Laser Welding Machine

800,000 Per piece

1 piece (MOQ)

aluminum welding machine

175,000 - 250,000 Per piece

1 piece (MOQ)

Best Deals from Welding Machinery

Welding Robotic System

100,000 Per Piece

1 Piece (MOQ)

Manual Prototype Welding Fixture

29,600 - 30,000 Per Piece

1 Piece (MOQ)

Laser Welding Fixture

18,000 - 2,500,000 Per Piece

1 piece (MOQ)

Welding Machine

8,000 - 12,000 Per Piece

Section Pipe Bending Machine

Get Price Quote

1 Piece (MOQ)

A section pipe bending machine, also known as a section bender or profile bending machine, is used to bend pipes, tubes, and other metal profiles into curved shapes or arcs. This type of machine is primarily used in industries that require curved or circular sections of pipes or metal, such as construction, shipbuilding, and metal fabrication. Key Components: Rollers or Dies: These are the tools that the pipe or profile passes through. Typically, there are three rollers arranged in a pyramid or triangle, and they are adjustable to control the radius of the bend. Hydraulic or Electric Drive: The machine is powered either hydraulically or electrically to rotate the rollers and push the pipe through to achieve the desired bend. Frame: A strong, rigid structure that holds the rollers in place and supports the machine during the bending process. Control Panel: Used to set parameters such as roller positioning, speed, and bending angle. Adjustable Rollers: The position of the rollers can be adjusted depending on the size of the section being bent and the desired bend radius. Types of Section Pipe Bending Machines: Manual Section Bending Machine: Operated manually, often used for lighter materials and smaller projects. Hydraulic Section Bending Machine: Uses hydraulic power to bend larger or heavier sections of pipe or metal profiles. CNC Section Bending Machine: Computer-controlled for high precision and automation, used in large-scale production settings where repeatable accuracy is critical. Features: Multi-Directional Bending: Section benders can bend pipes in both vertical and horizontal planes, allowing for complex shapes and arcs. Bending Capacity: Can handle a wide variety of profile shapes, including round pipes, square tubes, rectangular sections, and other custom profiles. Variable Radius: By adjusting the rollers, operators can achieve different radii and bend angles to suit the specific needs of the project. Versatility: Section benders can work with various materials, such as steel, stainless steel, aluminum, and brass, making them versatile for different industries. Applications: Architectural Structures: For bending metal pipes into arches, railings, and decorative metalwork in buildings. Shipbuilding: Used to form curved metal sections required for ship hulls and frames. Automotive: For bending exhaust pipes, roll cages, and chassis components.Furniture Manufacturing: For creating curved metal furniture components like chair frames and tables. Structural Engineering: Used for making curved beams and sections used in construction projects, such as bridges, stadiums, and tunnels. Advantages: High Precision: Machines, especially CNC models, can produce very accurate bends without deforming the pipe or metal profile. Versatility: Can bend a variety of pipe sizes, profiles, and materials, making them useful in multiple industries. Efficient Bending: Hydraulic and CNC models can bend large sections quickly, improving productivity in large-scale projects. Reduced Material Waste: With precise control, section benders help reduce the risk of material wastage due to inaccurate bends or deformations. How It Works: The pipe or profile is placed between the three rollers. The two outer rollers push against the pipe while the middle roller exerts pressure, bending the pipe as it moves through the machine. By adjusting the distance between the rollers and controlling the force, the operator can control the radius and angle of the bend.

Brown Ceramic Fire Welding Blanket

600 - 700 Per Piece

50 Piece (MOQ)

QCW Laser Welding Machine Flexi Weld

2,200,000 Per piece

1 piece (MOQ)

The handheld laser welding machine combines quality of laser with flexibility of traditional welding to user’s advantage. The handheld laser welding machine is very easy to operate, which offers perfect welding seam without usage of any consumables at a fairly fast welding speed. The handheld laser welding machine can replace the traditional argon welding and electric welding. Features: High laser energy density, small thermal effect area, no deformation, less or minimal subsequent processing. Easy spot welding and continuous welding. Non-contact processing, stress free, noiseless, no pollution to the environment, Good welding quality, smooth and beautiful appearance, high welding speed, high strength. Weld strength and toughness equivalent or stronger than the base metal. Advantages: Fast welding speed, 2~10 times faster than traditional welding. The welding seam is smooth & beautiful, small taper, doesn’t need polish, save time. No deformation or welding scar, firm welding of the work piece. Laser welding has no consumables, low power consumption and long service life. Safe, easy operation and more environment friendly. Applications: The handheld laser welding machine can be used for welding stainless steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys, it can also be used for a variety of welding between different materials, such as: copper – brass, titanium – molybdenum, titanium – gold, nickel – copper and so on Handheld laser welding machine is widely used in the kitchen cabinets, staircase elevator, shelf, oven, stainless steel door, window guardrail, distribution box, medical equipment, communications equipment, battery manufacturing, craft gifts, household and other industries.

spot welding fixtures

Get Price Quote

Spot Welding Fixtures are offered at cost effective prices to our clients. these fixtures for recognized clients such as Telco, primier auto and many more. Due to our advanced machinery and quality consciousness, Our range of welding fixtures assures high performance and less maintenance.

Battery Tabs Welding Machine

6,000 - 100,000 Per Piece

1 Piece(s) (MOQ)

“S. S. Controls” is specialized in the manufacturing and exporting of high end Battery Tabs Welding Machine in the national as well as international markets. The Microspot Welding Machine for Capacitors made available by us is manufactured using highly advanced technology. Our Battery Spot Welding Machine is used in a number of applications like manufacturing of battery packs, lead welding of capacitor elements and welding of small parts like bulbs, thermocouple wires, wire harnesses etc. In addition to this, the company is counted as one of the reputed Battery Tabs Welding Machine Exporters in India. Specifications: Controller : Microprocessor Based Welding Controller, Our Model- 3W-OL / 15 For Precise Welding.Fully Synchronous, with Half Cycle Control. Welding Head : Pneumatically Operated Welding Head along with series Welding Assembly and adjustable platform to hold different sizes of battery cells. 100% Liner motion. No Electrode skid movement during welding. Thickness 0.03mm-0.6mm. Applications: Manufacturing of Battery Packs. Lead Welding of Capacitor Elements. Welding of Small parts like Bulbs, Thermocouple Wires, Wire Harnesses etc.

conveyor roller welding machine

275,000 - 475,000 Per no

Welding Torches

1,900 - 3,800 Per Piece

1 Piece (MOQ)

Robotic Welding Fixtures

Get Price Quote

1 Piece (MOQ)

We are Manufacturer, Supplier, Exporter of Welding Fixture Lines, Welding Line Fixtures. Designing as well as in manufacturing of the welding fixtures. . our team is capable to handle all kind of welding fixtures. Started from the weld lines for two wheeler and now we have also stepped into the four wheeler. We are proud to say that we have worked for world wide renowned companies.

Black Welding Helmet

Get Price Quote

1 piece (MOQ)

Hydraulic Operated Quill Feed Unit

Get Price Quote

A Hydraulic operated quill feed unit is not just an automatic drill press but much more than that. It is modular, automated machining which usually has two or more axes of motion. One us the linear feed and the other one is the spindle rotation. This mechanism feed can be hydraulic, mechanical or pneumatic and can extend to the spindle in the quill. The feed unit can do everything starting from basic drilling to tapping and more exotic application such as a combination of reaming and drilling, twisting and even thread rolling. If you are in search of a feed unit get it from us at Paston Machines PVT. Ltd. We are the best Hydraulic Operated Quill Feed Unit Manufacturer. Our products are the best and long-lasting. For any kind of queries and questions related to our products and services, you can ask us directly through the help link or by directly calling us.

Welding Positioner

Get Price Quote

1 Piece (MOQ)

After the goods are sternly examined by the experts, the picking, checking, labeling and packing commences in the substantial warehouse. Sprawling over a large area, we ensure that the goods are packed with utmost proficiency. The assistance of our quality auditors helps us in acquiring quality-approved raw materials from the certified vendors. Thus, we ensure that our products are of unmatched quality. Product Range : 2 ton to 230 ton job handling capability

metal building material

Get Price Quote

200 Meter (MOQ)

Roof sheets, Cladding materials, Metal building materials, Insulated metal Roof and wall sandwich panels, Z & C Purlins, Decking sheets, Corrugated sheets, Box Profile sheets/ Trapezoidal sheets, Wave look Profile sheets/ S Profile sheets, Tile design profile roof Sheets, Stud and Track, Lintels, Perforated sheets, Aluminum sheets, GI sheets, MS sheets, Checkered plates, Wire mesh, Metal roof tiles, Strut channels, Angles, Flashing, Gutter, Light engineering building material.

Core Stack Welding Special Purpose Machine

Get Price Quote

1 Piece (MOQ)

Hdpe Pipe Making Machine

100,000 Per Piece

1 piece (MOQ)

Butt Weld Valve Testing Machine

4,025,000 Per Piece

1 Piece (MOQ)

Metal Cutting Carbide Tips

Get Price Quote

We are working with a group of professionals who make special emphasis on the products packaging and ensure that the material is procured from the reliable sources only. We offer online and offline Payment Processing as per the needs of the customers; not just the transactions details, but we sternly keep the personal details confidential that is shared by our clients.

Galvanometer Scanning Laser Welding Machine

5 Per Piece

1 Piece(s) (MOQ)

Anti Spatter Spray

90 - 120 Per Bottle

125 Bottle (MOQ)

We are providing Anti Silicone Spatter Spray, which stops spatter from sticking to the gas nozzles and the area next to the weld. It is an aerosol, which provides perfect surface protection during welding. This spray is nonflammable and is mostly used in industries. The silicone, or a comparable component, which is often a petroleum-based or water-based solvent, is present in Anti Silicone Spatter Spray to keep the spatter from adhering.

Welding Fixture

Get Price Quote

Pneumatic Seam Welding Machine

Get Price Quote

We are offering pneumatic seam welding machine. Range : 50 to 200 kva special features: thyristor controlled electronic timer with electronic heat control, to give heavy duty high speed operation, providing smooth, stepless and accurate adjustment of the welding current. High quality roller bearings carrying the roller shafts, guaranteed longer-life of the roller heads. Leak proof joints at much lower costs than conventional welding.

Semi Automatic Ultrasonic Plastic Welding Machine

280,000 Per Set

1 Set(s) (MOQ)

We are supplier and exporter of this product.

BIW Welding Fixture

Get Price Quote

We are a prominent Manufacturer and supplier of BIW Welding Fixture. The BIW Welding Fixture, which we offer is greatly appreciated for its precise design. With use of modular bases, units make the system versatile for any minor adaptations or any changes in design. High quality standard items are used in building fixtures, gives reliable and consistent in performance. Our BIW Welding Fixture is quality approved on different quality parameters like geometry, material, safety, and ergonomics and strictly adheres with industry laid quality benchmarks. One roof solution in design, development & manufacturing facilities allow us to deliver BIW Welding Fixture for CMM. We not only ensure the completion of project within deadline but also at the same time ensure the all aspects of project are as per customer requirement, meets to main concept.Our expert engineers take into considerations following construction details for manufacture product to meet exact requirements as per specification and customer demand. Ease in loading and unloading of panels Adjustments or shimming Proper selection of standards such as riser, cylinders, guide block, stoppers etc. as per application Optimization of unit Gun analysis Base Structure Ensure operator safety

Welding Screen

Get Price Quote

Welding Helmet is made of Thermo Plastic Resin material. It keeps it light in weight, maintaining good mechanical strength and is fitted with LIFTING WINDOW for fixing filter glasses (Dark & Clear). This window can be lifted upwards and in this way Dark Glass will go upward to give clear vision on the job for any kind of inspection or deslaging the weld. It avoids frequent lifting of whole helmet and so gives the Welder a very smooth and comfortable operation of his work. The head ring fitting (belt) is unbreakable and to give good tilting on forehead and head. The fitting points (knobs) of the belt with the main body of the Screen are so designed to give good tilting operation of the whole screen giving it proper positioning at any angle which is required by a Welder.

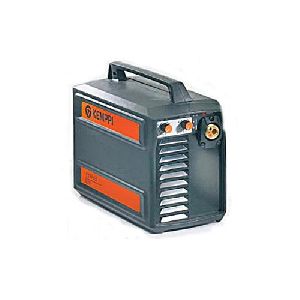

Mig Mag Welding Machine

Get Price Quote