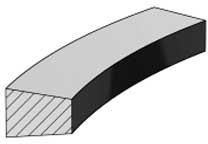

Full Keystone Compression Ring

Get Price Quote

A compression ring with a wedge cross section. With its tapered sides, radial movement of the ring in engine operation will cause the axial clearance in the groove to increase and decrease. This greatly reduces ring sticking, as the ring continuously works its way free of the combustion residues. These rings are designed with an overall side angle of 6° bzw. 15o, the larger angle being more effective against the tendency to coking. The keystone ring is used in the top groove in passenger car and truck diesel engines where ring sticking must be expected.

Compression Piston Rings

Get Price Quote

The company is one of the well-known Manufacturers and Exporters of Compression Piston Rings in Ahmedabad (India). The top Compression Rings is present in the first ring grooves. The Compression Piston Rings, offered by the company, has the primary function of sealing the combustion gases. The Compression Piston Rings are also the primary means for the transfer of the heat from the piston to the piston walls. Various types of Compression Piston Rings are designed in accordance to the specific applications they are used in. Common Types Of Compression Piston Rings Rectangular Ring : A Piston Ring with rectangular cross section. The Rectangular Ring is a simple shaped Piston Ring that performs the sealing in the normal operating conditions. The Rectangular Rings are used in marine and diesel engines, garden equipment, power plants, internal combustion engines, and rotary seals like industrial valves, shock absorber seals and blowers.Taper Faced Ring : A Piston Ring with tapered face. The Taper Faced Ring contacts the cylinder bore with the outer edge at the bottom. This particular feature of the Taper Faced Ring is useful in shortening the running-in time and improving the oil scraping. Taper Faced Rings are the primary installations in the second groove in various applications like Compressors, Marine Engines and Locomotives to name a few.Internally Bevelled or Stepped Ring : Provides edge relief to the top side of the Rectangular Ring and Taper Faced Ring. The design of the Internally Bevelled or Stepped Ring is such that it offers a twist effect which brings it into bore contact with the bottom outer edge only and that too, without gas pressure loading. The inner edge of the Internally Bevelled or Stepped Ring contacts the bottom groove side. The Internally Bevelled or Stepped Ring helps in improving the oil consumption control and is used in various industrial applications like Compressors, Hydraulic applications and Garden Equipments.Keystone Ring : Comes with both sides tapered and is used in if any kind of ring sticking is possible due to the wedge shape which may lead to some sort of radial movement. This can possibly alter the axial clearance and thus limit the combustion residue build up. These Keystone Rings are mainly used in the automobile engines where the chances of the occurrence of sticking are there.Half Keystone Ring : Have one tapered face which is usually facing the combustion chamber. The Half Keystone Ring also reduces the ring sticking. These types of Piston Rings find common usage in the various two stroke engines like snowmobiles. The Half Keystone Rings are also used in garden equipments and earth moving equipment.

Best Deals from Compression Rings