Wood Chip Briquetting Machine

Get Price Quote

Storage of chips and recovery of precious metal cutting fluid is of primary concern in this industry. Traditionally hydraulic presses are used to recover the fluid by compressing the chips in briquettes or tablets. The traditional design has a hydraulic cylinder, which presses the chips in a mould. But this design is costly and consumes lot of space and power. Veeraja has designed a new product with high production capacity but still keeping the price and space requirement low. Features & Benefits Compact design High production capacity Separate loading compression and ejection ports Low running cost Applications Our experts will always be happy to help you select proper product / combination of product for your industry application. Steel Grinding Washing Machine Gun Drilling Tube mill

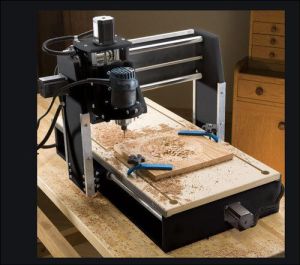

Cnc Wood Carving Machine

375,000 Per Piece

Wood carving cnc carving machine.

Best Deals from Wood Working Machines

Wood Carving Machine

450,000 - 850,000 Per piece

1 piece (MOQ)

Post Forming Machine

Get Price Quote

1. First Postforming machine to be manufactured in India 2. More than 500 users across India and abroad 3. PLC Programmed machine for fully automatic operation 4. Simple yet robust design for trouble free performance over prolonged period 5. Available in Three Phase as well as Single Phase model Post Forming Machine is chiefly used for bonding of flexible laminate with molded edge of the particle board / MDF board or Ply. Bonding can be full round, half round or bull nose type. We provide two standard modes of operation namely, manual mode and auto mode. In manual mode, all the functions are carried as per the switches pressed by the operator. This is mainly required for bull nose type of job setting. Our Post Forming Machine is operated by the Programmable Logic Controller (PLC). Normally our first program is set for the full round job and second program is for the half round job. The type of job can be selected as per the requirement. The remaining seven programs out of the nine can be customized as per the job requirement. We teach how to program the machine when we come for the installation. When the cycle is started in auto mode, all the operations are carried out in series like clamping, the heater bar forward, and slowly it covers the entire surface to be manufactured. Finally the release of heater bar and de-clamping takes place and the machine cycle comes to the initial/start position. Post Forming Machine Salient Features: 1. Three (3) clamping cylinders for better work piece holding. 2. Eight (8) cylinders for heater bar operation to ensure uniform pressure. 3. Short job / Long job selection. 4. Full round / Half round setting. 5. Ground and hard chrome plated heater bar for smooth operation and long life. 6. PLC Programmed machine for fully automatic operation. 7. 9 standard programs can be stored. 8. Reputed brand raw material used for manufacturing. 9. Personal attention while manufacturing the machine. 10. Special heater construction for uniform heating. 11. Separate control panel for ease of use. 12. Standard electric circuit. Post Forming Machine: Technical Specifications Max. Workpiece length:2400 mm Max. Work piece length(Recommended): 600 mm Min. Work piece width:160 mm Max. Work piece thickness: 100 mm Min. Work piece length:16 mm Connected load: 3 KW Electric Supply: 3 Phase 415 V AC Other voltages optional Compressed Air Requirement: 30 LPM at 6 bar (Specifications are subject to change without prior notice.)

Post Forming Machine

Get Price Quote

Post Forming Machine, laminate testing equipment

Multi Operation on One Machine bed

Get Price Quote

Multi Operation on One Machine bed, Rolling Machines

Post Forming Machine

Get Price Quote

Post Forming Machine, Wood Working Machinery, Hot Press

Image Carving Machine

Get Price Quote

Image Carving Machine, Trade Outlet Service, Event Image Design Service

Woodworking Machine

Get Price Quote

Lathe Machine, industrial drilling machine, Industrial Lathe Machine