Ball Valve Investment Castings

145 Per Piece

Stainless Steel 304 Investment Casting

480 Per Kilogram

100 Kilogram (MOQ)

Best Deals from Investment Casting

Investment Casting

Get Price Quote

100 Piece (MOQ)

Micro Tech Impex is the best supplier of investment casting in Gujarat. We carefully control all process parameters like pouring temperatures, shell designs, fluidity, composition, etc. to get high-quality defect-free castings. Our team of qualified metallurgists analyses the microstructures and their phases for consistent quality and repeatability. We house an experienced team of Design Engineers and casting simulation experts to design shells to maximize yield and minimize rejections. We can work with the customers from developing prototypes to manufacturing production parts. We work on the latest design and simulation software for simulating flow, solidification, and cast ability. Order our products in your required quantity today.

Investment Casting

Get Price Quote

100 Piece(s) (MOQ)

We take this opportunity to introduce ourselves as manufacturers of Ferrous & Non-ferrous Investment Castings using Lost wax process. We are an ISO 9001-2008 certified company, engaged in this business since last 5 years & having the best experience in this field. We have a full fledged & well equipped foundry shop, managed by well qualified & experienced personnel, supported by Heat-treatment Shop, conventional Machining facilities, Qc & Test facilities, and much more Which is specialized in the production of various kinds of engineering & commercial parts as under, All types of flanges & dairy equipment parts, Precision parts as per drawings sample & Much More,

Duplex Steel Investment Castings

650 - 850 Per Kilogram

500 Kilogram (MOQ)

Investment Casting Components

Get Price Quote

Precision-engineered components for the oil and gas industry by Vasuki Technocast. Our high-quality manufacturing ensures durability and reliability in every part. Your trusted partner for energy sector needs.

Investment Casting Parts

Get Price Quote

We make available investment Casting Parts which are reckoned for their make and long service life. Capturing the market with our exceptional product range, we are located in Gujarat(India) and cater to the wide market. In order to attain complete client credibility, we let the clients' to choose either online mode or offline mode for making payment. And, we guarantee for authenticity and confidentiality.

Process Equipment Casting

Get Price Quote

100 Kilogram (MOQ)

Part is made as per customer Requirement ,drawing and specification. process- lost wax Investment casting. Our capability Production Capacity: 500 Metric Tones Annum Job Handling Capacity: From 10 grams to 100 Kg. Single Piece Materials Grade of Casting CF3, CF3M, CF8, CF8M, WCB, LCB, WCC, LCC, HCHCR, CA-15, CA-40, SS-321, CZ100, EN8, EN9, EN19, EN24, EN31, EN36, EN41, DIN17445, 20MNCr5, 25CrMo4, 282CrMo, Din 4136, SAE8620, CN7M, CD4MCu, NICKEL BASE, Ni-HARD, LM5, LM6, LM20, COBALT BASE Material Hast Alloy etc. Also As per customer requirement and specification. Quality Certification Quality management Certification ISO 9001:2008 From TUV Rheinland. And PED 201468EU TUV Rheinland Certified for Pressure related component.

Investment Castings

Get Price Quote

Investment Casting

1 - 1,000 Per Kilogram

10 Kilogram (MOQ)

Stainless Steel Investment Casting

Get Price Quote

foundry investment casting

65 Per Kilogram

Minimum Order Quantity: 1000 Kilogram.................................................................

Automobile Castings

Get Price Quote

Investment Castings

Get Price Quote

Investment Casting

Get Price Quote

1000 Piece (MOQ)

Precision Investment Castings

Get Price Quote

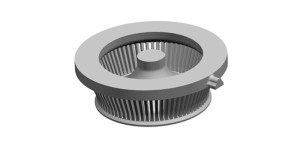

Precision Investment Castings that we offer are produced using lost wax process. It allows the production of parts in high or small volume with extraordinary precision in most cast able metals. We are counted among the top companies, which are engaged in manufacturing, supplying and exporting Precision Investment Castings. The manufacturing and testing of our Precision Investment Castings are done under the supervision of experts Inhouse. Characteristics High production rates, particularly for small components. High dimensional accuracy and consistency. High integrity castings. Extremely good surface finish obtained. Complex shapes can be cast. Long or short runs can be accommodated. Machining can be eliminated in most cases. Minimum shot blast and grinding needed. Almost any alloy can be cast. Lost Wax Process Special Wax is injected into metal die to make wax patterns. Wax patterns (replica of part) assembled into a cluster around a wax runner system. The “Tree” of patterns then coated with layers of a refractory material. Each layer being dried or chemically cured before the next layer is applied. Assembly is heated to remove the wax & fired at high temperature to bond the mold. The mould is heated and molten metal poured. When cool, the mould material is removed. Castings are removed from the runner system for secondary process and final finishing. Our capability Production Capacity : 1600 Metric Tons / Annum Job Handling Capacity : From few grams to 195 Kg. Single Piece

super alloy casting

Get Price Quote

Our team makes every effort to present a qualitative and certified array of products. Our organization is renowned among reputed suppliers of premium and superior grade superalloy casting across the nation. Our Alloy Castings have a protective polish on the surface with a lightweight body and a long service life.

Investment Casting Components

Get Price Quote

Available in diverse sizes, the Investment Casting Components, which we offer, are manufactured using premium casting parts. Our Investment Casting Components include die casting finished components such as pump impellers, gear housing, casting body, etc. We are the dependable Manufacturer, Supplier and Exporter of Investment Casting Components. Highlights Superior finishPremium raw materialsDimensional accuracyLong life

Investment Casting

Get Price Quote

We can supply investment casting parts for valve ,pump, fire fighting, ancinator parts, automobiles and general engineering industry.

Investment Casting

Get Price Quote

We are main supplier of this product.