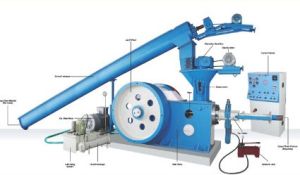

Biomass Briquetting Plant (Jumbo - 90)

Get Price Quote

The Briquetting Plant is a ram type press designed for continuous heavy-duty operation with two load wheels. One of the load wheels acts as a pulley, and driven by the main motor through a flat belt. Forced lubrication is provided by oil lubrication system which gives a longer life to the bushes.Dry agro - forestry waste as a raw material is fed through the screw conveyor to Kupy by means of vertical screws, with its own-geared motor. It pre-compress and forces the material downward into the feeder box. From the feeder box the material is forced by the Ram through Taper die and due to high pressure & heat, raw material (Biomass) is converted into solid cylindrical briquettes. Finally finished briquettes come out from die holder and passes through natural cooling lines.During Process lignin content in the raw material (Biomass) is transformed into liquid form & acts as a natural binder. Therefore it is called the Binder less Technology. Jumbo-90 is flagship model in Biomass briquetting industries. Jumbo-90 gives more production and minimum process cost per MT.Application : Biomass Briquetting Plant is for converting agro forestry waste (Bio-mass) to Briquettes (Bio-coal). Production Capacity of Biomass Briquetting plant ( Jumbo-90) : Output Production Capacity - 1500 Kg/Hr. * Raw material ( Biomass) Specifications : Size of Raw Material - Up to 20mm Moisture contain - Max. 10 %. Output Briquettes (Bio-coal) Specification : Briquettes Diameter / Shape - 90 mm ( Cylindrical Shape) Briquettes Length - Not fixed ( around 1 Feet) Output Production Capacity - 1500 Kg/Hr. Production Capacity :Output capacity is depends on the bulk density of Raw Material. So it will vary with different input raw material. It will be 1200 Kg to 1500 Kg/Hr.Electricity / Power : Total Connected power Load - Approx. 93 HP Practical used Amp. Load - Approx. 80 - 100 Amp Power consumption - Approx. 35 - 40 Unit/MT Individual Electric data : Briquetting Main Ele.Motor - 75 HP Feeding Kupy Ele. Motor - 10HP Screw Conveyor Ele. Motor - 5 HP Lubrication System Ele. Motor - 3 HP Area & Size : Foundation - 16 Feet x 5 Feet Machine Room (For one Machine) - Minimum 25 Feet x 15 Feet Total Area for Project - Minimum 1000 M3 or More Silent Futures of Radhe Engineering Co. - Biomass briquetting Plant (Jumbo-90) : Standard genuine parts with applicable MOC and process Heavy duty Die holder to max binding Output Briquettes Temperature sensors to all bushes to prevent life of bushes. Best design for kupy and worm for feeding up to feeder Box. Standard Reduction Gear & Electric Motors In Auto mode, Whenever Main motor takes more amp load, Feeding Conveyor and Kupy will stop and auto start. Heavy duty body plate and Load wheels. Precesion Engineering & zero load roucing and testing runout at workshop.

Briquette Making Machine

Get Price Quote

Require machine to manufacturing briquettes out of coal powder of capacity 250kghr and briquette 500mg of size

Best Deals from Briquetting Machine

briquetting press machine

Get Price Quote

JUMBO 90 briquetting plant is a high out-put generating machine well-suited for mass production. These machines produce 1200 to 1500 Kg Briquettes per hour. The power consumption of this machine is about 30 – 40 Unit / Hr. This machine produces cylindrical briquettes of 90mm diameter. Jumbo-90 briquetting press machine is a key product offered by Jay Khodiyar Machine Tools. This machine is available at our manufacturing unit that is able to grind and mix up any type of raw material which is available near the area of users. It is made with tremendous quality of parts and gives maximum production of briquettes with less effort. Our all clients can get this high performing Jumbo-90 briquetting press machine from us at their pocket friendly prices. This machine is specially designed by our engineers for huge production of briquettes. As compared to other machine jumbo-90 is only able to pulverize any type of waste in working form with low cost of power. It is counted among the most exceptional and flagship model of Briquetting Press Machine, Briqueting machine from our other products portfolio equipped with cutting technology and manufactured to deliver flawless with maximum output. Some changes are done time to time in the designing and manufacturing process of this model that makes it exceptionally cost effective and technically superior. Provided collection of Jumbo-90 briquetting press machine is specifically engineered for processing and transforming perfect quality briquettes from domestic waste, agriculture waste, forest waste and other types of waste into useful and valuable energy source. Additionally, this model is integrated with highly advanced technology for catering to requirements of high production capacity. Our worldwide clients can get this briquetting press machine from us in both manual and automatic models with wide-ranging configurations.This model is widely acclaimed by our clients because of their salient features such as: Our offered model is manufactured with great feature i.e. maximum production capacity. This model is designed by our experts at our manufactured entity with heavy structure and standard design. Briquetting Press Machine supplied by our company is operated very easily. No loss of production and air pollution due to direct feeding system of this briquetting press. Special sensor system is also installed in this machine to indicate temperature of the machine. We deliver finished jumbo-90 briquetting press machine having high density with 90mm diameter. Lower power consumption and to direct feeding of raw material without hammer mill with minimal maintenance cost

Briquette machine

1,750,000 - 2,500,000 Per Set

5 Set (MOQ)

VAPIWALA & CO mainly engaged in the Research & Development, Manufacturing and Marketing of Nonconventional and Renewable Energy Equipments... Bio-mass Briquetting Plant Bio-mass / Coal Gasifier System Other Energy Equipments The Company was spun-off as an independent organization with carrying the leadership & experience. Key Highlights ISO-9001:2008 Certified Company. CE-Mark Machine Unique blend of passionate professionals. Strong relationships with 400+ active customers worldwide. Enhanced domain focus throug sub verticalization Proactive solutions offerings for improving operational efficiency, complying with industry regulations, and improvident customer service levels. Recognized as a Leader We are gratified that our passion for building stronger businesses and utilizing the agro waste by applying engineering to environment is consistently recognized by independent sources and clients.

Biomass Briquette Machine

0 - 2,700,000 Per

We are the manufacturers of Biomass Briquettes Machnine with different capacity and different out put size like 60mm, 70,, and 90mm size.

65MM MODEL Briquettes Machine

Get Price Quote

The first model developed by us that set off our journey of technological excellence and innovation is Briquettes Machine 65MM MODEL. This model is supported by Hammer mill (Powder Making Unit) to convert raw material into powder form before it is processed to produce Bio-mass Briquettes. This model is best suitable for achieving medium production capacity with minimum capital expenditure.

sawdust briquetting machine

1,309,000 Per Unit

Semi Automatic Briquetting Plant

100,000 Per Piece

1 Piece(s) (MOQ)

Charcoal Briquette Machine

Get Price Quote

A Biomass Briquetting Press machine is also called charcoal briquetting press. The charcoal briquettes made from biomass briquetting. These machines are appreciated for their high tensile strength and long life performance. Coal is one of the most dangerous ways to produce energy nowadays because of its pollution to our environment. The briquettes made from biomass briquettes press and this is carbonized inside so prevent from air pollution. The charcoal briquettes made by biomass briquettes presses have 80% of charcoal. The charcoal from charcoal briquettes plan is easy to transport.

briquetting press machine

Get Price Quote

Our Briquettes Machine 75MM MODEL is the ideal choice of the manufacturers looking for output in the range of 800-1000 kg/hr. and not yet ready for the investment in installation of JUMBO 9075 MODEL. This machine is also supported by Hammer Mill (Powder Making Unit) that breaks raw material in powdery form that is suitable for final process of biomass Briquettes production. Input Bulk Density 140 To 200 Kg/M3. Briquettes have high specific density (1200 Kg/m3) and bulk density (800 Kg/m3) compared to 60 to 180 Kg/m3 of loose biomass.

Wood Waste Briquettes Machine

100,000 Per Piece

Hydraulic Briquetting Machine

Get Price Quote

white coal making machine

2,090,000 Per unit

1 unit (MOQ)

biomass briquetting plant

Get Price Quote

The biomass crusher cum shredder is a first priority product in biomass briquetting process as per it is accustomed for chop the biomass material into smaller particles and suitable size required by individual biomass briquetting plant. Our crusher for biomass briquetting plant offers defined product output, prescribed by the user and used with all types of biomass material

Jute Waste Briquette Machine

Get Price Quote

Briquetting Press

Get Price Quote

All the Briquettes are formed in cylindrical logs using high mechanical pressure without the use of chemical or binder,is also known as Briquetting Machine, Briquetting Press,

Briquetting Machine

Get Price Quote

Crusher Cutter are generally used for threshing crushing raw material having size above 25 mm. If the size of the raw material is above 25 mm then crusher cutter is must, Our Briquette Machine generally accepts raw material up to 25 mm in case of Jumbo-90 & 10-12 mm in case of Super-70 but in the case if it exceeds then the Crusher Cutter is necessary, Generally Straw type waste like Coconut Leaves, Cotton Stalks having size above 100 mm must be crushed in the crusher.

Briquetting Machine

Get Price Quote

Briquetting Press

Get Price Quote

Agro Briquetting Press Machine to our reputed clients. Our machines are contrived using high grade metallic and non-metallic components incorporating complicated technology as per the set industry norms and standards. The agro and wood wastes used for briquetting should be in powder form having moisture content between 10 to 12%only. Moreover our Agro Briquetting Press machine is compatible with wide range of agro-waste material such as husk of palm, rice, soybean, cotton, shells of castor seed, cashew, coconut, groundnut and tea waste, Jute waste, tobacco waste and many more.We are presenting this machine in different models to suit demands of our esteemed clients. Our machines are demanded worldwide by our esteemed clients. The machines are having the features like robust construction, low maintenance, easy installation and prolonged functional life. We are having as highly industrious logistics personnel, who timely deliver Agro Briquetting Press Machine at the premises or our clients to assure their convenience.

biomass briquetting press machine

1,800,000 Per Piece

Briquetting Machine

Get Price Quote

Jay Khodiyar is known for its most promising and technologically enhanced Briquetting Plant JUMBO 9075 among all models as it is designed to deliver maximum output, hold innovations such as Special Sensor System and SpecialSiren System along with making it more Cost Effective and higher demands in market. Briquettes have high specific density (1200 Kgm3) and bulk density (800 Kgm3) compared to 60 to 180 Kgm3 of loose biomass.

Briquetting Machine

Get Price Quote

Briquetting machine, Our extensive range of briquetting machine design processing compact and fully automated equipment like briquetting machine serves as a valuable means to attain energy rich sources and make use of the waste products to the fullest.

white coal making machine

2,500,000 Per Set

Semi Automatic Briquetting Machine

Get Price Quote

biomass briquetting press machine

1,800,000 Per Piece

Biomass Briquette Press

Get Price Quote

Biomass briquetting is the process of converting low bulk density biomass into high density fuel, called briquettes. It is renewable energy eco-friendly concept especially for agricultural counties like african counties. It is a best project to generate revenue from agro-forestry waste and to produce green energy to save the global environment the awareness of using eco friendly & non-conventional bio-coal is increasing day-to-day due with increasing the conventional fuel cost

Powder Briquette Machine

Get Price Quote

The lime powder materials catch businessmen attention in recent years and since 2002 the metallurgy industry has done scientific research so that the quicklime dry powder briquette machine has very wide range of applications in recent days.

white coal machine

Get Price Quote

white coal machine, Briquetting Machine

Briquette Machines

Get Price Quote

1 Set(s) (MOQ)

Our noteworthy entity is actively engaged in manufacturing, supplying, and exporting a wide range of briquette machines in india. Our machine is mechanical piston type continuous production with any type of pure biomass material. We have long experience of installation of briquette press machines in more than 15 countries since last 10 years. We offer foreign installation with training facility with our experienced engineers worldwide.

biomass briquetting plant

Get Price Quote

biomass briquetting plant, Briquetting Machine, Briquetting Press