MIG Welding Contact Tips

Get Price Quote

SofterLower strength copper alloys contact tips tend to wear out quickly leading to downtime and reduced productivity. Worn tips are typically become oval and can cause an erratic arc from the random electrical connection and physical movement of the wire inside the worn tip. Contact tips precisely made from a wear-resistant copper alloy can give superior welding performance. Copper Beryllium tips have high wear resistance but are expensive to use.

esab welding machine

Get Price Quote

Co2 500 Amp and Tig 500 Amp/argon Welding.

Best Deals from Welding Machinery

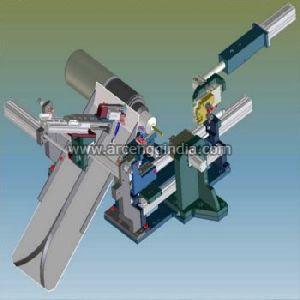

Manual MIG Welding Fixture

500,000 - 600,000 Per Piece

15 Piece (MOQ)

inverter welding machine

40,000 Per Piece

Welding Fixtures

Get Price Quote

The Welding Fixtures, delivered by us, have the robust structure which makes them durable. Buyers can approach us for acquiring top-of-the-line quality Welding Fixtures at coffer-friendly prices! Owing to the complete help of our dexterous staff, we present products that are certified as in conformance with the set norms.

Ball Screw

Get Price Quote

We make and supply of Ball Screws in Chakan, Maharashtra, India. Durable in nature, offered Ball Screw is damage resistant and available for buyers in different diameters. This screw is small in size and easy to install. Safe from damage by high pressure, offered screw is superior in quality and accurate in dimension. Moreover to this, screw has longer life.

Die Spotting Machine

Get Price Quote

The need for quick and reliable diemould tryout is constantly increasing because of the increasing number of new models and smaller batch quantities that are being produced in the automotive industry. In addition, forming processes have become complex, especially with the newer difficult materials. Therefore, it has become necessary to break-in and prove dies (new and reconditioned) well in advance of production start to save expensive production time. Electropneumatics’ Die Spotting and Tryout Presses have all the features needed to accurately simulate the actual manufacturing process for die prove-out. These presses can be used for die inspection, mould finishing and limited batchprototype production.

ppr pipe welding machine

3,700 Per Piece

TIG Welding Machine

Get Price Quote

Welding Fixtures

Get Price Quote

Mig Welding Torch Gas Diffuser

8 Per Piece

BIW Welding Fixture

45,000 - 900,000 Per Piece

1 Piece (MOQ)

Are you searching for ways to enhance your welding efficiency? Use our BIW Welding Fixture, a sturdy metal fixture intended for industrial uses. Sheena Enterprise is a leading BIW welding fixture manufacturer. What makes our fixture unique is its high functionality. It is meticulously crafted to perform precise and seamless welding operations. Featuring a stylish grey finish in brand-new condition that offers a touch of modernity and also ensures lifetime durability. It has a material-handling feature which makes it more versatile. You can use it for different welding tasks with ease and efficiency. Select Sheena Enterprises to get your hands on a reliable BIW welding fixture manufacturer. We are an industrial firm that strives to offer leading-edge solutions. Our fixture represents our devotion to quality. The item that you get is in line with the best industry standards for reliability and performance. With our fixture, you should expect enhanced welding productivity, which translates to cost savings and high output. Thus why go for mediocre when you can be exceptional? Consider Sheena Enterprises and see the difference in your welding operations with us.

Core Stack Welding Special Purpose Machine

Get Price Quote

1 Piece (MOQ)

spot welding fixtures

Get Price Quote

Spot Welding Fixtures are offered at cost effective prices to our clients. these fixtures for recognized clients such as Telco, primier auto and many more. Due to our advanced machinery and quality consciousness, Our range of welding fixtures assures high performance and less maintenance.

Welding Fixtures

6,000 Per Piece

1 Piece (MOQ)

Features Compact Design Its anti-corrosive Fine-finish Smooth working High durability Specifications Light weight Stainless Steel and superb material used Dimensional accuracy

Robotic Welding Fixtures

Get Price Quote

1 Piece (MOQ)

We are Manufacturer, Supplier, Exporter of Welding Fixture Lines, Welding Line Fixtures. Designing as well as in manufacturing of the welding fixtures. . our team is capable to handle all kind of welding fixtures. Started from the weld lines for two wheeler and now we have also stepped into the four wheeler. We are proud to say that we have worked for world wide renowned companies.

Multi Spot Welding Machine

Get Price Quote

1 Piece (MOQ)

Hot Plate Welding Machine

Get Price Quote

We are a prominent Manufacturer, Supplier and Exporter of Hot Plate Welding Machine which is mainly used for sealing application in car bumper, car-light, filter, pallet, vacuum cleaner etc. Hot plate welding utilizes a temperature controlled heat platen assembly with is introduced between the two parts to be assembled. The hot plate is typically flat, but can be shaped to match the profile of the components being welded. Hot plates are usually manufactured in aluminum or aluminum bronze. The component-holding fixtures are mounted on to the machine slides. The slides are designed to support the holding fixtures of the axial load without distorting the machine frame.

Welding Gas Regulator

800 - 900 Per piece

10 piece (MOQ)

Welding Glass

Get Price Quote

Offered by us is a superior quality assortment of Welding Black Glass, which is fabricated by making use of fine quality raw material at the reliable vendors premises that is outfitted with all the basic and advent technologies. Keeping safety concerns high, we make sure to quality test this range as per industry laid standards and norms that help in offering a useful range to the clients that serves their various applications of welding in a systematic manner.

CO2 Welding Machine

Get Price Quote

We are offering our clients with high quality and high performingMIG/CO2 welding machines at highly competitive prices. Wemanufacture, supply and export MIG/CO2 welding machines in various specifications to our clients from our facility in Bhosari, Pune, India.

Seam Welding Machine

1,299,000 - 1,300,000 Per Piece

400 Amp MIG Welding Machine

Get Price Quote

Stress relieving of welded mould

Get Price Quote

As per customers requirement Metric Ton (MOQ)

GURU NANAK STRESS RELIEVERS PVT. LTD.: A. Sole authorized DISTRIBUTOR in India for the 'Formula 62' Vibratory Stress Relief Equipment, manufactured by Stress Relief Engineering, California, USA, and marketed worldwide by Dreyfus Global Trade, LLC, New York, USA B. Offers SERVICES of vibratory stress relieving, anywhere in India, by Formula 62 VSR Equipment, USA, for: 1. Heavy Fabrications 2. Fabricated Structures 3. Weld Repaired Jobs 4. Castings 5. Stainless Steel 6. Aluminium 7. Machined components for maintaining dimensional stability 'Formula 62' Vibratory Stress Relief technology is useful in Industries like: 1. Aerospace 2. Automotive 3. Cement 4. Casting 5. Machine Building and Machining 6. Mining 7. Mold making 8. Power Generation 9. Railways 10. Ship Building 11. Sugar 12. Welding and Fabricators Advantages of 'Formula 62' Vibratory Stress Relief Equipment 1. Machine is compact & portable and can be taken to the place of stress relieving needs 2. Process time 15 to 90 minutes, depending on weight of the job 3. Used on wide variety of applications like Fabrications, Machined components, Castings, Shafts, Gears, weld repaired jobs 4. Does not disturb the metallurgical properties like hardness or tensile strength 5. Process is very clean-no discoloration, slag or scale 6. Single job weighing 500 kgs. To 150 tons can be stress relieved 7. Cost of vibratory stress relieving is approx 50% less than that of thermal stress relieving 8. Process is environmentally friendly

multi spot welder

Get Price Quote

Offers multi spot welder. Lot of automobile components, engineering hardware, white goods require to be spot welded. Multi spot welding machine is a composite technology machine to achieve higher production. One of the methods employ common transformer and welding in sequence one after another spot welding. It helps restrict connected power load. similarly a higher transformer capacity is installed and no. Of spot welding takes place simultaneously to further boost the production. The cage welding machine is one of the application in enviro industry to manufacturer wire filters(cages) it consists of feeding the, straight wires into the wire holders, wire rings (predetermined quantity) are placed in the centre limb. Initiating the cycle makes pair of electrode come down and weld two joints at a time. In sequence all the joints are welded. The power source (transformer) of smaller capacity (usually 30 50 kva) is installed. The auto function makes cage more out by predetermined pitch by pneumatic cylinder.

arc welding equipments

Get Price Quote

Arc welding equipments high edficiency and energy saving (Save energy be SM. compared with traditional wielding.Excellent Are.Start and Arc force, Pugh cooking strength.

Carbon Steel Plates

Get Price Quote

We offer Carbon Steel Plates. Being a client centric organization, we are engaged in offering a wide range of Carbon Steel Plates. Procured from renowned manufacturers our products are extensively acclaimed for their high functional efficiency and rough and tough performance. Our Carbon Steel Plates are manufactured from optimum quality components to ensure maximum durability and uninterrupted performance. One can avail these at market leading rates. Features: Rough and tough performance Durable Dimensional accuracy

Wear Parts

Get Price Quote

With our expertise in the industry, we are engaged in offering the best range of Wear Parts at very affordable rates. The range is 100% quality checked and you can rest assured us for the same. We along with our quality auditors make certain that even the raw material used go through varied stages of checking.

BIW Welding Fixture

Get Price Quote

We are a prominent Manufacturer and supplier of BIW Welding Fixture. The BIW Welding Fixture, which we offer is greatly appreciated for its precise design. With use of modular bases, units make the system versatile for any minor adaptations or any changes in design. High quality standard items are used in building fixtures, gives reliable and consistent in performance. Our BIW Welding Fixture is quality approved on different quality parameters like geometry, material, safety, and ergonomics and strictly adheres with industry laid quality benchmarks. One roof solution in design, development & manufacturing facilities allow us to deliver BIW Welding Fixture for CMM. We not only ensure the completion of project within deadline but also at the same time ensure the all aspects of project are as per customer requirement, meets to main concept.Our expert engineers take into considerations following construction details for manufacture product to meet exact requirements as per specification and customer demand. Ease in loading and unloading of panels Adjustments or shimming Proper selection of standards such as riser, cylinders, guide block, stoppers etc. as per application Optimization of unit Gun analysis Base Structure Ensure operator safety

Stud Welding Collet

Get Price Quote

1000 Piece (MOQ)