1000 LPH Ghee Clarifier

Get Price Quote

1 Piece (MOQ)

ANDEROL FGCS 2 GREASE

Domestic Ro Water Purifiers

3,300 Per RS

05 Pair (MOQ)

Best Deals from Water Treatment Plant

Industrial Demineralization Plants / Systems

Get Price Quote

We are Manufacturer, Supplier, Exporter of Industrial Demineralization Plants / Systems (DM Water Treatment Plants) and our setup is situated in Pune, Maharashtra, India. We are also Services Provider of above products in Mumbai, Nashik, Aurangabad, Kolhapur, Sangli, Satara, Raigad, Maharashtra, Gujrat and Karanataka, India About Demineralization System Demineralization, also referred to as deionization (DI), stands as a vital water treatment method designed to eliminate dissolved minerals, ions, and salts from water. Using ion exchange resins, this process swaps positively and negatively charged ions in water with hydrogen and hydroxyl ions, resulting in exceptionally purified water. In demineralization, three main types of media are utilized: Cation Exchange Resin, targeting positively charged ions; Anion Exchange Resin, removing negatively charged ions; and Mixed-Bed Resin, a combination of cation and anion resins for comprehensive demineralization. Regeneration is a crucial step in demineralization, aiming to restore resin capacity. Specific chemicals like hydrochloric acid for cation exchange resins and sodium hydroxide for anion exchange resins are passed through the resin during this process. Commonly used chemicals for resin regeneration include hydrochloric acid, sulfuric acid, sodium hydroxide, or potassium hydroxide. OBR, which measures the resin's capacity before regeneration, plays a key role in determining system efficiency. It's calculated based on resin volume and the concentration of removed ions. Demineralization systems serve as integral components in various industries, ensuring water purity and meeting stringent quality standards. This overview provides a comprehensive understanding of demineralization systems, covering their processes, chemicals involved, and the significance of OBR, catering to those seeking detailed insights into water treatment technologies.

Reverse Osmosis Plants

Get Price Quote

Industrial Ro Plant

800,000 - 850,000 Per Piece

1 Piece (MOQ)

RO Drinking Water Plant

175,000 - 450,000 Per Piece

1 Piece (MOQ)

Our firm is one of the well-known names in the industry for the Manufacturing of a large array of Reverse Osmosis System, Water Softener, Water Treatment Plant And System, DM Plant, Pouch Packing Machine, Shrink Wrapping Machine.

Water Demineralization Plant

55,000 - 1,200,000 Per Set

1 Set (MOQ)

50 LPH Domestic RO Water Purifier

4,999 Per Piece

1 Piece (MOQ)

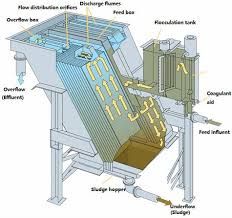

sludge contact clarifiers

Get Price Quote

We design, manufacture and supply wide range of clarifiers, tube settlers & Clariflocculators. These systems are widely used for River Water, sewage water, effluent and waste water treatment system for removal or settling of suspended particles. The entire assortment is designed to meet client�s requirement and is available in different Specifications. These systems are available with Dosing system, Flash Mixer followed by clarifier system such as tube Settler or convectional clarifier. Clarifiers settle suspended as well as colloidal particles under gravity and have the potential to provide large projected surface area.

Sewage Treatment Plant

250,000 - 1,500,000 Per Nos

01 Set (MOQ)

Reverse Osmosis Plant

145,000 Per Piece

Open RO

Get Price Quote

15 LPH Purification capacity : 15 Ltr Hour Duty cycle: 75 Ltr Day(Max) Booster pump : 100 GPD RO Membrane : 80 GPD, Consealed Type Installation : Wall mounted Power Supply : Input - 110V to 330V Ac, Output - 24V DC = 2.5 Amp

Ghee Clarifier

Get Price Quote

We use superior-grade packaging as barrier protection for our products against dust, moisture, mechanical damages and logistical jostling. Our products packaging is premium. Our payment procedures are well documented, legal, and safe. We provide our clients with numerous online and offline options for making purchases and make sure they are protected.

Vertical Lamella Clarifier

550,000 - 800,000 Per Piece

1 Piece(s) (MOQ)

Functioning smoothly from Pune(India); we are capable enough of serving the clients in a shortest time possible. We facilitate trade by providing you varied payment options like payment through online as well as offline modes.

High Vacuum Transformer Oil Filtration Plant

Get Price Quote

Electric transformers perform best when the insulating oil is devoid of moisture, dissolved gases and unwanted particles. Even new oils require some treatment to limit these contents to suitable levels. Contaminated oil loses its characteristics of dielectric strengths, resistivity and loss factor. Excessive moisture leads to acid and sludge formation. CEE DEE VACUUM EQUIPMENT PVT LTD designs transformer oil filtration and purification plants that are utilised for dehydration, filtration and degassing of insulating oil. This easy-to-operate and compact equipment has a degassing column with single, two or three stage versions. Known for its precise engineering, these plants are manufactured in different specifications to suit the needs of diverse applications.

ss ro plant

450,000 - 700,000 Per Piece

1 Piece (MOQ)

Fully automatic ss Ro plant 500-5000LPH .best price for more information and price details cal 8793806340

Wastewater Treatment Plant

550,000 - 4,500,000 Per plant

We abide by the strict delivery policies and thus, we ensure that the products are sternly packed and delivered on time. We have tied-up with the leading names offering qualitative raw material. Also, we check on several parameters prior to procurement for ensuring high quality standards. Features Advanced mechanism Purity guaranteed High productivity

Cabinet Type Reverse Osmosis System

Get Price Quote

Model Name/Number BMEPL Brand BMEPL RO Capacity 1000(Liter/hour) RO Membrane Type Cabinet RO Plant

Ash Slurry Disposal System

Get Price Quote

Flow quantity of Slurry and pressure required are the basic parameters required for designing the system. However, these two parameters in turn depend on many other conditions like rate of ash to be disposed, pipeline distance, pipeline profile, density of slurry, viscosity of slurry etc. Moreover ash is highly abrasive and pipeline wear also needs to be considered. A critical aspect of system is selection of slurry velocity in the pipeline which should be low to minimize abrasion but high enough to avoid settling of Ash in the pipeline.Slurry with low or medium concentration (usually 45% to 50% by weight) can be pumped using centrifugal slurry pumps. The viscosity of slurry does not have much effect for such conditions while calculating pressure requirement, but as the slurry concentration increases the viscosity effect has a dominant effect for calculating pressure requirement. Generally ash slurry pumping beyond 65% in not feasible, as high concentration slurry requires extremely high pressure which increases exponentially as per the concentration. Such high pressures can be developed using piston diaphragm pumps. These pumps can develop very high pressures but are very costly and have a very high maintenance cost. The high pressures result in higher power consumption though the water requirement is lower in this system.

J1 REPPO 7 Alkaline Water Ionizer

185,000 Per Unit

5 Piece (MOQ)

A device which aims to increase the quality and health benefits associated with drinking water. J1 Ionized water is natural water that has been run through an ionizer machine's platinum and titanium plates to exchange some of the titanium and platinum ions with the water, thereby increasing its alkaline nature and the pH level of natural water.

Water Treatment System

Get Price Quote

aqua grand plus ro water purifier

Get Price Quote

Aqua Clear Solution, entered in the Household water purifier business in August 2015, has announced the expansion of its range of stylish and differentiated products. New Aqua Grand(Smart) Plus is the initiative for the Company's future growth plans to expand its presence in related new product categories. Aqua Clear Solution has launched a range of models, these are variants in the electric devices category namely RO, UV, TDS and Minerals. We are offering Aqua Grand in different ways as New Aqua Grand(Smart) Plus (Ro + Uv + Tds + Minerals). New Aqua Grand (Smart) Plus (Ro + Uv + Uf + Tds + Minerals) and Copper Ro with Active Copper Elements with prices varying from 5,499 to 12,499.

DM Plant

Get Price Quote

A Typical two-bed DM Plant consists of two MS Rubber lined Pressure vessels connected in series along with its internal fittings. The first unit consists of high capacity strongly acidic cation exchange resin, which converts positive ions of salt and replaces them with hydrogen ions to form respective acids, which are absorbed in next vessel by strongly basic anion exchange resin. The water obtained by this process shows conductivity less than 20 µ S cm at 25 Deg C and total dissolved solids less than 10 ppm.Further high purity water can be achieved by Mixed Bed Deionisers, which are designed to produce high purity treated water. They can be used as polishing units after two bed DM Plant to obtain high purity water. Mixed Bed Deionisers are single column units, filled with strongly acidic cation and strongly basic anion exchange resins mixed together.

RO Water Purifier

6,500 Per Piece

We are the main supplier of this product.

PLC Wastewater Treatment Plant

250,000 Per Set

All types of water treatment system, with flow control and reporting system for easy of access of plant.

BactaServe Bio Culture- Eflluent Treatment Plant

1,900 Per Kilogram

10 Kilogram (MOQ)

Product Details: Anaerobic Bioculture for Dairy, Pharma, Chemical Industry ETP Wastewater Treatment Product Name: Anaerobic Bioculture for Dairy, Pharma, Chemical Industry ETP Wastewater Treatment Product Type: Anaerobic Bioculture Description: The Anaerobic Bioculture is a specialized microbial solution designed for the effective treatment of effluent wastewater in the dairy, pharmaceutical, and chemical industries. This bioculture enhances the anaerobic digestion process, leading to efficient degradation of organic pollutants and improved wastewater treatment outcomes. Key Features: High Efficiency: Optimized for rapid degradation of complex organic compounds. Industry-Specific: Tailored for dairy, pharmaceutical, and chemical industry effluent treatment plants (ETPs). Eco-Friendly: Promotes natural anaerobic digestion, reducing environmental impact. Enhanced Biodegradation: Facilitates the breakdown of difficult-to-treat substances. Cost-Effective: Reduces the need for additional chemical treatments and lowers operational costs. Applications: Dairy industry effluent treatment plants (ETPs) Pharmaceutical industry wastewater management Chemical industry effluent treatment Industrial wastewater treatment facilities Benefits: Improves the efficiency of anaerobic digestion processes Reduces sludge volume and handling costs Minimizes unpleasant odors associated with wastewater treatment Lowers energy consumption in wastewater treatment plants Ensures compliance with environmental regulations and discharge standards Enhances the quality of treated effluent, making it safer for discharge or reuse Usage Instructions: Introduce the Anaerobic Bioculture directly into the effluent treatment plant as per the recommended dosage. Regular monitoring and maintenance are essential to achieve optimal results. Packaging: Available in various sizes to suit different treatment plant capacities and needs. Safety and Storage: Store in a cool, dry place away from direct sunlight. Keep out of reach of children. Follow the safety guidelines provided on the packaging. Manufacturer:Amalgam BiotechA Division of AMalgam EngineeringBaner, Pune 411045Contact Information: Given aboveNote: For specific dosage recommendations and technical support, please refer to the product manual or contact our technical team.

Hot Water Generators

Get Price Quote

We Manufacturing High Quality Hot Water Gnerators, Our Hot Water Generator Come With Robust Construction And Easy Operation For Direct & Indiredct Firing.Wide Range: 30,000 Kcal/Hr to 30,00,000 Kcal/Hr.Heat Output: UP to 120 Deg.CFuel:- Solid fuel, LDO, FO, LSHS, Electrical & Etc. Description The hot Water generators are offered in vertical or horizontal designs, either as standard models or tailor-made models to match customer's specifications and applications. Designed in DIRECT and INDIRECT heating types, these systems are practically free from any maintenance and are highly efficient. Salient Features of the Hot Water Generators are Durable construction Easy operation and minimal maintenance High level of safety in operation, thus greater reliability Optional recirculation system to improve overall thermal efficiency Fully automatic burner control and temperature control Units are available from capacities of 30,000 Kcal/hr to 30,00,000 Kcals/hr. Imported & indigenous burners can be supplied with various firing options like light oil, heavy oil & gas. Units can be manufactured in various materials of construction like SS. Units can be supplied with optional imported burners.

Lamella Clarifier

Get Price Quote

Lamella plate clarifier configuration ensures laminar flow conditions, which results in hydraulic uniformity and high effluent quality. It permits great reduction in the space needed for clarification equipment and allows the compact equipment to be located indoors if desired, or to be easily relocated at a later date. It also makes point-source treatment not only feasible, but logical for many applications. The Lamella Clarifier system consists of a series of inclined overlapping plates, which are arranged to form separate sedimentation chambers or cells between each pair of adjacent plates. The overlapping additive projected area of the plates is a factor of increased surface settling which is proportional to the number of plates used. lamella clarifier system Features and Options: Standard Features: ���» Structural steel support legs ���» 1/4" minimum tank wall thickness ���» Epoxy painted carbon steel tank ���» Individually removable FRP plates ���» Adjustable effluent weir plates ���» Standard units can be manufactured for flows from 2 to 75 m3/hr and above, in a single above grade tank ���» One-piece prefabricated units are available with up to 1000 square ft. of effective settling area. ���» One-piece construction with integral flash mix/floc compartments for smaller units

Sewage Treatment Plant

Get Price Quote

Using Our Cutting Edge Technology, We are Able to Provide Brilliant Quality Sewage Water Treatment Plant. Our Industrial ,Sewage Treatment Plant is Precisely Designed to Eradicate Sewage Problems such as Contamination of Water, Choked Water Etc. We are Counted among the Supreme Sewage Treatment Plant Manufacturers, Based in India.

Water Purifier

Get Price Quote

We are main supplier of this product.