Fertilizer Spreader

30,000 - 45,000 Per INR

Khedut Fertilizer Spreader is a modern technology, designed to spread fertilizers in large portions of land with greater ease, efficiency and with uniform spreading.

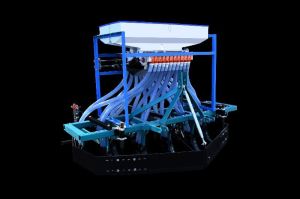

Power Tiller Driven Automatic Seed Cum Fertilizer Drill

Get Price Quote

Best Deals from Fertilizer Machine

Biomass Briquetting plant (Super- 60)

Get Price Quote

The Briquetting Plant is a ram type press designed for continuous heavy-duty operation with two load wheels. One of the load wheels acts as a pulley, and driven by the main motor through a flat belt. Forced lubrication is provided by oil lubrication system which gives a longer life to the bushes.Dry agro - forestry waste as a raw material is fed through the screw conveyor to Kupy by means of vertical screws, with its own-geared motor. It pre-compress and forces the material downward into the feeder box. From the feeder box the material is forced by the Ram through Taper die and due to high pressure & heat, raw material (Biomass) is converted into solid cylindrical briquettes. Finally finished briquettes come out from die holder and passes through natural cooling lines.During Process lignin content in the raw material (Biomass) is transformed into liquid form & acts as a natural binder. Therefore it is called the Binder less Technology. Super-60 Model is ideal for low production and best for waste management in agro and wood industries. If raw material ( Biomass) is available in powdery form, so this smaller model is suitable to convert Briquettes. Application : Biomass Briquetting Plant is for converting agro forestry waste (Bio-mass) to Briquettes (Bio-coal). Production Capacity of Biomass Briquetting plant ( Super- 60) : Output Production Capacity - 600 Kg/Hr Raw material ( Biomass) Specifications : Size of Raw Material - Up to 5mm Moisture contain - Max. 10 %. Output Briquettes (Bio-coal) Specification : Briquettes Diameter / Shape - 60 mm ( Cylindrical Shape) Briquettes Length - Not fixed ( around 1 Feet) Output Production Capacity - 600 Kg/Hr. * Production Capacity :Output capacity is depends on the bulk density of Raw Material. So it will vary with different input raw material.It will be 400 Kg to 600 Kg/Hr. If the raw material is not in powdery form then Hammer Mill is required additionally.Electricity / Power : Total Connected power Load - Approx. 48 HP Practical used Amp. Load - Approx. 40 - 50 Amp Power consumption - Approx. 35 - 40 Unit/MT Individual Electric data : Briquetting Main Ele.Motor - 40 HP Feeding Kupy Ele. Motor - 5HP Screw Conveyor Ele. Motor - 2 HP Lubrication System Ele. Motor - 1 HP Area & Size : Foundation - 12 Feet x 4 Feet Machine Room (For one Machine) - Minimum 20 Feet x 15 Feet Total Area for Project - Minimum 200 M3 or More Silent Futures of Radhe Engineering Co. - Biomass briquetting Plant (Super-60) : Standard genuine parts with applicable MOC and process Compact but ideal design reference to Jumbo-90 Temperature sensors to all bushes to prevent life of bushes. Auto control feeding as reference to main motor load and auto restart VFD to screw conveyor to change speed of feeding

Hydraulic Flange Spreaders

Get Price Quote

Hydraulic Flange Spreaders are used for safety opening pipe flanges. Available in capacities of 5 tonnes and 10 tonnes the versatility of both models enables the user to open flanges up to 92mm thick.l operated with a standard hydraulic hand pump and connecting hose and supplie in a handy steel storage case, hydraulic flange spreaders can be operated individually, or as a pair when opening large diameter flanges. With hydraulic flange spreders it takes minutes open the toughest flanges without the risks of sparks caused by hammer blows and chisels. With the hydraulic power-spreader-Hs 100, a hydraulic cylinder replaces the ratchet handle. A standard hand pump powers 1 power-spreader, or a pair, with ease. Again, you are supplied with 4535 kg (10, 000 Ibs) of force and 76.2 mm (3") of gap ; ample for gasket replacement or turning of blinds. Using the manual power-spreader-MS 100, simply place the tips between the flange faces and turn the ratcheted handle. The ratcheting action is transformed into 4535 kg (10, 000 ibs.) of spreading force and creates up to 76.2 mm (3") of gap. Choose Manual or Hydraulic Lightweight. Only 7.7 kg (17 Ibs). Jaws open parallel. No drift. It stays where you place it. Easy one person operation. Universal. One-size-fits-all. 4535 kg (10, 000 Ibs) applied force at tips. Opens to 76.2 mm (3 inches).

Fertilizer Spreader

Get Price Quote

While the traditional method of spreading fertilizers with hands was more laborious, time consuming and health hazardous, this modern method designed by us is less time consuming and more comfortable and also it does not present any threat to health.They can spread the fertilizer fall on 12 to 14 meter width in field.Their unique distributing system ensures uniform spreading of fertilizers over greater distances.

Plastic Adhesive Glue Spreader

7 Per Piece

fertilizer seed drill

Get Price Quote

All our payment methods are practical and convenient. A method is agreed upon by us with you at the time of undertaking to ensure no confusion or problem arises later on. You can rely on us for delivering the products within the committed time span as we have the best facilities at our end. We have successfully hired responsible team members to keep a vigil eye over the same.

biomass briquetting plant

1,750,000 - 5,000,000 Per Set

* Application Biomass Briquetting Plant is for converting agro forestry waste (Bio-mass) to Briquettes (Bio-coal). * Description of Briquetting Plant ( Jumbo-90) The Briquetting Plant is a ram type press designed for continuous heavy-duty operation with two load wheels. One of the load wheels acts as a pulley, and driven by the main motor through a flat belt. Forced lubrication is provided by oil lubrication system which gives a longer life to the bushes. Dry agro - forestry waste as a raw material is fed through the screw conveyor to Kupy by means of vertical screws, with its own-geared motor. It pre-compress and forces the material downward into the feeder box. From the feeder box the material is forced by the Ram through Taper die and due to high pressure & heat, raw material (Biomass) is converted into solid cylindrical briquettes. Finally finished briquettes come out from die holder and passes through natural cooling lines. During Process lignin content in the raw material (Biomass) is transformed into liquid form & acts as a natural binder. Therefore it is called the Binder less Technology. Jumbo-90 is flagship model in Biomass briquetting industries. Jumbo-90 gives more production and minimum process cost per MT.

Dry Granulator Machine

Get Price Quote

The dry Granulator consists of two motor driven rollers with teeth. This forces the material to be granulated with very low proportion of powder. This is a very sturdy attachment and can be run continuously for granulating tablets / slugs and pellets.

Biomass Grinding Plant

Get Price Quote

Being one of the reputed organizations in the market, we are offering an exclusive range of Biomass Grinding Plant which is made available in several technical specifications. Acknowledge amongst our customers due to its minimum maintenance and efficient functionality, our offered biomass grinding plant is assembled by our adroit professionals with the use of cutting edge technology. Besides, our quality analyst severely inspects this biomass grinding plant against certain parameters of quality. Features: Hassle free performance Durable Easy to operate

Fertilizer Drill

Get Price Quote

Automatic Seed Cum Fertilizer Drill

12,000 Per Piece

5 Piece(s) (MOQ)

Prominent & Leading Manufacturer from Rajkot, we offer Animal Driven Automatic Seed Cum Fertilizer Drill, Animal Driven Automatic Seed Drill, 60Kg Animal Driven Automatic Seed Drill and Animal Drawn Seed Drill. Being one of the trusted firms in the industry, we are highly engaged in providing a unique range of Animal Driven Automatic Seed Cum Fertilizer Drill.Detail:Which Seed for Sowing: Wheat, Ground Nut, Cotton Seed, Castor, Garlic, Maize, Cumin Seed, Soya Been, Sunflower, Paddy (dry Land) All Types Of Grains Cereals & Pulses SeedsNote: Prices without cultivator Rs. 5500 Piece

Fertilizer Injector for Irrigation System

Get Price Quote

Fertilizer Injector

Get Price Quote

Now-a-days by using drip irrigation system, farmers ate producing variery of crops not only of grapes, banana, sugarcane, pomegranate but also of flowers, For this, traditional fertilizer methods are used. In same Places Fertilizer soluble in water are used. For this purpose they use fertilizers tanks or H.T.P. Pumps. Elsewhere fertilizers are supplied by foot pumps also or pumps of 0.5 HP are used, The base for water soluble fertilizers is acid. Hence, all the above equipments become useless by corrossion. For this purpose, a new production called OM Fertilizer Injector has been introduced. Using this injector, we can supply uniform quantity of fertilizers in the entire field. Hence, it is very essential to install OM Fertilizer Injector, The best quality of OM Fertilizer Injector is that it doesnot require any external power. it works in an existing pressure of pumps.

Fertilizer Spreader

Get Price Quote

Khedut Fertilizer Spreader having a modern technology & designed to spread fertilizers in large portions of land with greater ease, efficiency and with unioform spraeding. Steel Conical Hopper spreader equipped with four fins spreading disc for granular or crystalline fertilizers.

Fertilizer Drill

Get Price Quote

Fertilizer drill, Tractor Operated Automatic Seed cum Fertilizer Drill machine’s having 17 teeth , 34 pipes and it height 34 inch (each pipes). It very useful to seeds sowing .

Seed Cum Fertilizer Drill

Get Price Quote

biomass gasification plant BDGP-1000

Get Price Quote

For the optimal generation of tar-free & cost-effective gas, rely upon the BDGP-1000 Series Biomass Gasification Power Plants offered by us. These Plants are designed to impeccability by employing innovative technology.Features of the Plant Tar free producer gas available for process No gas scrubbing finally no waste water generation BDGT gives better and précised process control. Better conversion of various solid fuels to gaseous fuel Total environmental friendly no generation of tar and contaminated water. Steam is not require for gasification Continues operation and operation friendly Fully automatic with skada / plc Multiple fuel options for feed stock Steam coal B GRADE Steam coal C and D grades Steam coal imported Bio –coal / briquettes Wood coal/ charcoal Wood Lignite Applications Hot re rolling mills Refectory & minerals industry Forging industry Metal industry Rubber industry Textile industry Paper and pulp industry Ceramic industry Chemical industry Cement and lime industry Pharmaceuticals Food processing unit Can produce power for every industry and every need

Fertilizer Dryer Drum

Get Price Quote

The fertilizer drying drum machine is used to dry compound fertilizers with required humidity and size of the particles. It not only dries the compound fertilizers but also dries other granular material. The moisture content will be reduced from 5% to 30% of the compound fertilizers whereas while drying bio-organic fertilizer, the moisture levels will be reduced from 40% to 10%. Features High utilization rate of heat energy due to efficient design. Strong adaptability of fertilizers and other materials. Low energy consumption due to small resistance for hot air. Huge capacity of the drying drum. Benefits Reliable operation with high yielding. Ideal for mass fertilizers production. Simple and easy drying process. Low maintenance and repair cost. Lengthy service life. Automation operation with better drying effect.

Seed Cum Fertilizer Drill

24,500 Per Piece

Spreader

Get Price Quote

Fertilizer Injector

Get Price Quote

biomass briquetting plant

Get Price Quote

The biomass briquetting plant is completely eco-friendly technology. Briquettes from Agriculture and industry waste is a completely carbon free as made with binder less technology. The biomass briquettes are easy to maintain and transport. In India these product is more popular than other country. The biomass briquetting plant turns out to be a great substitute of coal. Owing to Subsidy for biomass briquetting plant in India, profit and success on this plant is great. Main concept of this project is to produce the material as a bio-coal.

Animal Drawn Seed Cum Fertilizer Drill

13,500 Per Piece

Brass Urinal Spreader

395 Per Piece

Semi Automatic Briquetting Plant

100,000 Per Piece

1 Piece(s) (MOQ)

Plastic Glue Spreader

Get Price Quote

biomass briquetting plant

Get Price Quote

The biomass crusher cum shredder is a first priority product in biomass briquetting process as per it is accustomed for chop the biomass material into smaller particles and suitable size required by individual biomass briquetting plant. Our crusher for biomass briquetting plant offers defined product output, prescribed by the user and used with all types of biomass material

tractor drawn seed cum fertilizer drill

Get Price Quote

tractor drawn seed cum fertilizer drill, Automatic Seed Drill

biomass briquetting plant

Get Price Quote

biomass briquetting plant, Briquetting Machine, Briquetting Press