Control Cable Arm

Get Price Quote

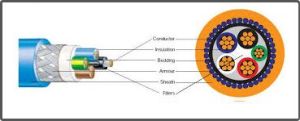

Applications - Used in fixed wiring, underground wiring, industrial control wiring Conductor - Solid /Fine strands of electrolytic grade annealed copper conductor tinned/bare Insulation - Insulated with special grade PVC/HR PVC/FR/XLPE Armoring - Galvanized steel wire or strips or double helical steel tape armoring for single core cable. Sheathing - Special grade PVC/general purpose PVC/FRLS PVC outer sheath Color - Black colors Size - 1.5 Sqmm to 2.5 Sqmm upto 61 Cores Voltage - Working voltage grade 1100 Volts Test voltage 3000 Volts Temperature Range - Normal working temperature -20°C to 70°C. High working temperature -20°C to 90°C Packing - In 500/1000 Mtr. length Higher sizes on drum

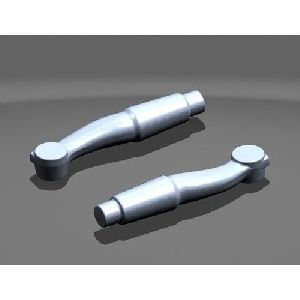

Forging Control Arms

Get Price Quote

Best Deals from Control Arm

lower control arm

Get Price Quote

Lower Control Arm, aluminum forged control arm, car lower arm Lower Control ArmThe lower control arm was a key part of front suspension which controls the wheel trace and transmits load exerting on the wheel by the road to other parts of the car. When the car was running on the road, the lower control arm was subjected to complex loads alternating with time. Thus, the mechanical performances, usually relating to strength and stiffness were critical to the safety and reliability of the car. Recently, many analysis and optimization methods and tools for structure design based on control arm have been introduced into automobile industry.DN Forge Industries is a leading manufacturer and Exporter of World class Machined Components, Assemblies and forgings from ferrous and nonferrous material for auto and non automotive industries. Starting with a medium-sized Forge Shop and machine shop, we have in the span of three decades established ourselves as a reputed player in the industry. Today, we can proudly claim to be component manufacturers, catering to the OEMs of repute in the Indian and Overseas markets. Our growth in the industry is a result of our obsession with meeting customer needs on a sustained basis. Today, our services cater to the forging needs of major industry players across diverse industries with quality products at competitive prices. Our reach is the vindication of the commitment and reliability we provide to our customers. DN Forge industry is a team of 65 production associates and staff who manage marketing, design, production, and quality control. We are a diverse family of engineers, technical experts, technicians, and sales and support staff, each of whom has a wealth of experience. Despite the difference in backgrounds and experience, the team has one thing in common: total commitment to customer satisfaction. In order to ensure focus and quality, each Company within the Group has specialized in the manufacture of a particular set of items. Vision Uphold the Recognition and Reputation as value based source for World class Machined Components, Assemblies and forgings Components both National and Internationally. Mission DN Forge Industries mission is to establish a company that can provide unique specialized services to various vital business sectors, with the tools of innovative strategies and in hand talent. The key to our success can be summarized briefly in our untiring efforts to create a magnum opus in each of our job. Our company’s sights are on the future, but we are diligently aware of their customers’ needs in the present. Quality Policy Our TEAM shall delight the customer by delivering Error Free Products through continuous improvements at all levels and conformance to customers requirement through effective implementation of QMS. We also shall strive to achieve Clean and Green Environment. Director's Message With our strong market position, business mix and clear strategic focus DN Forge Industries has earned the confidence of valued customers and is ideally positioned to further strengthen The TRUST by continuously evolving and addressing the implied expectations of the customers in addition to explicit ones. CORE STRENGTH Atomized production technologies. Precision Machining, Casting, and Forging. Capability to work with multiple raw materials. In House Design and R and D Facility. New Product Development and Program Management Dedicated program management processes and functions. Over 30 years experience in new product development. In House die designing and development capability. Value Engineering process. Experienced Manpower