Clinker Grinder

Get Price Quote

Based in Rajkot, Gujarat, India, we are actively functioning as the prominent Manufacturer and Supplier of Clinker Grinder. Our Clinker Grinder Spares are made from high-grade basic materials like iron, etc. and thus ensure durable finish. We offer different kinds of clinker grinder spares and others spares including Split Lantern Ring, Wear ring, Gland Follower and Bearing Housing Back Cover. Our team of dexterous professionals checks these Clicker Grinders on various strict parameters to ensure the best quality reach the buyers. For reasonable prices, contact us.

cement pipe machine

150,000 - 160,000 Per Nos

1 Piece(s) (MOQ)

Best Deals from Cement Plant Parts

cement mixer machine

Get Price Quote

Cement Plant

Get Price Quote

Cement Plant Cement Grinding Unit For Sale with Land. Built Up Area 4 Acres Approx. Presently on Production. Total Capacity 300 MT.

Rotary Kiln

Get Price Quote

As a famed organization in Rajkot(India), we make sure that our customers will receive their orders at their preferred destination. We are reckoned amidst the well-known Suppliers of Rotary Kiln as we offer only the best quality products.

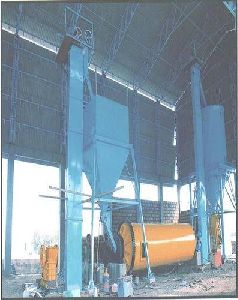

Bucket Elevator Cement Plant

Get Price Quote

1 set Kilogram (MOQ)

we offer Bucket Elevator Cement Plant. In order to fulfill the changing demands of our clients, we have been engaged in offering Bucket Elevator. Developed by our professionals using advanced engineering concepts, these find their applications as vertical lifting of material such as rice, coffee, food grains and other granular material. Some of the features of our range is mentioned below: Sturdy construction Excellent performance Durable finish standards Low maintenance cost

Cement Kiln

Get Price Quote

Used for diverse commercial and industrial applications, our Cement Kiln is offered with turnkey sponge iron plants. We are the foremost Manufacturer and Supplier of Cement Kiln in India, thus take great care while designing it. Our Cement Kiln can be acquired at the market leading prices. Used For Hardening, burning or drying materialsSmelting ore for extracting metal

Adhesive Coating Plant

Get Price Quote

We are offering adhesive coating plant. Adhesive coating lamination machine works in terms of electrical heat source. The gravure equipped with adhesive coating lamination plant supports for coating adhesives on labeling and packaging film materials. This is a suitable option to produce variety of packaging films with adhesives applied on it.

Cement Concrete Pipe Machine

Get Price Quote

Plaster Of Paris Powder

Get Price Quote

Known for its lasting whiteness, the Plaster of Paris Powder that we offer is of high quality. The purity of the Plaster of Paris Powder that we offer is indicated by its clean whiteness. Our Plaster of Paris Powder is free from impurities and other foreign particles. We manufacture Plaster of Paris Powder using quality base materials. The Plaster of Paris Powder is available to clients at reasonable prices. Used In Fireproofing applicationsBuildingsArts and craftsMedical sectorArchitectural designs

cement pipe machine

Get Price Quote

The plant has modern facility for manufacturing quality products..It has technically strong management team having rich and diverse experience in Bearing Indusrty & Cement Pipe machine.

cement pipe machine

Get Price Quote

The Reinforced cage is first prepared on the collapsible reinforcing machine by hand process. The cage is then placed inside the pipe mould, which is then hoisted up and mounted horizontally on the Runner machine. It is rotated by 'speed veriater Machine. The rotation is kept slow in the beginning and then the speed is increased. The concrete mixture is prepared material by mixing cement stone, metal and send respectively. The cement concrete is fed into the moulds during rotation, which spreads inside evenly. The time required for completion of this operation depends upon the diameter and class of the pipe. The pipes are kept mould for 24 hours. On the following day the pipes are removed from the moulds and submersed in water in the curing tank for about 15-20 days depending upon the class of the pipe the specimen of the pipes are subject to the following tests viz : 1- Hydrostatic pressure test , 2- Three edge bearing test, 3 - Absorption test.

Cement fly Ash Feeding System

Get Price Quote

We are offering cement conveying system (cementfly ash feeding system) goes hand in hand in the timely completion of construction linked projects which plays a pivotal role in infrastructure growth. Acme air equipments co. Pvt. Ltd., an iso 9001-2008 quality certified company, manufactures cement conveying system (cementfly ash feeding system) of highest quality standards in the state-of-art manufacturing setup along with comprehensive industrial solutions. This covers systems with feeding ratecapacities of up to 50 tones per hour.

Cement Silo Machine

Get Price Quote

We are leading manufacture and supplier of Cement silo or Fly Ass Silo from 40 Tones to 150 Tones that are in line with the highest quality standards prescribed by the industry. We are offering Storage Silos to our clients which are mainly a part of the concrete industry use at RMC Plant. Which are fabricates from superior quality of Mild Steel. This cement or fly ass silo is highly durable and at competitively priced. We can also manufacture that silo as per the specific requirements of our clients. General Technical specification of the Silo Shell is as below : Diameter of Silo: 2500/2800/3400/4000 mm. Thickness of plate: Shell 5 mm and bottom cone 6 MM and Top cone 5mm. 4 / 6 legs each is 200 NB or ISMB 200. Railing, Cage Ladder, Manhole on Top of Silo Included in Scope of Supply. Cement Feeding Pipe Dia. 4” up to Foundation to Top Level.

Cement Tiles Machine

Get Price Quote

Construction : Main Body Fabricated from Steel Control Shaft is moving on Ball Bearings and thrust Bearings provided on the same Motion to the disc is given through Helical Bevel Gears of Alloy Steel Resurfacing Arrangement : Attachment is Provided in the Machine to resurface the disc which operates automatically through Super Gear Train Capacity : In Terms of Nos. of Tiles Size : 25 cm x 25 cm at a time For Grinding 28 Tiles at a time Plate / Disc Size : 200 cm x 200 cm Power Consumption : 5 H.P. 1440 RPM Machine Speed : 100 to 110 RPM Machine Size : 200 cm x 142 cm x 142 cm

Cement Plant

Get Price Quote

We are manufacturers and exporters of cement plants like mini cement plant, clinker grinding unit, cement bagging plant and many others. We take in charge the execution of complete Mini-cement plants and their units. Our Mini-cement plant machine design made by our experienced team.

Adhesive Lamination Plant

Get Price Quote

cement brick making machine

Get Price Quote

We are the main supplier of this product.

cement kilns

Get Price Quote

Mini Cement Plant

Get Price Quote

Dry Mix Plant

Get Price Quote

Our company is enthusiastically engaged in offering our clients a broad range of Dry Mix Plant that is obtainable in numerous technical specifications. Offered dry mix plant is assembled with utmost care by our highly skillful professionals by making use of high quality components. Provided dry mix plant is extremely appreciated amongst our customers due to its outstanding features like high efficiency, hassle free functionality and precision designed. Features: Tough design High performance Anti corrosive body

Flyash Cement Block Machine, Hydraulic Cylinder

Get Price Quote

We are offering flyash cement block machine, hydraulic cylinder etc. fly-ash cement block machines are widely used in the production of cement blocks. Such machinery requires perfect hydraulic system for exact pressure, zero-zero movement of all the cylinders along with precise and smooth movement of flyash cement block machine hydraulic cylinder. Matching up with all these requirements, our flyash cement block machine hydraulic cylinder that we offer is high on demand. The flyash cement block machine hydraulic cylinder, we provide, consists of all these qualities which a cement block machine requires. We can customize these flyash cement block machine hydraulic cylinders as per the requirements of the clients and the necessity of machine. we also offer : power pack unit and its control panel to assemble with the cylinders used in the machinery

Cement Feeding System

Get Price Quote

Cement Feeding System, Auto Coater, vacuum transfer system, Sizing Machine

cement concrete mixture machine

Get Price Quote

cement concrete mixture machine, Garage Tools, Hydraulic Press

cement machines

Get Price Quote

cement machines, cement mill machine, grinding mills machine, HYDRATE LIME

mini cement plant machinery

Get Price Quote

mini cement plant machinery, Elevators, Gear Box, heavy gear machinery parts

Cement Block Machine

Get Price Quote

Cement Block Machine, cement mixer machine, Construction Machinery

cement making machine

Get Price Quote

We are offering Cement Making Machine such as Rotary Kiln,Coal Mill,Cement Mill,Raw Material Mill,Dry Mortar Production Line etc.

cement bag making machine

Get Price Quote

cement bag making machine, Aluminium Bottle Making Machine, recycling machine

Vertical Shaft Kiln

Get Price Quote

Vertical Shaft Kiln, Bagging Machine, sponge iron feeding system