wastewater Treatment Plant

Get Price Quote

Water Treatment Equipment

Get Price Quote

We are care chem enterprises dealing in lab- materials,api's chemicals,reagents, solvents, indicators, glass wares, plastic wares porcelain wares and laboratory scientific equipment and setup of all laboratories with good quality materials at minimum possible price. we also deal with operation theater setup, aseptic room make up and maintenance and clean room with cabinet (air blower) aseptic garment racks. we believe in good quality product supply with minimum lower possible cost. it will be our pleasure. If we could help you to provide maximum product service with best quality at minimum cost we will fill proud if you order us for better surveillance of your best institute industry. assuring you of our continued commitment to provide quality products and services and our desire to contribute significantly towards success of your plans and activities, we remain.

Industrial Reverse Osmosis Plant

Get Price Quote

Our online validation transactions are supported for Electronic Funds Transfer ensuring complete security of the payments. We also undertake offline payment methods such as bank account transfer, cash payment, etc. Assistance from the smart packaging system has enabled us to meet bulk and customized packaging requirements of the clients. In addition, our experts ensure safe packaging of the products.

Industrial Reverse Osmosis Plant

Get Price Quote

Effluent Treatment Plant

Get Price Quote

We Design, Manufacture, Supply, Erect and Commission Effluent Treatment Plant (ETP) on Turnkey basis for various types and natures of wastewaters, effluents which combines advanced physico-chemical treatment processes with tertiary polishing system for the removal of organic, inorganic, oil and grease, heavy metals & suspended solids. These Effluent Treatment Plants are manufactured in confirmation to the set industrial standards. Our Methodology We analyze the effluent samples for different effluent parameters as per nature and compositions, carry out the treatability studies by using different methods checking techno-commercial Feasibility and then designed treatment schemes, processes accordingly to suit the purpose and need. Our ETP systems are very compact, tailor made designs, portable required very less foot-print to accommodate, energy efficient. The up-gradation, modification in the existing ETP system is possible to achieve desired limiting standard laid down by the Pollution Control Board (PCB).  Our Strength Our Strength lies in having our own Water and Waste Water (Effluent) Testing Laboratory, facility to a test water and effluent parameters, finding of the problematic areas, carrying out the treatability in different ways to conclude the treatment methodology in laboratory before starting the actual treatment plant work at Clients site. More than 13 years of experience to handle different grades of effluents and more than 400 no. of Installations across India and abroad.We are also introducing the latest technology like Ozonisation, UF, RO and Multiple effect evaporation system to achieve the zero discharge norms.This highest quality treated water which can be suitably recycle back to process or used for the Process (recycle), Gardening, Toilet Flushing and Floor washing purposes. The Principle The principle of operation of ETP is Physico-Chemical treatment followed by Polishing Treatments like �Sand Filtration, Activated Charcoal treatment (Adsorption), Ozonisation (Chemical Oxidation), Ultra Filtration (UF), Reverse Osmosis (RO) and evaporation (If required). Salient Features Very cost effective : Less initial Investment. Types : Batch and Continuous. Atomization : Manual, Semi-automatic and Fully-automatic.Compact and proven design : Required very Low foot print.Quality Components and Mounting items : Special sludge pump and total corrosion free UPVC piping & FRP/Epoxy Lined MS tanks.Water Recycle : Recycling of treated is possible with advanced treatment methodology like UF and RO.Operation and maintenance : Very silent in operation and any unskilled person can operate it, after proper training.Flexible design : Starting from 0.5 m3/day to 500 m3/day capacities.Recurring Expenses : Economical plant operating cost, required regular treatment chemicals available in the market Applications AutomobileIndustryChemicalIndustryMetalPretreatmentElectroplatingPharmaceuticalTextilePaper MillsDairiesSugar MillsLeather IndustriesPetrochemical

Effluent Treatment Plant

Get Price Quote

Effluent Treatment Plant, which we offer, is widely used in the treatment of generated waste in an economic manner, as per pollution board norms. The offered Effluent Treatment Plant is very helpful in reduction of operating costs, and thus increasing profits. Effluent Treatment Plant helps in achieving more effective conformity with legislation. Also, the Effluent Treatment Plant improves company's public image. Features Optimum performanceReliableDurable finishQuality tested Minimum Order Quantity : 10 units