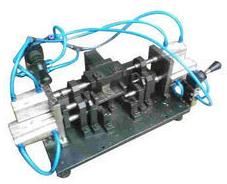

SFC Robotic Welding Fixture

810,000 - 1,500,000 Per Piece

1 Piece (MOQ)

Robotic Welding Fixtures

Get Price Quote

1 Piece (MOQ)

We are Manufacturer, Supplier, Exporter of Welding Fixture Lines, Welding Line Fixtures. Designing as well as in manufacturing of the welding fixtures. . our team is capable to handle all kind of welding fixtures. Started from the weld lines for two wheeler and now we have also stepped into the four wheeler. We are proud to say that we have worked for world wide renowned companies.

Best Deals from Welding Machinery

manual spot welding machine

Get Price Quote

As a reputed Manual Spot Welding Machine manufacturer, supplier and exporter, we at Weltronics supply a varied range ofManual Spot Welding Machines to our honorable clients spread across the globe. This manual spot welding machine passes high current through the electrodes towards the welding area at low voltage. When the manual spot welding machine cycles in a way it exerts pressure on the metal, than a joint gets formed coalescence occurs. Furthermore, the pressure is controlled by the air regulator, time is controlled by electronic circuit and current is controlled by transformer taps. Weltronics Manual Spot Welding machine is available for display and demo at our distributors or our facility at MIDC Bhosari, Pune, India.

Pneumatic Seam Welding Machine

Get Price Quote

We are offering pneumatic seam welding machine. Range : 50 to 200 kva special features: thyristor controlled electronic timer with electronic heat control, to give heavy duty high speed operation, providing smooth, stepless and accurate adjustment of the welding current. High quality roller bearings carrying the roller shafts, guaranteed longer-life of the roller heads. Leak proof joints at much lower costs than conventional welding.

Welding Fixtures

Get Price Quote

We understand that superior-grade raw materials are essential for the production of quality products. Thus, we maintain cordial association with reliable vendors of the market. With the complete help and support of our team members, we have strictly followed Warehouse Management System that helps us in loading and unloading the products efficiently.

Stainless Steel Welding Wire

200 Per Kilogram

500 Amp MIG Welding Machine

Get Price Quote

Stress relieving of welded mould

Get Price Quote

As per customers requirement Metric Ton (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: A. Sole authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. Offers SERVICES of vibratory stress relieving, anywhere in India, by Formula 62 VSR Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications like Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean-no discoloration, slag or scale 6. Single job weighing 500 kgs. To 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving 8. Process is environmentally friendly

Welding Machine Output Terminal

Get Price Quote

We are the leading supplier of this products.

Carbon Steel Plates

Get Price Quote

We offer Carbon Steel Plates. Being a client centric organization, we are engaged in offering a wide range of Carbon Steel Plates. Procured from renowned manufacturers our products are extensively acclaimed for their high functional efficiency and rough and tough performance. Our Carbon Steel Plates are manufactured from optimum quality components to ensure maximum durability and uninterrupted performance. One can avail these at market leading rates. Features: Rough and tough performance Durable Dimensional accuracy

Welded Wire Mesh Machine

Get Price Quote

Universal Type Seam Welder

Get Price Quote

Automatic Ear Loop Welding Machine

Get Price Quote

Welding Fixture

Get Price Quote

Automatic Mild Steel Welding Rotator

Get Price Quote

Infrared plastic welding machine

Get Price Quote

With Infrared plastic welding machine, we can save Electrical Power & Consumables cost. We can achieve hi Pull-load strength and leak resistance of welded parts. With Infrared plastic welding machine, we can save Electrical Power & Consumables cost. We can achieve hi Pull-load strength and leak resistance of welded parts.

industrial welding fixtures

Get Price Quote

Our organization has gained recognition as the affluent manufacturer and supplier of a wide range of Industrial Welding Fixtures. The products offered by us are designed to accurately locate and hold the component in their proper location for welding. Finest quality raw material is used to fabricate these fixtures in accordance with prevailing quality standards. Features: Corrosion resistance High tensile strength Efficiency

MIG welding machine

68,440 Per Piece

Self Aligning Rotator

Get Price Quote

Self Aligning Rotators automatically adjust the Roller Housings to accept any job diameters within the specified diameter range. These types of machines are generally used to cope with the increased production demands. The roller housings of this type of machine are hinged to the beds and open up automatically when a larger diameter job is introduced. In this type of rotator, each Roller bracket assembly has two separate roller assemblies, and this supports the job on a wider area. The final drive is given to all the 4-sets of rollers of the Drive Unit in special models, providing better traction to the job. However, in that case a de-clutching arrangement is provided to the top rollers, in order to protect the gear boxes, as when the job hits the top rollers first while loading, forcing it to rotate via. the self locking gear box. Both the rollers automatically get adjusted for all job diameters. Accepts complete range of job diameters in one setting. Center axis of job remain stable for all job diameters. Wide range of Job diameters and Load capacities. Most suitable for 'thin walled' shells of large diameters. 'Four roller' contacts gives superior 'slip free' traction for thin walled vessels. Proven reliability and higher productivity. Most accepted design for very busy fabrication shops. Ideal design for using in conjunction with Column & Boom. Better acceptability to ovality of vessels compared to other models.

stud welding guns

15,000 Per Piece