Water Treatment Equipment

Get Price Quote

Scaling: Scaling occurs when a mineral film coats the entire heat transfer surface of Heat exchanger OR Condenser. These mineral deposits such as Calcium, lime, Mud and rust rob heat transfer efficiency. This increases energy cost by over 30 %. Heat Exchangers, Condensers and even Cooling Towers therefore require DESCALING maintenance to improve their efficiency. Evaporative Condenser: When water scale is deposited on the heat transfer surface of an evaporative Condenser, the cooling water from the spray head can not efficiently condense the refrigerant gas in the coils. As a result inadequate cooling , over worked machinery and expensive operation is incurred. Shell & Tube Condensers: Water scale deposits in the condenser coils cause the compressor to kick out on high head pressure and lowers the cooling capacity of the unit. Cooling Towers: Basic principle of Cooling Tower is to cool the water that has picked up heat generated by equipment within facility. Cooling tower design enhances evaporation & allows further cooling of tower water. This water is then pumped into the facility continuing to cool the equipment Scaling within cooling tower can restrict the water distribution of spray nozzles, reduce the water flow thru the openings of a hot deck and restrict the air flow within the tower. All these conditions result in diminished cooling capacity & inefficient operation of the associated equipment in the cooling tower system. Absorption Units: Water scale accumulating on the water side of Absorbers & Condensers materially affects the operation and efficiency of any absorber type Air-conditioning unit. The harder the water, the faster the deposit accumulates. Scaling of Plastic Molding Machines : Cooling is an important process in the production of injection mold To molders, scale, caused by calcium in hard water, is a devil that forms as Water flows through pipes, contaminating and clogging lines throughout a plant. When scale builds up in the pipes and heat exchangers on a molding machine’s hydraulic system, it causes poor heat transfer, which prevents molders from running their machines at full capacity. Similarly, when scale clogs mold cooling water passages , it creates a thermal barrier that hinders the cooling and heating of the mold. All of this adds up to wasted machine time and money. Injection molding machines are typically run at about 65 to 75 percent of their fastest cycle times because of poor heat transfer. It takes just a 1/16-inch-thick build up of scale to cause a 15 percent slowdown in a machine’s cycle because it takes longer to extract the heat. A uniform cooling process is desired to avoid defects in manufactured parts. How to Get Rid of Scaling : Scale can not be removed by hydro blasting or typical scrubbing. The only reliable way to remove these scales is by Descaling Agent . A Descaling agent or chemical descaler is a chemical substance used to remove limescale from metal surfaces in contact with hot water, such as in boilers, water heaters, and kettles. Descaling agents are typically acidic compounds such as hydrochloric acid that react with the alkaline carbonate compounds present in the scale, producing carbon dioxide gas and a soluble salt. Notable Descaling agents include acetic acid, citric acid, glycolic acid, formic acid, phosphoric acid, sulfamic acid and hydrochloric acid. Descaling process needs to be done frequently Chemicals are used. So additional expenditure. Plant shut down is required resulting in loss of production. Softening plant is required. Costly man power required. All this can be eliminated by using SCALE-AQUA , a unique online non chemical No power Descaling equipment. Advantages of Scale Aqua Installation : SCALE-AQUA, prevents deposition of hard scale in the heat transfer area. SCALE-AQUA, is fitted in existing pipeline with absolutely no changes in the pipeline. SCALE-AQUA is tested at water hardness of 5,000 PPM & TDS of 20,000 PPM SCALE-AQUA, gives excellent water saving. SCALE-AQUA is an online equipment which is fitted just before evaporative condensers, Heat Exchanger (PHE) , and Boiler, coil, Compressors, Chilling plants.

Well Point Dewatering

Get Price Quote

Well points are smaller diameter tubes with slot near the bottom that are inserted into the ground from which water is drawn by a vacumm generated by a dewatering pump.System consist of number of well points spaced along a trench,all connected to common header, which is attached to one or better points pump.

Best Deals from Water Treatment Plant

PLC Wastewater Treatment Plant

Get Price Quote

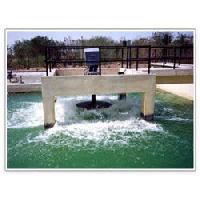

Submersible Jet Aerator

24,000 - 25,000 Per Piece

Sewage Treatment Plant

Get Price Quote

We are involved in superior quality Sewage Treatment Plant to the valued clients. The internal controls of the Sewage Treatment Plants are adjusted during factory testing and do not require subsequent re-adjustments. We offer the Sewage Treatment Plant at competitive prices to clients.

Industrial Water Pump

Get Price Quote

The cooling system of the engine (V92S2 & V46) is of a closed, high temperature type, with forced circulation and ejection cooling radiators. The system provides for dissipation of heat from the engine parts containing hot gases and maintains their temperature within permissible limits. The coolant used is water.Used on : T90, T72 tanks.

Hot Water Generators

Get Price Quote

Hot Water Generator

Get Price Quote

We design and manufacture waste heat recovery unit to capture available waste heat for water heating.This hot water can be used for various purposes like-Boiler feed water, process water, to run absorption chillers etc .

Water Cooled Generator

Get Price Quote

Fuel Type: Diesel kW: 6.1 Shaft: Horizontal Cylinders: Single Cooling: Air Emission Compliance: CPCB II, BHARAT (TREM) STAGE III A Engine Type: Commercial

chilled water plants

Get Price Quote

Features :• Capacities from 5 TR to 300 TR• Available with Cupro Nickel 70: 30 & 90: 10 condensers• Evaporators- Brazed plate heat exchangers & shell & tube type• Mobile chilled water plants• Mobile chilled air plants• Compact & sturdy design• In-house testing facility• Factory acceptance trials

Nano Filtration Plant

100,000 Per Units

Flash Mixer

90,000 Per Piece

Oil Filtration Plant

Get Price Quote

zero liquid discharge system

1,500,000 Per Piece

Wastewater Treatment Equipment

675,000 Per Unit

1 Unit (MOQ)

mobile transformer oil filtration plant

Get Price Quote

During its operation of generating, transmitting and distributing power transformers give out heat which is absorbed by insulating oils. This oil has a tendency to absorb moisture from windings which leads to gradual deterioration of dielectric strength. Our filtration systems provide economical and efficient methods of purifying this lubricant. The unit consists of:Filter Unit, Indirect system of Oil Heating, Vacuum Dehydration / degasification Unit Condenser and condensate receiver Feed and delivery pump Piping & Valves Control Panel Components of Plant:The filter unit is a coarse strainer with a wire mesh filter element for retaining solid particles and a powerful magnet for retaining magnetic particles. It has round filter paper discs held under spring compression. Specially designed heaters with low watt density heat the auxiliary heating oil, which in turn heats the transformer oil maintaining a temperature of 70-80 C. The cylindrical external pressure vessel is fitted with various shallow drip trays and a specially designed spray pipe to increase surface area. The vapor from dehydration chamber is condensed in a condensate receiver of welded M. S. construction. There are feed and delivery pump of rotary gear type coupled directly with motors. Water Separator Collect the water produced. A centralized control panel has indicators for all electrical devices. Imported thermostat Thermometer for measuring temperature Pressure & Vacuum gauges Flow control indicator lectronic Float Control Electrical instruments, voltometers and ammeters Electrical overloads and overload releases for safety of motors.

Ultra Filtration Plants

Get Price Quote

Ultra Filteration (UF) – Membrane Technology We make the Ultrafiltration Units of sizes and capacities from 500 LPH- 30,000 LPH as a modules.It is known fact about the Ultrafilteration that the porocity of 1.2mm-1.3mm dia Hollow fibers ( PES, PVDF ect.) is about 0.1 to 0.01 micron though there are membranes which ranges even lower than 0.01 microns. The uses of UF is mainly a part of Pre treatment for the Down stream units of RO systems.The UF works on either Dead End or Cross flow type configuration and also as Out to In or In to Out type configuration.Probable application area in the water Purification is for removal of Bacteria/virus micro organisms, as well as the fine suspended particles such as color/dyes ect.Also the removal of Colloidal particles such as Colloidal Silica in the boiler feed water, The dairy industry uses UF technic for Whey Proteins separation.Molecular weight cut off is the criteria for the selection of type of membranes.Along with the hollow fine fiber type membranes , the Spiral wound ( similar to Reverse Osmosis) membranes are also actively used in the UF plants.The UF needs periodic (every 40-50 minutes depending on the feed water conditions ) Backwashing of 30-50 seconds. Which is of course done automatically. The in side to Out configuration mostly needs The periodic Chemical Enhanced Backwashing or CEB, with High pH (10-11) Sodium Hydroxide plus Hypo Chlorite, followed by Low pH of ( 3-4) with help Citric acid or Dilute HCl. It is observed as per the design guidelines that The Out to In Configuration calls for Air Scouring and Hypo Backwashing instead of CEB. The CIP ( Cleaning in Place) is done generally for both, IN-OUT or OUT-IN configurations. Very similar to that of RO CIP cleaning procedure to Regain Flux.

Waste Water Treatment Plant

Get Price Quote

There are many reasons why we must move forward with the wastewater project for the core area, not only to meet the federal regulations and provincial requirements. Managing wastewater is more than just selecting the technology; it also involves testing and knowing what is in the wastewater. Treatment is part of the solution to manage impacts from the waste we produce, but we can also help by being more diligent in the personal-care and products we use. Wastewater treatment is a continuum and it must be built to provide flexibility for the future as regulations or needs change. We at COEP understand this need of waste water treatment in Industry today and offer a wide range of steel tanks for storage of high volumes of waste and treated water. Our water tanks ranges from 10,000 litres up to 20 lakh litres and can be used to store waste water, intermediate water and treated water. Used by the food, pharma, textile,engineering,mining and processing industries COEP Tanks are designed to suit project requirements and a highly cost effective solutions can be found. COEP Prefab tanks have wide range and are suited to the requirement without compromising on quality, longevity or safety.

Industrial Ro Plant

Get Price Quote

industrial ro plant manufacturer for capecity starts from 100 liter per hour to 5000 ltr per hour .

RO Water Purifier

7,500 - 14,500 Per Rs

1 Piece (MOQ)

Effluent Water Treatment System

Get Price Quote

Effluent Water Treatment System, paper pulp bleach plant

Waste Water Treatment Plant

Get Price Quote

We Offer Waste Water Treatment Plant. Cmplete solution for industrial wastewater treatment plant by providing following technologies 1. Screening 2. Removal of O&G 3. Removal of TSS 4. Physico-chemical treatment processes 5. Advance Ananerobic and Aerobic biological treatment solutions including MBBR, MBR, SBR etc. 6. Zero Liquid Discharge solutions by providing Multi Effect Evaporation System with Crystelizers. 7. Membrane Based solutions like UF, RO, Nano etc.

Fixed Aerator

Get Price Quote

Fixed Aerator, chlorine generators, Ro Plant, Clarifier, clariflocculator

Water and Wastewater Treatment

Get Price Quote

Marketing diagnostics service, Paints and Coatings, Solvents Surfactants

Dewatering System

Get Price Quote

Dewatering System, monobelt filter press, sludge thickeners, Screw Press

Water Treatment Plants

Get Price Quote

Reverse Osmosis Plants, Wastewater Treatment Plants

Waste Water Treatment Equipment

Get Price Quote

Waste Water Treatment Equipment

uv systems

Get Price Quote

uv systems, UV Lamps

Effluent Treatment Plant

Get Price Quote

Cooling Tower, cooling tower fill, Chlorinator, exhauster, Water Chiller

Sewage Treatment Plant

Get Price Quote

Sewage Treatment Plant, Biogas Plant, Fly Ash Disposal System