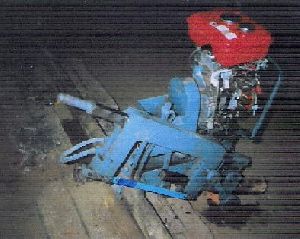

WELD TRIMMER WITH POWER PACK

By alumino thermic welding process, the rail joint is made by pouring molten metal in the rail gap. The excess metal over the rail head is required to the chipped off. This is done by putting the Weld Trimmer over the rail head while it is hot. This hydraulic rail sharing machine moves the two blades of the trimmer inwards and on completion of trimming; the blades are brought back outwards.The machine is mounted on monowheel trolley which allows the machine to be carried on rails or on ground. The clamp provided with the machine is universally adjustable for any section of rail to ensure proper completion of the job to be performed. FEATURES OF THE MACHINE Substantial reduction in the grinding time as well as in the block time required for welding. Increased life of the joint. Accurate rail profile cutting. Reduction in the risk of manual operation due to machanised trimming. User friendly machine. Rugged and robust construction.

...more

Rail Profile Weld Grinder

The rail head joint after trimming operation is subjected to grinding or reprofiling. The Rail Profile Weld Grinder run by the petrol powered portable power generator operates the grinder which can be adjusted over the rail head as per inclination required.This machine is robust and user friendly. ADVANTAGE Considerable time in saved besides achieving perfection & safety in operation.

...more

RAIL DRILING MACHINE

The machine is used for drilling holes on the rail web for fish plates. Its works by engine which makes the machine suitable for working at any site without requirement of external power. The machine is mounted on monowheel trolley which allows the machine to be carried on rails or on ground. The clamp provided with the machine is universally adjustable for any section of rail to ensure drilling of the hole centrally. FEATURES OF MACHINE Overall weight of the machine 60 Kg Men required for operation TWO Operating time 3-5 Minutes 6-8 Tolerance of holes +0.7mm

...more

RAIL CUTTING HEXAU MACHINE

The Machine is used to cut rails. It works by engine which makes the machine suitable for working at any site without requirement of external power. The machine is mounted on monowheel trolley which allows the machine to be carried on rails or on ground. The clamp provided with the machine is universally adjustable for any section of rail to ensure proper completion of the job to be performed. The machine fitted with universal clamp which ensures a perfect vertical cut of the rail. FEATURES OF MACHINE Overall weight of the machine 70 Kg Men required for operation TWO Operating time 8-20 Minutes (Depending On Rail Section)

...more

PREFABRICATED MOULD

For joining rail by thermic welding process , moulds are used which provide cavity around the rail in moulds while welding. These mould are prefabricated in three parts. While welding its fixed at rail ends which is to be welded . Liquid metal after thermic reaction in crucible is poured in this mould for joining rails

...more

LONG LIFE CRUCIBLES

The long life Crucibles are made of thin Mild Steel (M.S) shell. A charge of magnesite is separately manufactured and placed in the shell.The crucible has a life of approx 35-40 joints. After Long use,the crucible charge is discarded and a new charge is placed into the shell. The long life lining is totally inert and only requires the removal of slag only once during the life of Crucible. This helps to increase the life of lining because mechanical damage is not inflicted by frequent slag removal.

...more

compressed air petrol preheating equipment

The rail ends are required to be preheated for short period before welding. The equipment runs on petrol, hence easy mobility and considerable time saving is achieved as it takes only 4 to 5 min time. The machine is mounted on monowheel trolley which allows the machine to be carried on rails or on ground.

...more

AUTO TAPPING THIMBLE

1 - 5 Per Piece

In the Alumino Thermic process, the molten metal in the crucible has to be released into the mould for executing a weld joints, Earlier, this release was being made by manual tapping, however, with the Automatic Tapping Thimble (Auto- thimble) the tapping in done within a specified time at a predetermined temperature.

Type : Auto Tapping Thimble

Application : Industrial Use

Condition : New

Country of Origin : India

...moreBe first to Rate

Rate ThisOpening Hours