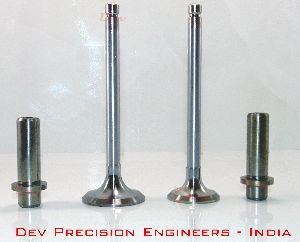

Engine exhaust valve

200 - 2,000 Per Piece

5 Set (MOQ)

We offer an all encompassing range of valves, which contains intake valves, exhaust valves and engine valves. Our engine valves are manufactured using superior quality chrome plating / valve steel series- EN18D, EN24, EN52, EN54, EN59(214N) (Non-Magnetic/Bimetal) with varied hardness from 20HRC to 50HRC. Available in over sizes, these engine valves are extensively used in automobiles, tractors, industrial & diesel engines, generators and two wheelers.Our intake and exhaust valves are manufactured from a variety of materials to be operated under different conditions. These valves are manufactured using super Material Carbon steel, martens tic steel with chrome and silicon, stainless martensitic, stainless austenitic, Inconel and Nimonic. These valves are available in different dimensions & material as per the usage and the application of the valve.Normally, our intake valves are manufactured from high quality alloy steel, as these valves are not exposed to the corrosive action of the hot exhaust gases. Consequentially, these intake valves provide the users long time hassle free service. For manufacturing exhaust valves, we use chromium silicon, which makes them resist to corrosion due to high temperature and hot gases.Various type of heat treatments its definition and objectiveIt is defined as an operation or combination of different operations involving heating and cooling of metal or an alloy in solid state for the purpose of obtaining certain required structures and desirable properties of a combination of properties suitable for the particular application.Heat treatment is carried out to achieve one or more of the following objects: To relieve the stresses set up in the material after hot or cold working in order to improve machine ability. To improve mechanical properties like tensile strength, hardness, ductility, shock resistance etc. To modify the structure of the material to improve its electrical and magnetic properties. To increase the qualities of a metal to provide better resistance to heat, corrosion and wear. Following heat treatment processes are mainly in use for achieving most of the objects of heat treatment: Annealing Spheroidising Normalising Hardening Tempering Case hardening or surface hardening Carburising Nitriding Cyaniding Induction hardening Flame hardening

inlet exhaust valves

Get Price Quote

We are known as the prime Inlet Exhaust Valves Manufacturer, Exporter and Supplier in India and Abroad. We procure the quality raw materials from the prominent Japanese and European vendors. Our Inlet Exhaust Valves are made up of chrome-silicon alloy steel and chrome-nickel-silicon alloy steel that impart resistance against high stress and high temperature. To increase the life of the Inlet Exhaust Valves, it is passed through Liquid Nit Riding process or Hard Chrome Plated.

Best Deals from Engine Valves

Inlet and Exhaust Valve

Get Price Quote

100 Set (MOQ)

Inlet/ Exhaust Valve Shri Ram Engineers are able to supply Valve Spindles of various engine models regardless of 2 stroke or4 stroke. We believe quality of the component plays a vital role increasing the performance of engine & extending the time between two overhauls. Our manufactured valves are offered with various materiel according to the specification from the customer. Grades Offered: EN 52, 21-4N, Bimetallic & Nimonic. We are able to offer with Sizes: Head — 50MM to 130MM, Stem - 14 MM to 30MM, Length — 100MM to 7OOMM

Inlet & Exhaust Valves

Get Price Quote

We are engaged in trading of technically advanced Inlet and Exhaust Valves that are offered in a wide range of material composition such as EN24(BS817M40), 21-4N(BS349S52), EN52(BS401s45), etc. Our Valves are developed by gathering upset forging process. The Bimetallic Valves are friction welded. In addition, we also offer various processes such as Stellite on Seat, Chrome Flash on Stem, and Nitiding/Tuftriding Tip Area. Special Features Durable Long lasting in nature Adhering to the international standards Made By Metal gathering upset forging process Friction welded

Tappet for Marine and diesel engine

300 - 1,500 Per Set

200 Set(s) (MOQ)

Manufactured with latest machines and technology. Material as per requirement. Finish as per requirement. Logo as per requirement.

automotive engine valves

Get Price Quote

100 Piece (MOQ)

"Black panther" brand Spare parts manufactured & exported since 1960. In house production of most spare parts with under stringent quality control. Products exported to more than 70 countries worldwide. More than 10,000 products on list for more than 500 types of German, British, Russian, American, Polish, Italian, French, Japanese, Indian & many more engines, all our products are OEM quality in terms of material, process & finishing. 100% export company. 62 years of experience in specializing engine parts. 99% repeat order track speak about our commitment on quality & Customer Service.

Rado Star Engine valve

Get Price Quote

The Engine Valves, which we deliver, ensures that the engine works proficiently under demanding situations. In order to make hassle free transactions, we have adopted an online payment procedure that ensures immediate transfer of money and confidentiality of clients' information. With the assistance of sophisticated packaging system and adroit professionals, we are able to provide flawless lot of products as we ensure complete safety during packaging.

Marine Engine Valves

Get Price Quote

The Marine Engine Valves, which we make available, are used for diverse marine engines such as Deutz Engines, Perkins Engines, Cummins, etc. Different types of Intake and Exhaust Valves are used in different engines. Our Marine Engine Valves are manufactured using the best grade materials. We are one of the most trusted Manufacturers, Suppliers and Exporters of Marine Engine Valves. Why Our Marine Engine Valves? Best Grade Raw Materials Used : EN8, EN32DurableEasy to fitExcellent finish

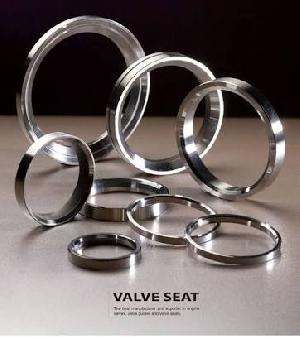

Valve Seat Inserts

Get Price Quote

We are manufacturer of Engine valves for all kind of Gasoline, Diesel and Industrial IC Engines. Normally, a valve should rotate during engine run. Rotating valves have high life certainly. Rotating valves have high life certainly. Uniform heating of valve seat surface (means no heat collections local heat areas ), preventing of some carbon adhesions, valve train disturbances and good running surface on the valve tip depend on the valve rotation. Rotating event, if no rotator mounted, happens by normal vibration of engine and also spring strok. The valve do not rotate by deformed or not good weak springs. Valve should be rotated normally, no fast or no slowly. Good springs and rotator (rotocaps) result in normal rotation of valve and no wear on tip or no local heating or burning on seat surfaces. We apply special process on product as per drawing’s description or customer’s requirement like Bi-metal valve, chrome plated on stem, Nitred valve, Seat face induction valve, though pass induction of Tip hadnessâ€Â¦

Valve Seat Inserts

200 - 2,000 Per Piece

200 Piece (MOQ)

The valve seat insert prevents the impact/burying of the valve into the cylinder head. It absorbs a proportion of the combustion heat with which the valve is charged. The valve seat insert gives off this heat to the cylinder head. To meet the different strains, an optimum material composition of the valve seat inserts must be found. Not only must the operating conditions in the engine be considered, but also the machinability of the material for the engine reconditioned. Valve Seats are made from High Quality Chromium and Nickel. Valve Seats ground surface is maintained 15 to 20 microns and face parallelism @ 10 microns. 100% dimensions Inspection and Visual Inspection of Valve seat Inserts. Hardness of Valve Seats must be 30 to 35 HRC. MaterialsIn the most recent engine generations of renowned car manufacturers, valve seat inserts made of sintered material (powder metallurgical procedure) are used. The increasingly high, thermal strain of the seat insert in the combustion chamber can hardly be met anymore by materials from conventional casting processes. For this reason, Motorservice offers sintered valve seat inserts amongst others from two different material combinations, which covers the entire application range of future engines. Sintered Metal Seat Inserts Cast Iron Seat Inserts Production Capacity 30000 pieces per month *Believe in Quality not Quantity

Inlet Exhaust Valve

Get Price Quote

Are you looking for superior quality Inlet Exhaust Valves? We assure to serve you best. We present best quality exhaust valves that are used in Diesel Engines / Marine Engines. Manufactured from high quality raw materials. We maintain international standards of quality that has helped us in garnering large number of customers all over the globe. Valves are made from chrome-silicon alloy steel Stellite ® seated (to operate under high temperature and high stress conditions). Note : Stellite ® is registered trademark of Dellro Stellite, UK.

Hydraulic Lift Non return Valve Seat New Model Long

Get Price Quote

1 Piece(s) (MOQ)

We are offering this hydraulic lift non return valve seat new model long this is suitable for inter mahindra tractor.

Engine Valve

Get Price Quote

100 Set(s) (MOQ)

The inlet valves seal the intake port, through which the air flows into the combustion chamber and exhaust valve control the flow of combustion gases and let them stream out after the combustion cycle.Valves are nitride to increase the exhaustion strength, Chrome plated to increase the wear resistance and Stellited (Seat hard Faced) to get high hot hardness at the seat.

Valve Tappet

Get Price Quote

Based in Gujarat, we are a prominent Exporter and Supplier of Valve Tappet. We source Valve Tappet from one of the leading manufacturers who precisely engineer Valve Tappet in a wide assortment of different specifications. A Valve Tappet is a device for maintaining zero valve clearance in an internal combustion engine. Use of Valve Tappet ensures quieter operation, longer engine life and eliminates the need for periodic adjustment of valve clearance in a machine. We can be contacted for purchasing Valve Tappet as per the requirement at the best market prices.

Engine Valve

Get Price Quote

500 Piece (MOQ)

Anand liner(india)pvt.ltd., iso 9001:2008 certified company and iso 14001 in process, has been manufacturing and exporting engine parts i.e. cylinder liners, cylinder sleeves, air cool block, piston and rings tappets injector sleeve,connecting rod, valve guide and valve seats, since 1981 and has thus acquired an extensive expertise in the production of the above parts. Having based ourselves on the features demanded by large companies, we have all the in-house facilities for centrifugal casting process, induction furnaces, cnc, vmc, honing machines, grinding machines, spectrometer for material analysis and quality lab for surface roughness tester, profile projectors and other necessary measuring instruments. Our keen knowledge of the automotive industry has helped us to develop and supply necessary parts to clients. Our client list includes some of the below mentioned oem's .anand liner(india)pvt.ltd.  has 5 factories (units), for exports and domestic market, - unit 1 = 100% export oriented unit (eou) for cylinder liners, cylinder sleeves and antipolishing rings( for marine applications). - unit 2 = domestic unit for cylinder liners and cylinder sleeves. - unit 3 = valve guide and valve seats for exports market. - unit 4 = air cooled blocks for exports market.

Engine Valves

Get Price Quote

In order to ensure the safety of the products, we carefully store the lot under hygienic conditions and safe environment. Moreover, the lot is stringently and regularly checked by the experts. According to your convenience, to pay for an order, our company can settle on a method of payment. We are familiar with online and offline payment methods. We only want to make payment safe and secure for you. Features : Sturdy metallic structure Precision engineered Long life

Diesel Engine Valves

38 - 95 Per Set

100 Set(s) (MOQ)

Our in-depth knowledge and industrial expertise enable us to offer a distinguished range of Engine Valves. We manufacture these valves using supreme class raw material and sophisticated technology as followed the industry laid norms and standards. In order to deliver flawless delivery at our premises' end, these valves are precisely tested under the guidance of our quality experts against several quality parameters. In addition to this, these valves are widely used in diesel engines as a component.

Engine Valves

Get Price Quote

High quality engine valves manufactured with hot forging process Very precise machining and grinding with OEM specification tolerances using high profile computerized controlled machineriesReplica cartier watches High chromium and nickel based material being used. Specifications EN 52, 214N, SS 316, Incanel and can use any Knock off Patek Philippe material as per specification Special Tip hardening maintained above 53 hrc. Chrome plating, anodizing,Knock off Patek Philippe Phosphating and shot blasting options available Each part is passed through Replica omega for sale value added burnishing process Wide range up to 700 models suitable for worldwide cars, trucks, tractors and industrial engines.

Engine Valves

100 - 1,000 Per piece

Suitable Part for Oil Engine/ Agricultural Engine/ Generator Engine.

Engine Valve

Get Price Quote

100 Pair (MOQ)

We are offering engine valve type : petter av -1 std. Diesel engine inlet and exhaust valve

Motorcycle Valve

Get Price Quote

We feel pride in introducing ourselves as one of the distinguished firms engaged in manufacturing and supplying the best quality Motorcycle Valve. Motorcycle Valve is being manufactured under highly controlled industrial environment. Moreover, our quality auditors keep a strict watch on the entire manufacturing process before the final dispatch.

Valve Seat Inserts

Get Price Quote

Valve seat inserts Nickel and chromium casted valve seats with multiple options as per customer specifications. Seat grinding clearance maintained at 15 microns and face parallelism at 7 microns, Having wide production capacity for valve seats that suits almost every model available worldwide

Valve Tappets

Get Price Quote

Valve tappets, Valve Tappet is small member of engine which have no roller for follow the camshaft lobe, but it is also known as cam follower, Valve tappet is interposed between each camshaft lobe and valve lifting mechanism, it size is depending on engine design.

Two Wheeler Engine Valve

40 - 200 Per Piece

500 Piece (MOQ)

Exhaust Valve

Get Price Quote

5000 Piece (MOQ)

Enhance Engine Performance with Our Premium Exhaust Valves:Explore our selection of high-quality exhaust valves designed to optimize engine performance and reliability. Engineered with precision and crafted from top-grade materials, our exhaust valves deliver efficient gas flow and ensure long-lasting durability. Discover the key features and benefits that make our exhaust valves the ideal choice for your automotive and industrial applications.Key Features:Premium Materials:Our exhaust valves are crafted from heat-resistant alloys, stainless steel, or other high-quality materials to withstand the extreme conditions of combustion. This ensures durability and reliable performance over the valve's lifespan.Precision Machining:Each exhaust valve undergoes precision machining processes to achieve accurate dimensions and tight tolerances. This precision promotes optimal sealing, minimizing the risk of leaks and enhancing overall engine efficiency.Heat Resistance:Engineered to endure high temperatures and harsh combustion environments, our exhaust valves maintain their structural integrity even under extreme heat conditions. This heat resistance contributes to extended valve life.Optimized Gas Flow:The design of our exhaust valves is optimized to facilitate efficient gas flow during the exhaust stroke. This optimization enhances engine performance by reducing back pressure and improving horsepower and torque.Wear Resistance:Special coatings and treatments are applied to enhance wear resistance, reducing the impact of friction and extending the valve's service life. This feature is crucial for reliable, long-term engine operation.Compatibility:Our exhaust valves are designed to meet or exceed OEM specifications, ensuring compatibility with a wide range of vehicle makes and models. This compatibility makes them suitable for various automotive and industrial applications.Corrosion Resistance:Corrosion-resistant coatings or materials are used to protect the exhaust valves from rust and corrosion, especially in engines exposed to moisture or harsh environmental conditions.Reliable Sealing:The valve design and manufacturing processes prioritize reliable sealing, preventing exhaust gases from leaking into the cylinder during the compression stroke. This contributes to improved engine efficiency and performance.Applications:- Automotive Engines- Motorcycle Engines- Marine Engines- Industrial Engines- Power Generation- Agricultural Machinery

Engine Valve

Get Price Quote

Owing to our rich industrial experience and in-depth knowledge, we bring forth a wide assortment of Engine Valves. Our Engine Valves are manufactured from superior quality chrome plating that ensures strength and durability. We make them available in different dimensions and specifications so as to meet the variegated industrial requirements. We are a well-known Engine Valve Manufacturer, Exporter and Supplier from Gujarat (India). Backed by a huge distribution network, we can deliver our Engine Valves within a stipulated time frame.

Diesel Engine Valves

Get Price Quote

5000 Piece(s) (MOQ)

As a prominent player in the industry, we present Diesel Engine Valves. We manufacture them in conformity to the set industry standards by making use of unequaled raw material and latest technology. Various dimensions are offered to the customers as per their needs. Strict quality tests make sure they are corrosion resistant, flawlessly finished, widely acknowledged and precisely designed. Our customers can buy them in bulk quantities for cheaper rates.

valve seat

Get Price Quote

We are one of the prominent Manufacturers and Suppliers of Valve Seat. Based at Rajkot, Gujarat, we offer Valve Seat of different specifications and for different applications. We manufacture Valve Seat using the finest grade Cray Cast Iron Alloy as well as Brass Bronze & Copper backed materials. In the Valve Seat, the cylindrical grinding is done to archive geometrical parameters. Our valve guides are hardened up to 210 to 260 BHN. Details : The machining of outer diameter with tolerance 15 to 20 microns and dinner diameter 25 Microns.

Engine Valves

Get Price Quote

IKON Engine Valve

Get Price Quote

We manufacture wide range of valves for all type of 2 wheelers and 3 wheelers, you name it we have it. We are using Valve Steel EN 52 SUH3, SUH11, 21-4N, 21-12N material in production of Engine Valves. Our product has undergone Forging, Turning, Grinding and Heat Treatment. This makes it more durable than any product in the market. We provide oversized stem diameter which helps while fitting, so the engineer doesn’t have to replace valve guide. This saves cost and time in the fitting. We assure that among 1000 sets there will be not a single set which has to be replaced or quality complains WILL NOT COME. We are strictly following OEM Standard. We offer the most reasonable price without sacrificing the quality.Ikon Engine Valves products are easy to fix, time saving while fixing it in the engine because of 100% precision in our products.