Self Centering Rotator

Get Price Quote

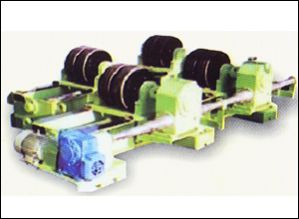

The construction of this type is similar to Conventional Type except that this model has a provision to slide the Roller Brackets over the Base Frame equally in both directions through a lead screw having LH & RH Threads. Unlike in Conventional Type the Roller Brackets in Self Centering Type is not bolted on the base frame. The rotation of lead screw can either be Manual or Motorized (Optional). The Technical Specifications are same as Conventional Type. Salient Features Low investment cost. Ideal version to start with new fabrication line. Most suitable for small and heavy fabrication shops. Simple & Sturdy design. Proven reliability. Accepts wide range of Job diameters.

Automatic Mild Steel Welding Rotator

Get Price Quote

Best Deals from Welding Rotator

Conventional Welding Rotator

Get Price Quote

Welding Rotator

Get Price Quote

With our rich experience and in-depth knowledge, we are engrossed in providing a wide array of Welding Rotator. Our provided collection is available in diverse technical specifications as per customers’ choices. Our standard Rotators consists of Drive Unit and Idler Unit. The frame and rollers brackets our fabricated rollers heavy section, stress relieved and precision machined Overload disc to protect polyurethane roller Variable surface speed from 75 to 1500 mmm or higher ratio and controlled through AC Variable Frequency Drives. For precision movement encoder feedbacks are provided on case to case basis Forward and Reserve rotation along with inching facility on panel Product Details: Robust construction Easy to operate Low maintenance Long life Precisely designed Resistant against corrosion

Automatic Mild Steel Welding Rotator

Get Price Quote

Self Centering Rotator

Get Price Quote

We hold normally 2000 to 3000 tonnes of steel in our works to ensure on time delivery to clients. The material is confirmed prior to manufacturing with all required Chemical, Physical and ultrasonic tests by our Quality Control department. We hold a strong setup of raw material in various thickness ranging from 5 mm to 250 mm thickness of reputed mill. We also have full fledged facility of CNC profile cutting with modern machines and equipment for better quality.

Conventional Rotators

Get Price Quote

These comprise basically two sets of rollers (1 drive + 1 idler) which are adjustable either manually( connecting shafts) across the frames or through lead-screw ( with motorized or through ratchet) when changing from one diameter to another.

Welding Rotators

Get Price Quote

Welding Rotators, Welding Machine, Welding Column, Welding Positioners

Mild Steel Welding Rotator

87,500 Per Ton

Welding Rotator

Get Price Quote

We are the leading supplier of this products.

Welding Rotators

Get Price Quote

We are offering welding rotators are very essential equipments for heavy and light fabrication shop. They are mainly used to rotate or position the cylindrical jobs for circumferential welding (tig mig sub arc) or for intricate assemblies. The machine consists of 1 no. Drive unit and 1 no. Idler unit and control panel with pendant.

Self Aligning Type Welding Rotators

Get Price Quote

Self Aligning Type Welding Rotators, Propeller Shaft Welding Machine

Welding turning roll

Get Price Quote

Welding turning roll, Auto Tig Feeder Welder, brazing equipment

Welding Rotators

Get Price Quote

Welding Rotators, beam welding line, Hydraulic Scissors Lift

Welding Rotator

Get Price Quote

Welding Rotator, Lightweight Crane, Hoist, Manipulators

Self Centering Rotator

Get Price Quote

Self Centering Rotator, Chemical Dosing Plant, Self Aligning Rotator