Semi Automatic Bottle Filling Machine

1,200,000 Per Set

1 Set(s) (MOQ)

PLC Operated Pulse Filling System Viscos, Sticky, semi Liquid and Liquid Material Packing Semi Automatic Bottle Filling Machine or Jar Feeding and Filling System High Accuracy at high speed packaging Can be attached to any packing line Large range of filling � No Mechanical Settings for Volume Adjustment � All Software Control Description Our PLC based Bottle and JAR filling machines range in size from portable table top machines to industrial size liquid packaging systems. We have avoided most mechanical setting in our machine so that the changing of filling volume and material is became fast and easy. Our packing machines has lot of option for various material and capacities. Our each machine has large range of feeling volume rather than other mechanical machines. We use high quality components and equipment for get the real industrial output. Our machines manufactured as per international industrial standards.

Bottle Packing Machine

Get Price Quote

Best Deals from Bottle Making Machine

Soda Bottle Filling Machine

Get Price Quote

We are counted amidst the prominent Manufacturers, Exporters and Suppliers of Soda Bottle Filling Machine. Advanced technology and graded material are used to construct the Soda Bottle Filling Machine. Extensively used in the beverage industry, the Soda Bottle Filling Machine automatically fills the soda bottles without any hassle and that too in a much less time. We offer rigidly constructed, smoothly working and cost effective Soda Bottle Filling Machine to the clients in customized specifications.

40 Bpm Bottle Filling Machine

Get Price Quote

We are offering 40 bpm bottle filling,rinse,capping machine in s.s automatic.

Plastic Bottle Making Machine

Get Price Quote

Plastic Bottle Making Machine Approx By keeping track with the market development, we are offering optimum quality Plastic Bottle Making Machine. Our provided machine is manufactured by a team of our adept professionals utilizing quality approved raw material and advanced technology. Our offered machine is widely appreciated by our prestigious clients for its precise design and durability. The offered machine can also be availed in various sizes, designs and other related specifications.

Soft Drink Bottle Packaging Machine

255,000 Per Piece

1 Piece (MOQ)

Linear Bottle Washing Machine

Get Price Quote

1 Piece (MOQ)

we are offering linear bottle washing machine. description:- automatic linear bottle washing machine is suitable to wash glass bottles. machine equipped with six washing stations can be interchangeable as per specific customer’s requirements. this linear bottle washer provides 3 water wash & 3 air wash for positive & pressurizing washes of bottles. all contact parts made from stainless steel 316 and non-contact parts made from stainless steel 304 materials. bottle invert into neck down position and nozzles enters into bottle during washing cycle to meet gmp requirements. automatic linear bottle washing machine is ideal and economic choice for online sterile vial filling line. machine is having uses in pharmaceutical, cosmetic, food, chemical & allied industries. salient features:- * a complete cgmp model * all contact parts are made from high quality stainless steel 316l and argon arc welded * all exposed parts are made from stainless steel 304hard chrome platedbrass for corrosion free long life. * the unit built on s.s. square pipe frame and totally encompassed with s.s. coverings * washing section is totally covered with acrylic cabinet. * “no container - no washing” system. * “no washing - no water supply” system. * quick change over with minimum use of tools. * variable ac frequency drive for speed adjustment. * low water consumption. * digital counter for counting production output. * fixed top nozzles at each washing station ensures external washing of vialsbottles at the same time of internal washing. * flow of washing medias stop during the indexing of chain saves utilities. * easily cleanable & inter changing facility. process operation:- containers feed from the de-cartooning station are received on an in feed turn table. an in feed worm inverts container to neck down position and feeds them through a specially designed indexing device. the device carries the container forward and stops. nozzles carrier enters into the container and activities the jet of waterair. the airwater flow is deactivated after the washing cycle is over. device indexes the vialsbottles for next wash. a separate pumping station gives the right quantum of water at the desired pressure. washed containers are again inverted to neck upward position to collect in out-feed traydirectly feed to tunnel. washing cycle:- 1st wash recycled water 2nd wash purified air 3rd wash dm water 4th wash dm water 5th wash purified air 6th wash distilled water (wfi)

bottle shrink wrapping machine

240,000 Per Piece

Horizontal Pet Preform Plastic Injection Moulding Machine

Get Price Quote

We are offering horizontal pet preform plastic injection moulding machine. Standard features : - high production capacity with high power saving. - automatic mould height adjustment. - hydraulic, electrical, mechanical safeties. - large tie bar distance & platen area. - user friendly controls cause easier to operate. - auto lubrication system with grease. - low noising level - mould safety system - low maintenance cost electrical accessories : - plc controller b & r system or streamline controls pvt ltd. - electric wiring with finolex wire r.r cable. - electric accessories:tcselectron. - temp. Controller - servo motor : phase motion (tde macno),germany. - drives : tde make in italy - linear scale:gefran. - hydraulic injector through the linear scale mechanical accessories : - hydraulic valve & pump yuken india ltd. Or rexorth bosch ltd. - stainless steel material hopper with magnet - hard chrome platen tie barwith double grinding and micro finishing. - mould plate again casting sg iron casting, word class. - en-41b gas nitride screw barrel withmixing zone. - radial piston hydro motor made inintermation. - phosphors bronze bushing. - refilling screw rpm counting system. - 5 stage injection pressure system.

Bottle Filling and Capping Machine

Get Price Quote

1 Piece (MOQ)

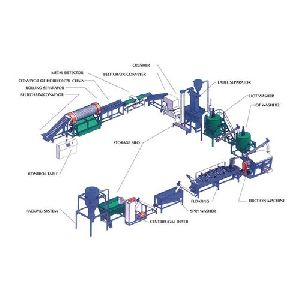

Pet Bottle Recycling Machine

7,200,000 Per Piece

pet bottle washing machine

Get Price Quote

Boretech China, year 2011, fully automatic, 1500 kghr capacity, pet bottles recycling washing line. For conversion pet bottles scrap into pet flakes. Plant is in excellent condition having environment friendly process. Plant is having complete line from pre washing, bale feeder conveyor, hot and turbo washing, dryer, scrapper to pet storage and up to fully automatic packing system. PLC operated panels for controlling the system

bottle packaging machines

200,000 - 5,000,000 Per Set

Use water and soft drinks filling and packing machine

PET Bottle Filling Machine

110,000 Per Piece

1 Piece (MOQ)

Automatic Premium Bottle Filling Machine

Get Price Quote

Semi Automatic PET Blow Molding Machine

Get Price Quote

Versatile Machine ( 20 ml to 5000 ml neck size 19 mm to 150 mm ) These versatile machines can be used to manufacture different kinds of bottles with neck diameter of 20 mm to 150 mm. The bottle / jar capacity can range from 40 ml up until 5000 ml. Mould Clamping Hydraulic mould clamping system to enhance power efficiency. It saves air consumption and hence reduces production cost. Unique mechanical lock system for positive locking. Heating Close loop heating system and auto chamber temperature control (to compensate variation in preform heating due to ambient temperature). Optional auto preform temperature control. Positioning of heaters is better, ensuring faster and simpler heating. Individual heater position is adjustable in both axes to achieve optimum heating. Air ventilation with controllable venting in heating chamber (for better heat penetration control). Start-stop index type oven to minimize variation in temperature of both preforms coming out of chamber at a time. Product Range Versatile range to produce 40 ml to 5000 ml bottle / jar. Neck diameter ranging from 20 mm to 120 mm. Due to hydraulic operations, mould can be stopped where required. In case of small diameter bottles, this increases production rate and reduces production cost. Safety Two hand operations (till mould close function is complete) to prevent accidents. ELCB in main supply for protection against electric shock. Individual MCBs for all heaters.

Complete Tablet Bottle Packing Lines Machine

Get Price Quote

Complete Tablet Bottle Packing Lines - 120 BPM SPEED UNSCRAMBLER-120 - Complete Tablet Bottle Packing Lines - Automatic Unscrambler for Round Bottles The Automatic Bottle Unscrambler is suitable to connect with any machine for uninterrupted feeding of bottles with speed upto 120 Bottles per minute depending on Bottle diameter and height. Unscrambler transfer bottles directly from Loading Hopper to infeed conveyor of any machine in vertical position. Machine is mainly suitable to connect with Bottle Air Jet cleaning machine shown in the layout for used in Bottle packing line. Machine can be used for feeding of Plastic or PET Bottles, Jars etc. Machine suitable for use on products like Dry Syrups, and Bulk Packing of Tables and Capsules. Machine in Stainless Steel Finish with all contact parts in SS316 and Nylon Materials. Machine also having overload clutch system to prevent jamming during the operation. The manifold comprises of inner nozzles which jets compressed air in the bottle and an outer socket, which cover the mouth of the bottle and is connected to an exhaust, ensures perfect cleaning. SPECIAL FEATURES : Fully Stainless Steel Finish Simple Change over for different size of Bottles Overload Clutch for Jamming A.C. Variable Frequency Drive System.

Bottle Washing Machine

Get Price Quote

We offer Bottle Washing Machine. Rotary Vial Washing Machine Model ARVW-120 suitable for 2 ml to 30 ml Vials, with in built 2nos. S.S. Tank and 2nos. S.S. Centrifugal Pumps. Fully automatic machine with Mechanical loading platform and vertical collection at outlet. Machine has a series of 13 Jets in each wash to clean each vial with maximum timing unlike other models, which have one nozzle per vial.

Aluminium Bottle Making Machine

Get Price Quote

1 Piece(s) (MOQ)

We are offering aluminium bottle making machine. These machines enable to manufacture bottles of different sizes ranging from 15-25 ml. The bottles are used for storing different material such as: • pesticide • perfumery • medicine • beverage the machine is equipped with motor used for driving, indexing unit, tooling in varied sizes for different bottles. We manufacture different sizes of combination machines like: • 15 to 25 ml • 50 to 100 ml • 250-500 ml • 500 ml dia 74 mm to 1 liter dia 89 mm • 1 liter to 1.5 liter.