Paper Pallets

Paper pallets are not only sturdy and lightweight but also eco-friendly. Despite of wooden pallets paper pallets are vermin free, and 100% hygienic. Paper pallets are basically invented in early 1940s. when there was a huge issue about return trip cost. Returning of wooden pallet was equally charged by transporters as regular fares. Paper pallets resolved the issue by just recycling the pallets after its use. Cost effective and perfect solution found. But paper has certain limitations. Today, we have successfully overcome all limitations. Paper pallets are more durable, water resistant and lightweight. Paper pallets have loading capacity from 300kg to 1200kg. Customs departments from most of the countries don’t allow metals and wood components in shipment as packaging material.

...more

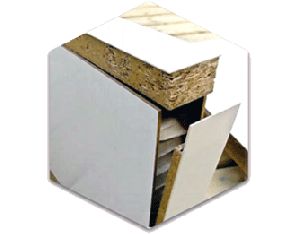

Honeycomb Corner and Edge

500 Piece (MOQ)

Honeycomb Paper Pallet

Paper pallets are not only sturdy and lightweight but also eco-friendly. Despite of wooden pallets paper pallets are vermin free, and 100% hygienic.Paper pallets are more durable, water resistant and lightweight. Paper pallets have loading capacity from 300kg to 1200kg. Customs departments from most of the countries don’t allow metals and wood components in shipment as packaging material.

Capacity : 300kg to 1200kg

...more

honeycomb paper board

Honeycomb paper boards are made up of kraft paper which is mainly used as raw material for packaging purposes. Honeycomb paper boards are available in variety of thicknesses and therefore mainly used as buffer in boxes. Honeycomb boards are modified to fill the void spaces in box. This will ensure that product will not shake or misplace from its place inside the box.

Thickness : 20, 25, 30, 35, 40, 45, 50, 60 (mm)

...more

Honeycomb Panels

Honeycomb Pallets

700 Per Pallet

Honeycomb Furniture

Features : High strength,Laminated with water resistant layer,Durable,100% Eco-Friendly

Honeycomb Fitments

500 Piece (MOQ)

Honeycomb Corner, Edge Protectors

Detailed Description :“Honeycomb Corner Support & Edge Protectors” are moulded from Honeycomb Boards, the corner supports ensures Damage proof and protected transport. Unlike other conventional supports, Honeycomb Support are lightweight very easy to install and apply. Support are folded on creasing line and ready.Honeycomb support are available in various size and thicknesses. There is an advance version of fitments which can bear up to 50 Kg. weight per square inch. Honeycomb supports mostly preferred by exporters and MNCs. Support leave no marks on proucts. This preference is due to its simple yet robust design, easy to apply and 100% bio-degradability. Working Principle:Honeycomb are made from honeycomb boards or panels. The strength of any support lies in its core. Smaller is the core greater is the strength. Support are designed to provide sturdy grip to product packed in the box. V-cuts are applied to board for getting shape of Support. The top and bottoms paper with high Bursting factor is durable enough to take stress during bending and intire shipment process. If customer demands for high pressure strength node size 6mm will be more suitable. In case customer need more cushioning the node size 10 mm is preferred. Features:• Cost effective - Easy to install, less initial cost, less labour• Do not leave any mark on product• Wide range of dimensions and pressure loading capacitiesApplications of Honeycomb Edge and Corner SupportsControl Units, Electronic Components, tempered Glass panels, Speaker systems, automobile spares, Furniture assembly parts, etc. Advantages of Honeycomb Edge and Corner Supports :• It is the best substitute for thermocol & Foam sheet• Customized design ensures the exact fitting of product.• It is easy and safe to handle and use.• An effective material and method to discharge our responsibility towards the protection of our environment and earth.• Special offers for Packaging Industries.

...more

Honey comb Core Door Fillings

70 Per Square Meter

Features : High compression strength,Compact design,Can Endure in 2200C and Suitable for all types of Power coating Furnaces

Thickness : 20mm, 25mm, 42mm, 45 mm, 50 mm, 55 mm

honeycomb boards

Detailed Description : Honeycomb paper boards are made up of kraft paper which is mainly used as raw material for packaging purposes. Honeycomb paper boards are available in variety of thicknesses and therefore mainly used as buffer in boxes. Honeycomb boards are modified to fill the void spaces in box. This will ensure that product will not shake or misplace from its place inside the box. Honeycomb paper board also used as firm base inside the box. High pressure strength is one of the advantage of honeycomb boards. The major advantage of honeycomb board is it’s easy to cut-paste process. Unlike the thermocol, honeycomb boards can be customized with very low cost. Working Principle :The honeycomb board is nothing but the layer of paper and honeycomb core. The main strength is in core, Honeycomb core is flexible and can be stretched up to 15 times it’s original size.The top and bottom papers are also called as “outliners”. Outliners are useful to keep honeycomb core at it’s position, making it straight and stable. Sandwiching mainly involves gluing and heat treatment. Features:• High Strength• Durable• Approved By All Countries Over The Globe• Easy To Cut And Paste Applications of Honeycomb Boards :The honeycomb boards are used as buffers, separators, cushions, fitments, base, support inside the box. We can also use honeycomb boards to make display panels for more info. Please visit Honeycomb panels. Advantages of Honeycomb Board :• It is the best substitute for Foam & Thermocol (EPS)• Depending upon the applications, these boards are available in a variety of forms such as Void Fillers, Dunnage• These boards guarantee the transport of almost any product without damage.• The boards have excellent separating, stabilising and protecting characteristics. They are easy to handle and comply with high levels of energy absorption needs.• Paper honeycomb boards are also made of recycled paper and are 100% recyclable.• Special offers for Packaging Industries.

...more

Carton Box

40 - 65 Per Kilogram

5 ply for smaller weight capacity boxes and 7 ply for higher capacity boxes or products packaging is preferred. In few cases 9 ply is also suggested to gain more strength.Export cartons are produced with Higher Busrting Strength to ensure safe shipment even if stacking is done during material loading.

Type : Export Cartons

Shape : Rectangular, Square

Application : Food Packaging, Goods Packaging

Feature : Durable, Eco Friendly, Heat Resistant, Impeccable Finish, Light Weight, Recyclable

Pattern : Plain

Condition : New, Used

...more

Corrugated Paper Sheets

YOJ® pack-kraft was established by a technocrat with a mission to develop eco-friendly alternatives in corrugated packaging solutions. Accordingly, the first manufacturing facility was set up and made operational at Pune in India in the year 2000. Ever since then, the company and its products are creating wider applications and finding greater acceptance by the user industries and the market. In keeping with the pursuit and the potential for developing and providing environmentally complying products.

...more

Corrugated Paper Pallets

Highly preferred for Air Shipments due to High Strength To Weight ratio • Equipped with Water Resistant Coating making suitable for Sea-Shipments too. • Approved design by all Countries over the Globe. As per norms few countries avoid shipment with polythene, PU Foam, wood and metal components in packaging material. For those countries Paper Pallets are best option to ship with. • Greater Stability with robust design during shipment • Designed as per EURO Standards; Additional support at Forklift spaces, 4 Way Lifting possible.

...moreBe first to Rate

Rate ThisOpening Hours