edible oil refinery plants

5,400,000 - 6,000,000 Per PLANT

1 Piece (MOQ)

We are the leading supplier of Edible Oil Refinery Plant made from high quality material at competitive prices.

Edible Oil Refinery Plant

Get Price Quote

Best Deals from Edible Oil Plant

Edible Oil Refinery Plant

Get Price Quote

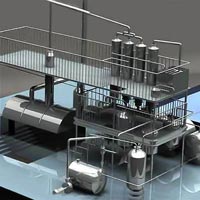

Edible Oil Refinery Plant: Edible Oil Refinery: Edible Oil RefiningTinytech Udyog has been in the edible oil industry since 20 years. We are designers, manufacturers and global exporters of Edible Oil Refinery Plants for the refining of almost all kinds of crude oils. We have carried out successful worldwide turnkey installations of edible oil refinery plants and oil mill projects. Kindly note that the below photograph has been copied by many other companies who have put up on their website. But in actual the below photograph is of TINYTECH EDIBLE OIL REFINERY PLANT which is erected at our Tinytech Showroom Office. Main Equipments of Edible Oil Refinery Plant include the following: Neturalizers Oil Filter Presses Bleacher Oil Storing Tanks Deodourizer Soap Pans Cooler Vacuum Equipments Thermic Fluid Boiler Valves, Motors, Pipelines Vacuum Pump and the Steam Generators for the Edible Oil Refinery Plant cannot be seen in the above picture as they are on the back side. Moreover, the Catchalls with 40 Ft. tower and the Barometric Condenser are also not shown here. The Process Description for Edible Oil Refining is stated as under: For refining any crude edible / non-edible oils, there are mainly three basic processes which are carried out in the refinery plant. Neutralization Process First process is neutralization in which the oil is neutralized in order to remove the Free Fatty Acids (FFA) by adding caustic soda. Oil is heated up to about 60°C by thermic fluid coils and oil is stirred by the stirrer. Soap stock formed due to chemical reaction is allowed to settle at the bottom of the neutralizer from where it is taken out into respective soap pans. Bleaching Process The neutralized oil is then transferred for the bleaching process where the color of the oil is removed. The bleaching process is carried out with the help of respective chemicals such as carbon black, bleaching earth etc. Oil is heated up to high temperature of around 100°C under vacuum with continuous stirring operation. Deodorization Process The bleached oil then goes to the filter press where the spent chemicals are separated and clean bleached oil is obtained. This oil goes to deodorizer where the oil is to be heated above 110°C and under vacuum by providing live steam from the bottom. The temperature of the oil is raised up to certain limits. The entire process of deodorization is very crucial for the quality of the oil. Finally, the smell and unpleasant odor from the oil is removed. Cooling Process The high temperature oil is to be cooled in the cooler where the water circulating coils take away the heat. The cooled oil is again allowed to pass through the filter press for the final filtration process. Finally, totally clean, filtered, refined transparent oil is obtained at the output.During entire refining operation, all the equipments such as thermic fluid boiler, vacuum pump, vacuum equipments, barometric condenser, catchalls, steam generators, oil filters, electric motors, oil pumps etc. play their respective role. So all these equipments are very important parts of the refinery and they are connected with the vessels through pipelines. Dewaxing Process Some oils such as corn oil / maize germ oil and sunflower oil contain considerable amounts of waxes in them. Sometimes these waxes give very hazy appearance to the oil and it is advisable to remove these waxes. In such cases separate dewaxing process is carried out. Our Tinytech refinery plants are equipped with dewaxing units in order to remove the waxes from the oil and making it more stable and palatable. Fractionation Process For refining the palm oil, the above method is carried out with slight process modifications. There is addition of few extra equipments in the refinery such as chilling plant, crystallizer etc and the fractionation method is performed. Tinytech Udyog possesses expertise in the palm oil refining and our palm oil refinery plant is most advanced giving ultimate palm oil refining results.

Edible Oil Refinery Plant

Get Price Quote

there are three basic processes in the edible oil refinery. First process is neutralizing the oil in the neutralizer to remove the Free Fatty Acids (FFA) by adding caustic soda. Oil is heated upto about 60°C by thermic fluid coils and oil is stirred by stirrer. Then soap stock formed due to chemical reaction is allowed to settle at the bottom of the neutralizer from where it is taken out into soap pan

Edible Oil Refinery Plant

Get Price Quote

Edible Oil Refinery Plant completes the entire procedure in three basic processes. First process is neutralizing the oil in the neutralizer to remove the Free Fatty Acids (FFA) by adding caustic soda. After the completion of this process, soap stock formed due to chemical reaction is allowed to settle at the bottom of the neutralizer from where it is taken out into soap pan. Then, neutralized oil is drawn into the second vessel called bleacher where color of oil is removed by bleaching process with aid of chemicals such as carbon black and bleaching earth. Bleached oil then goes to the filter press where bleaching earth and chemicals are separated and clean bleached oil is then drawn to deodorizer where oil is heated above 110°C through thermic fluid coils. The entire process is done under high vacuum. Edible Oil Refinery Plant comprises of Thermic Fluid Boiler, Vacuum Pump, Barometric Condenser, Catch0ls and Steam Generator.

Edible Oil Refinery Plant

Get Price Quote

Edible Oil Refinery Plant, activated bleaching earth, soap adsorbent powder

Edible Oil Refinery Plant

Get Price Quote

Edible Oil Refinery Plant, Oil Mill Machinery, animal feed machinery

edible oil plant

Get Price Quote

edible oil plant, Edible Oil, Seeds, Paper Products