Hot Plate Welding Machine

Get Price Quote

1 Piece (MOQ)

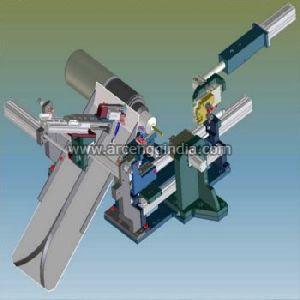

Robotic Welding Fixtures

Get Price Quote

1 Piece (MOQ)

We are Manufacturer, Supplier, Exporter of Welding Fixture Lines, Welding Line Fixtures. Designing as well as in manufacturing of the welding fixtures. . our team is capable to handle all kind of welding fixtures. Started from the weld lines for two wheeler and now we have also stepped into the four wheeler. We are proud to say that we have worked for world wide renowned companies.

Best Deals from Welding Machine Parts

Spot Welding Controllers

Get Price Quote

1 Piece(s) (MOQ)

We are offering spot welding controllers. For the best quality spot welding controllers, “s. S. Controls” is the perfect destination for you. The micro controller based spot welding controllers made accessible by us are find their application in different kinds of welding machines like table mounted microspot welders and manually operated (rocker arm type or similar) spot welding machine. They are known for their low maintenance cost. The precise time and energy control of these controllers ensures consistent weld quality. Besides, we are one of the eminent spot welding machine controller manufacturers in india.

Spot Welding Fixtures

Get Price Quote

Spot Welding Fixtures are offered at cost effective prices to our clients. these fixtures for recognized clients such as Telco, primier auto and many more. Due to our advanced machinery and quality consciousness, Our range of welding fixtures assures high performance and less maintenance.

SFC Robotic Welding Fixture

810,000 - 1,500,000 Per Piece

1 Piece (MOQ)

Cold Wire Feeder

94,000 Per piece

1 piece (MOQ)

Welding Positioner

Get Price Quote

1 Piece (MOQ)

After the goods are sternly examined by the experts, the picking, checking, labeling and packing commences in the substantial warehouse. Sprawling over a large area, we ensure that the goods are packed with utmost proficiency. The assistance of our quality auditors helps us in acquiring quality-approved raw materials from the certified vendors. Thus, we ensure that our products are of unmatched quality. Product Range : 2 ton to 230 ton job handling capability

Hydraulic Operated Quill Feed Unit

Get Price Quote

A Hydraulic operated quill feed unit is not just an automatic drill press but much more than that. It is modular, automated machining which usually has two or more axes of motion. One us the linear feed and the other one is the spindle rotation. This mechanism feed can be hydraulic, mechanical or pneumatic and can extend to the spindle in the quill. The feed unit can do everything starting from basic drilling to tapping and more exotic application such as a combination of reaming and drilling, twisting and even thread rolling. If you are in search of a feed unit get it from us at Paston Machines PVT. Ltd. We are the best Hydraulic Operated Quill Feed Unit Manufacturer. Our products are the best and long-lasting. For any kind of queries and questions related to our products and services, you can ask us directly through the help link or by directly calling us.

Welding Machine

8,000 - 12,000 Per Piece

Metal Building Material

Get Price Quote

200 Meter (MOQ)

Roof sheets, Cladding materials, Metal building materials, Insulated metal Roof and wall sandwich panels, Z & C Purlins, Decking sheets, Corrugated sheets, Box Profile sheets/ Trapezoidal sheets, Wave look Profile sheets/ S Profile sheets, Tile design profile roof Sheets, Stud and Track, Lintels, Perforated sheets, Aluminum sheets, GI sheets, MS sheets, Checkered plates, Wire mesh, Metal roof tiles, Strut channels, Angles, Flashing, Gutter, Light engineering building material.

Metal Cutting Carbide Tips

Get Price Quote

We are working with a group of professionals who make special emphasis on the products packaging and ensure that the material is procured from the reliable sources only. We offer online and offline Payment Processing as per the needs of the customers; not just the transactions details, but we sternly keep the personal details confidential that is shared by our clients.

Section Pipe Bending Machine

Get Price Quote

1 Piece (MOQ)

A section pipe bending machine, also known as a section bender or profile bending machine, is used to bend pipes, tubes, and other metal profiles into curved shapes or arcs. This type of machine is primarily used in industries that require curved or circular sections of pipes or metal, such as construction, shipbuilding, and metal fabrication. Key Components: Rollers or Dies: These are the tools that the pipe or profile passes through. Typically, there are three rollers arranged in a pyramid or triangle, and they are adjustable to control the radius of the bend. Hydraulic or Electric Drive: The machine is powered either hydraulically or electrically to rotate the rollers and push the pipe through to achieve the desired bend. Frame: A strong, rigid structure that holds the rollers in place and supports the machine during the bending process. Control Panel: Used to set parameters such as roller positioning, speed, and bending angle. Adjustable Rollers: The position of the rollers can be adjusted depending on the size of the section being bent and the desired bend radius. Types of Section Pipe Bending Machines: Manual Section Bending Machine: Operated manually, often used for lighter materials and smaller projects. Hydraulic Section Bending Machine: Uses hydraulic power to bend larger or heavier sections of pipe or metal profiles. CNC Section Bending Machine: Computer-controlled for high precision and automation, used in large-scale production settings where repeatable accuracy is critical. Features: Multi-Directional Bending: Section benders can bend pipes in both vertical and horizontal planes, allowing for complex shapes and arcs. Bending Capacity: Can handle a wide variety of profile shapes, including round pipes, square tubes, rectangular sections, and other custom profiles. Variable Radius: By adjusting the rollers, operators can achieve different radii and bend angles to suit the specific needs of the project. Versatility: Section benders can work with various materials, such as steel, stainless steel, aluminum, and brass, making them versatile for different industries. Applications: Architectural Structures: For bending metal pipes into arches, railings, and decorative metalwork in buildings. Shipbuilding: Used to form curved metal sections required for ship hulls and frames. Automotive: For bending exhaust pipes, roll cages, and chassis components.Furniture Manufacturing: For creating curved metal furniture components like chair frames and tables. Structural Engineering: Used for making curved beams and sections used in construction projects, such as bridges, stadiums, and tunnels. Advantages: High Precision: Machines, especially CNC models, can produce very accurate bends without deforming the pipe or metal profile. Versatility: Can bend a variety of pipe sizes, profiles, and materials, making them useful in multiple industries. Efficient Bending: Hydraulic and CNC models can bend large sections quickly, improving productivity in large-scale projects. Reduced Material Waste: With precise control, section benders help reduce the risk of material wastage due to inaccurate bends or deformations. How It Works: The pipe or profile is placed between the three rollers. The two outer rollers push against the pipe while the middle roller exerts pressure, bending the pipe as it moves through the machine. By adjusting the distance between the rollers and controlling the force, the operator can control the radius and angle of the bend.

Welding Fixtures

6,000 Per Piece

1 Piece (MOQ)

Features Compact Design Its anti-corrosive Fine-finish Smooth working High durability Specifications Light weight Stainless Steel and superb material used Dimensional accuracy

Black Welding Helmet

Get Price Quote

1 piece (MOQ)

HDPE Pipe Making Machine

100,000 Per Piece

1 piece (MOQ)

Welding Fixture

Get Price Quote

Brown Ceramic Fire Welding Blanket

600 - 700 Per Piece

50 Piece (MOQ)

Muffler Robotic Welding Cell Fixture

1,800,000 - 2,000,000 Per Piece

2 Piece (MOQ)

Flux Cored Welding Wire

Get Price Quote

Metal Cored Flux Cored Wires for Hard facing:. Brand : Available in Reputed brands, Metal Cored Wires for Hard Facing (various hardnesses):260Hv,340 Hv, 450 Hv. Pakage Weight : 15 KG.

Welding Head Screen

320 - 360 Per piece

1 piece (MOQ)