Unicoat Gw Graphite Coatings

42 - 48 Per Kilogram

30 Kg (MOQ)

Graphite water base coating

Silicone Coating

Get Price Quote

Only high quality raw materials have been used for the production of our entire range. We check the raw materials against varied quality parameters before procurement. Backed by a hardworking team, we are capable of offering the Aluminum window Corner as per the exact requirements of the buyers.

Best Deals from Epoxy Coatings

Stainless Steel Coating

Get Price Quote

Are you on the lookout for a trusted company that provides Stainless Steel Coating service in Ahmedabad? If your answer is an emphatic yes, choosing us will be an optimum choice for you. We have been working in this domain and have expertise in providing Stainless Steel Coating service for different types of surfaces. The Stainless Steel Coating service, offered by us, is rendered by seasoned professionals using the latest tools and techniques in accordance with the international quality standards.

Rapid Coating Powder

270 Per Kilogram

1000 Kilogram (MOQ)

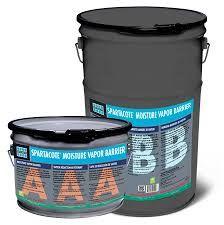

Moisture Barrier Coating

200 Per Litre

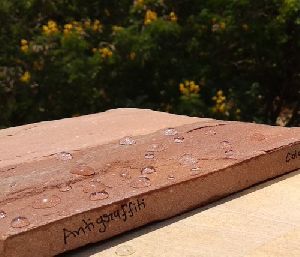

Anti Graffiti Coating

Get Price Quote

1 Litre (MOQ)

Weber SBR Waterproof Wall Coatings

Get Price Quote

Weber SBR Waterproof Wall Coating serves as an excellent polymer modifier for concrete or cement mortar. It is basically styrene butadiene co polymer latex liquid which can be used for the waterproofing and repairs of spalled concrete. It can be used for several purposes as a binding agent, waterproofing agent, polymer modifier and for structural repairs. It offers an excellent bond making the structure impermeable to liquids. Besides, it is chemical, abrasion, impact and slip resistance. Benifits It provides an excellent bond to the existing substrate. It makes the structure impermeable to liquids. It improves chemical, abrasion and impact resistance. It has improved flexural strength and hence avoids cracking. Shrinkage cracks are reduced. Thinner screeds can be cast for similar strengths,reducing weight and material used. It has excellent slip resistance when used for flooring screeds. Recommandation Bonding agent-Old to new concrete bonding, bonding for plasters. Structural repairs – For spalled concrete, beams, precast segments etc. Waterproofing ( Internal) - Lift pits, basements, toilets etc. Polymer modifier for floor screeds - Can be used as an underlay for epoxy floorings. Direction to Use Surface Preperation Clean the substrate of oil stains and bond inhibiting compounds. Also remove dirt, dust and laitance, if any, using high pressure water jet or any other suitable method. Corroded reinforcement bars should be exposed around their full circumference, should then be cleaned to remove all the loose particles and should be treated with an anti-corrosive product. Application as a slurry bond coat Surface must be thoroughly dampened before the application and excess water should be removed. weber sbr is a ready to use liquid which is dispensed into the water as per the proportions given in the *recommendation chart to form slurry. Apply one coat of the slurry using a stiff brush, working it well into the surface. Place the new concrete while the bond coat is a little tacky. As a concrete repair and bedding mortar Expose the spalled concrete upto the reinforcement bars. Corroded reinforcement bars should be exposed around their full circumference and then be cleaned to remove all the loose particles.They should then be treated with anti corrosive product. Apply weber sbr as a bonding agent between the existing and new repair mortar as recommended above. Mix weber sbr and water thoroughly in one bucket, and mix sand and cement as per the *recommendation chart given in another bucket.Then add the liquid mix to the mortar mix and ensure thorough mixing to form slurry. As the bond coat is slightly tacky, apply the slurry mix and build up the entire cross section to be repaired. Note : weber sbr can be used only for repairs in internal applications only. As a waterproof slurry coat Surface must be thoroughly dampened before the application and excess water should be removed. Mix weber sbr and water thoroughly and add cement into this mix as per the proportions given in the *recommendation chart. Apply the first coat of slurry using a brush and apply the second coat in the direction perpendicular to the previous coat. Apply the second coat while the first coat is slightly tacky,approximately after 2 hours. As a modifier for plasters Mix weber sbr and water in one bucket, and mix cement and sand in another bucket as per the *recommendation chart. Mix the liquid to the mortar in order to obtain a polymer modified plaster. This modified plaster can be used for internal as well as external applications. It can also be used for bonding the plaster to the existing substrate for internal surfaces.

Fasteners Surface Coating

Get Price Quote

Zinc PhospatizingPTFETEFLON®XYLAN®XYLAR®Mechanical Zinc PlatingZinc Flake CoatingWax CoatingMolyKote®Electro-less NickelHot Dip GalvanizingRilsan ® Fine Power CoatingMaximum Job Size: 1850 x 1850 x 1250 MMProduction Capability: 2-4 MT per day.

Silencer Coating Spray

Get Price Quote

Zircon Coatings

Get Price Quote

These are solvent or water based, fusion inhibiting, refractory coatings to be applied on mould walls or cores primarily to give good surface finish and consistent casting quality. This is achieved by Enabling better molten metal flow characteristics thus enabling better filling in intricate mould cavities Preventing surface defects such as metal penetration, sand burn-on (fusion), carbon pick up, sand expansion defects (such as veining, rat tail, finning etc.) or lustrous carbon defect. Preventing mould wall erosion and thus subsequent inclusions in molten metal Improving stripping characteristics of castings

Waterproof Coating

Get Price Quote

A premium quality 100% Acrylic elastomeric coating specially formulated for waterproofing to form a seamless membrane, which is resistant to sunlight, heat, water and most chemicals, typically used as waterproofing and as a topcoat for roof coating to protect the UV rays for reducing heat at bottom. It provides superior protection to built-up and gravel roof systems, may also be used on galvanize steel, concrete and urethane foam roofing, it gives outstanding durability because of its UV protec Features Forms a flexible coating that protects against UV rays, Heat and pounded Water May also used on metal, wood, Concrete and Masonry Surfaces May also used on Galvanized Steel Surface Preparation Surface must be clean, dry and free from dust, grease, mildew and wax remove any loose and peeling parts and prime with America’s colour primer. If surface is glossy should be sanded to a dull finish If mildew is present the surface should be washed with chlorine bleach solution (20% household bleach and 1% liquid detergent in warm water) If Concrete is new then allow for 30 days prior to application The PH of Concrete should be less than 10, check by PH paper, if Surface is not within the 10 PH and large amount of efflorescence. (efflorescence is seen as a white salty deposit on the concrete surface) are present then the concrete should be acid etched prior to painting ( etching solution is 1 part of commercial HCL and 3 parts of water mix) and apply uniformly the wash with clean water and allow to fry the surface. The Concrete must be dry prior to coating (less than 12% moisture content) but f the surface is totally dry then spray little water on the concrete prior to painting will help the paint to penetrate into the concrete. Latex base sealer or Primer must be applied first to reduce the exposure to alkali conditions

Protective Coatings

Get Price Quote

Protective Coatings, energy savings, high temperature leak-resistance, insulation, fire protection and low friction. Ultra-Therm ULTRASLIDE - HT Ultraslide - S Ultracoat FP Ultra -ZCOAT Duraback Ultra Protect - SPL XTRA GRIP

Epoxy Based Top Coat

Get Price Quote

Silicone Coating

Get Price Quote

Silicone Coating

Hybrid Epoxy Polyester Powder Coatings

Get Price Quote

Hybrid Epoxy Polyester Powder Coatings, Powder Coating Powder, Dyestuffs

Epoxy Polyester Powder Coating

Get Price Quote

Epoxy Polyester Powder Coating, Powder Coating Powder, Powder Coating

High Temperature Refractory Coatings

Get Price Quote

High Temperature Refractory Coatings, Binders Foundry Coating

Plasma Coating

Get Price Quote

Plasma Coating, Coating, Monel Sand Casting, Springs

Seed Coating

Get Price Quote

Seed Coating, Bio Fertilizers, Bio Fertilizers Granules

Surface Coatings

Get Price Quote

We are offering surface coatings hand anodizaing aluminum component coatings are a special process and a demanding science. The company established facilities to hard anodize fully machined forged aluminum components. Hardness in the range of 400 – 450 hv can be achieved on the surface, making the product virtually wear proof and anti file. The plating thickness ranges from 0.015mm to 0.060mm. The company also specializes in providing different colours in anodize plating. Apart from hard anodizing the company also performs the following plating. tin plating. (immersion process) graphite coating. (spray process) graphite screening. (screen printing process)