Straight Forged connecting rods

Forged Connecting Rods Manufacturers With years of industry experience and rich resources, we at Ganga Forging have achieved an enviable reputation. We are one of the leading manufacturers and suppliers in the market offering a wide array of Forged Connecting Rods. Backed by skilled professionals, our forging is manufactured with the best quality raw materials and advanced technology. Ganga forging is applauded among the clients due to its quality and durability. This is used in different industries like generators, automobiles and diesel engines. Features: • Long service life • Seamless finish • Dimensional accuracy • Weight and size tolerance Manufacturing of Forged Connecting Rods For decades, forged connecting rods are regarded as the quality standards of internal combustion engine. Over the years, production methods of connecting rods have constantly changed. This included forging, hammer forging, press forging, metal powder forging and casting. In the early years of auto industry development, hammer forging was considered one of the best-forging methods. However, in the middle of the twentieth century, due to the higher requirements for quality and tolerance, there was a need to change the forging method. So manufacturers began to use a mechanical press to replace forging hammer. The most effective way to reduce the manufacturing cost was to improve material utilization. Increasing requirements for weight and size tolerance promoted the use of powder forging method. Another advantage besides tolerance was that we could forge connecting rod cover together with the rod. We could open the cover from connecting rod, thus manufacturing cost was saved. In the late twentieth century, forging method developed into “open” forged steel connecting rods. This became one of the strengths of the powder forging. The strength of forged steel connecting rod is higher than powder metallurgy rod. Due to this the engine compression ratio increased. As a result, high strength of forged connecting rod became more satisfactory. This forging method could meet both the strict requirements of weight and size tolerance. Outstanding Quality and Customer Satisfaction We are a renowned manufacturer of the qualitative assortment of Forged connecting rods and much more. These products are marked for their durability and corrosion resistance. We have established an ultra-modern infrastructure unit that spreads across a wide area. The unit is empowered with cutting-edge technology and ultra-modern machinery. This unit helps us in manufacturing the products in a streamlined manner. The units work in close coordination to meet bulk and urgent orders. The demands of clients are met in an efficient and economical manner under the guidance of highly skilled professionals. The products are timely delivered with the assistance of a wide distribution network. Furthermore, we are able to meet the satisfaction of our clients owing to our customized solutions, ethical business practices and after-sales service.

...more

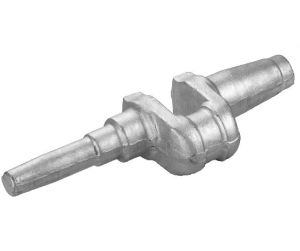

Single Cylinder Crank Shaft

Ganga Forging is one of the most trusted forged crankshaft manufacturers in India. Our services are up to the mark, and we assure quality with all our finished products and components. Crankshafts are the main rotating parts of an engine that are installed on a connecting rod and can convert the up and down movement into a circular movement of the connecting rod. Typically, in the crankshaft manufacturing process, a billet of suitable size is given a heat treatment till the required forging temperature, and then it is successively pounded or pressed into the required shape by pressing the billet between a pair of dies under high pressure. If there are complex shapes or extreme deformations to be achieved, then, more than a set of dies are needed to get the task done and accomplish the right shaping. Crankshafts can be cast or forged.

...more

forged yoke

Yoke Forgings Manufacturers Ganga Forgings is a well-known Yoke forgings manufacturers in India. With us, you get quality yoke pins, shafts, ball, and body. Our forged yoke manufacturing services are acclaimed worldwide and we provide to you high-quality industrial equipment and components. We have an extensive experience of almost three decades in manufacturing for all leading industries. Our customers value us for our commitment to quality as we provide all industrial components finished to the last bit that ensures quality and a long life of components. Ganga Forgings manufactures yoke forgings with expert care and craftsmanship. Our industrial components conform to all quality standards and benchmarks and we are proud to be known as a leading yoke forgings manufacturer around the world. What are slip yokes used for? A slip yoke is an integral component of a drive shaft assembly. The yoke allows the drive shaft assembly to flex or slip within the required application. The component is also used to allow U-joints to rotate smoothly and properly with the drive shaft. Ganga Forgings provides yoke forgings in a vast variety of dimensions as these components cater to the numerous applications that require drive shafts. The successful operation and quality of a yoke forging depend on its use, that is, on the lubrication that is provided during the life cycle of the drive shaft. Lack of lubrication or the use of a dirty lubricant introduces the most common form of failure in the functioning of a driveline, as it causes several stresses along the driveline, that, in turn, cause severe damage to the application. The ideal yoke forgings Ganga Forgings provides the ideal forged yokes for all your industrial needs. For the yokes to function properly, they need to be manufactured with added strength and zero defects. So, we design yoke forgings using the drop forging process. The first step in manufacturing forged yokes is the forging die, which is expensive than the casting process but gives many benefits to the finished product. At Ganga Forgings, you get the most competitive rates and the assurance of quality. With our precision machining method, we then complete the ideal forged yokes for our customers. We are experts in manufacturing forged yokes in India and to our overseas customers as well. If you too think quality matters, you have reached your destination for the best forged yokes in India and abroad. Why Ganga Forgings We at Ganga Forgings cater to all your needs form the simplest samples to the most complex requirements. Our manufacturing process helps us keep quality over everything else. We deliver finished products that are smoothened and tailored to suit your needs. With Ganga Forgings, you get quality assurance with the best products, at competitive prices. We are cost-effective as all our machines and technical equipment are maintained in-house. We cannot rely on a third-party to work with the same dedication and commitment as we do. Contact us with your requirements today!

...more

Forged Trunion Shafts

Shaft Forgings and Forged Shafts Manufacturers We at Ganga Forgings ensure that we provide our buyers with the right length and right diameter so that the purpose of the shaft is fulfilled with competence. We know the value and the importance of each material and how it may affect the functioning of a business. So our clients need not worry about it. We pay significant attention to the kind of material that is used in the making of the shaft forgings and forged shafts. As a leading forged shafts manufacturer, we have greater resilience in our production, which makes our forged steel shaft turnaround very fast. In addition, due to our distinguished characteristics of manufacturing and raw materials, the quality of forged steel shafts that we create are of better quality than shafts machined from other stock. Specifications: Forged steel shafts are created through a manufacturing process that involves the shaping of the shaft Forgings using localized compressive forces. The forging process is initiated when a piece of steel is struck repeatedly with a hammer or squeezed with a press. We have the inventory and capabilities to create forged steel shafts with carbon & alloy steels. Forged Shafts Advantages Our forged steel shafts are manufactured from sound-centered billet which is superior to others in a number of ways which include: • Increased Strength • Greater Ductility • Better Resistance to Fatigue • Diameters ranging from 2 inches to 84 inches and length up to 30 feet Why should we be your first choice? If cutting downtime is critical, and untimely failure is not an option, contact Ganga forging for your organization’s forged steel shaft project needs. The benefits of using forged steel shafts compared to standard bar stock will become immediately apparent. The premium strength of our forged steel shafts makes them ideal for machines and parts that are under high load and pressure. We ensure that the forged shafts we create are made according to the specialized needs of our client. This makes us the most viable and accountable firm among forging shaft manufacturers in India. We are one of the reputed firms engaged in earning our client’s maximum trust by providing a world-class range of products. These products are manufactured using high-grade raw material and are thoroughly checked by our quality controllers, before delivering to our clients. Coordinating with our clients to make a successful partnership is the basic principle on which we work. This allows us to be able to serve our clients with effectiveness and proficiency. We can manufacture custom forged shafts of any material grades as per your requirement. Contact us for your questions regarding forged shafts and get a quote today!

...more

Forged Rolled Rings

Forged Rolled Rings Manufacturers Ganga Forging produces forged rolled rings through a process called ring rolling on rolling mills. The ring rolling process starts with producing a hollow doughnut-like shape by upsetting and piercing a circular shape of metal. The doughnut is then heated above the recrystallization temperature and then placed over the mandrel roll. Then, this idler roll moves consistently towards a drive roll, under pressure, and the thickness is reduced while the diameter is expanded. The rock is first rounded and upset, following which, the workpiece is punched and pierced. Then, the ring rolling process takes place, followed by achieving the desired diameter and sizes. At Ganga Forging, we produce forged rolled rings through standard manufacturing processes that help us maintain the quality of our product. When quality apparatus is needed for the purpose of development of wind turbines or when high-quality gears are required for mechanical parts, the seamless rolled ring forging process is employed for the manufacturing of superior quality of pieces at Ganga Forging. Best Manufacturers of Forged Rings, India We manufacture high-quality seamless forged discs with excellent tensile and yield properties for bearing, gear, and other heavy machinery applications. The open die forging process for manufacturing forged discs produces seamless forged rolled rings with a great internal structural and grain flow along the circumference. This results in forged discs that have a superior yield, toughness, tensile strength, and fatigue resistance. The rolling process that we employ also results in smooth surfaces and excellent concentricity. We have all the manufacturing capacity in-house at Ganga Forging and can handle all of your requirements without the need of outsourcing any requirements. We also promise quality and standard components to all our customers. All Kinds of Forged Discs at One Place Ganga Forging can deliver forged discs in all materials, including alloy steel, carbon steel, aluminum, stainless steel, and nickel alloys. If you have requirements for heavyweight forged rolled rings, we can produce according to your size and weight specifications. We can cater to all your industry-specific manufacturing needs on time and with proper quality checks in place. Our products undergo stringent checks for quality so that no loophole exists in our manufactured components. At each step of production, we employ tests and quality checks and deliver only world-class industrial products. We are known by our customers around the world for our integrity and commitment to quality. We manufacture to industry standards and choose our raw materials wisely. If the raw material itself lacks in quality, we will be restricted in the desired quality of our products. We realize this and only partner with the best raw material suppliers throughout the world. Why choose Ganga Forging Ganga Forging is a leading manufacturer of Forged rings, India. We at Ganga Forging can handle all your requirements in-house with our complete tooling and manufacturing equipment. This helps us ensure that quality is intact and that your shipments do not get delayed due to unnecessary hassles.

...more

Forged Flanges

The leading manufacturers of forged crankshaft, India Ganga Forging is one of the most trusted forged crankshaft manufacturers in India. Our services are up to the mark, and we assure quality with all our finished products and components. Crankshafts are the main rotating parts of an engine that are installed on a connecting rod and can convert the up and down movement into a circular movement of the connecting rod. Typically, in the crankshaft manufacturing process, a billet of suitable size is given a heat treatment till the required forging temperature, and then it is successively pounded or pressed into the required shape by pressing the billet between a pair of dies under high pressure. If there are complex shapes or extreme deformations to be achieved, then, more than a set of dies are needed to get the task done and accomplish the right shaping. Crankshafts can be cast or forged. Forging has some benefits over the cast crankshaft, such as- • Forgings are stronger – Because of the hot and cold working that lacks in a cast crankshaft, forged crankshafts are stronger and more durable. Forging ensures a higher strength of parts and components. • Forgings are inexpensive and reliable – There are a number of possible casting defect that can seep into your crankshaft. Since hot working departs t the product qualities like- resistance, ductility, and strength, crankshafts that are built by expert forged crankshaft manufacturers are reliable and inexpensive as they need lesser controlled processes and inspection. • Uniform heat treatment response – Castings need a control over the melting and cooling processes for the fear of alloy segregation. Consequently, this leads to a non-uniform response to the heat treatment that can affect finished parts. Forged crankshafts respond predictably to heat treatment and thus ensure better dimensional stability. The forged crankshaft manufacturers that know their craft well, will always give you the best guidance for your industrial requirements. Experienced manufacturers of Forged crankshaft, India Ganga Forging has a rich experience in manufacturing and delivering forged crankshafts in different sizes. We also specialize in crafting custom forged crankshafts with any suitable material. The experts at Ganga Forging, the leading forged crankshaft manufacturers, can assist you in determining which material can be the best suitable for your needs. We have an experience of about three decades in manufacturing for industries worldwide. Our quality analysts assure the best of products for your industrial needs. We have assisted all major industries such as- construction, railways, automotive, agricultural, and valve industries. Our clients are always satisfied with our services as we work to ensure their needs are fulfilled and their expectations are exceeded. Automotive crankshafts are exposed to enormous forces and forging gives them the required strength. We at Ganga Forging are the forged crankshaft manufacturers that give them the precise machining that makes them function well under the enormous force and pressure. Entrust your requirements with the leading Forged crankshaft manufacturers

...more

Forged Crankshaft

The leading manufacturers of forged crankshaft, India Ganga Forging is one of the most trusted forged crankshaft manufacturers in India. Our services are up to the mark, and we assure quality with all our finished products and components. Crankshafts are the main rotating parts of an engine that are installed on a connecting rod and can convert the up and down movement into a circular movement of the connecting rod. Typically, in the crankshaft manufacturing process, a billet of suitable size is given a heat treatment till the required forging temperature, and then it is successively pounded or pressed into the required shape by pressing the billet between a pair of dies under high pressure. If there are complex shapes or extreme deformations to be achieved, then, more than a set of dies are needed to get the task done and accomplish the right shaping. Crankshafts can be cast or forged. Forging has some benefits over the cast crankshaft, such as- • Forgings are stronger – Because of the hot and cold working that lacks in a cast crankshaft, forged crankshafts are stronger and more durable. Forging ensures a higher strength of parts and components. • Forgings are inexpensive and reliable – There are a number of possible casting defect that can seep into your crankshaft. Since hot working departs t the product qualities like- resistance, ductility, and strength, crankshafts that are built by expert forged crankshaft manufacturers are reliable and inexpensive as they need lesser controlled processes and inspection. • Uniform heat treatment response – Castings need a control over the melting and cooling processes for the fear of alloy segregation. Consequently, this leads to a non-uniform response to the heat treatment that can affect finished parts. Forged crankshafts respond predictably to heat treatment and thus ensure better dimensional stability. The forged crankshaft manufacturers that know their craft well, will always give you the best guidance for your industrial requirements. Experienced manufacturers of Forged crankshaft, India Ganga Forging has a rich experience in manufacturing and delivering forged crankshafts in different sizes. We also specialize in crafting custom forged crankshafts with any suitable material. The experts at Ganga Forging, the leading forged crankshaft manufacturers, can assist you in determining which material can be the best suitable for your needs. We have an experience of about three decades in manufacturing for industries worldwide. Our quality analysts assure the best of products for your industrial needs. We have assisted all major industries such as- construction, railways, automotive, agricultural, and valve industries. Our clients are always satisfied with our services as we work to ensure their needs are fulfilled and their expectations are exceeded. Automotive crankshafts are exposed to enormous forces and forging gives them the required strength. We at Ganga Forging are the forged crankshaft manufacturers that give them the precise machining that makes them function well under the enormous force and pressure. Entrust your requirements with the leading Forged crankshaft manufacturers

...more

Forged Clamps

Forged Clamps Manufacturers Ganga Forging can deliver you forged adjustable clamps that can instantly adjust to heights without blocks or shims. C Clamps, also called G clamps are the most commonly used clamps in woodworking. The structure of most of the clamps comprises of a sliding cross pin handle or wing nut used for tightening of the clamp. We manufacture certain heavy-duty forged clamps that have screws ending in a square head. In these clamps, the tightening is done through a wrench. There is a swivel pad at the end of the screw which enables for the positioning of the clamp on non-parallel jobs and thus prevents the marring of the work. Also, some other C clamps that are designed for heavy-duty applications do not have swivel pads. Ganga Forging can help you with all your clamp forgings needs. Our superior quality comes at inexpensive prices and we deliver all components quickly. Clamps Forging process C-clamps consist of four parts essentially- the screw, the frame, the handle, and the swivel pad. The frame is the main component of the clamp and is made of stampings, drop forged steel, and castings. Steel forging, generally, provides the most strength in forgings. Ganga Forging gives you the option of getting your clamps customized for any dimensions to suit your requirements. We deliver quality products at competitive prices. The benefits of Clamp Forgings There are numerous benefits of clamp forgings. Go for forged clamps if you want to enjoy the following benefits- • Strength of clamps – Forging improves and provides better mechanical qualities to all your industrial products. It improves their property of ductility, fatigue and impact resistance. This is because forging refines and direct the flow of grains according to the shape of the clamps. • Savings on cost – Forging reduces the weight of the material required to manufacture a component substantially, which, in turn, reduces costs. Also, the manufactured pieces have to be less machined and less material is needed for their cleaning in the end, thus providing even more cost reductions. • Customizations – The shapes and sizes of components can be customized according to customer’s needs. The design of the shapes has versatility so that they can be forged right from rings and bars to complex industrial components. Ganga Forging- Your go-to Forged clamps manufacturer At Ganga Forging, we make sure that your clamp forgings are delivered on time with the guarantee of quality. We have been serving leading sectors with industrial equipment for three decades now. Our wealth of experience helps us to understand your requirements and provide customized products to suit you. Our preference and planning for in-house tooling enable us to make rapid delivery of your parts, whether for sample pieces or for mass productions. We consider our competitive pricing as our selling point. We ensure that we deliver the best quality to our customers worldwide within cost-effective models of pricing. Contact Ganga Forging today with all your requirements.

...more

Blind Flanges

Blind Flanges Manufacturers Blind Flanges are the plates used for covering and closing the ends of pipes. These have all relevant boltholes, but no centre hole. The connection of pipes, where the connecting components have flanges through which they are bolted together, is called a flange joint. Blind flanges are used to seal the ends of piping systems or pressure vessel openings. Most commonly, blind flanges are used for testing the flow of a certain gas or liquid through a pipe or a vessel. Blind pipe flanges are popular as they allow for easy access to the inside of a pipe, in cases where work needs to be done inside the line. These are also used for high-pressure applications. Ganga Forging provides blind flanges in all material grades, sizes, and specifications, suited to your industrial requirements. We provide blind pipe flanges with a raised face, RTJ face, or flat face, as per your needs. Ganga Forging manufactures blind flanges in all steel material grades, such as stainless steel blind flanges, carbon blind pipe flanges, and alloy blind flanges. Our in-house tooling and manufacturing apparatus allows us to cater to your requirements promptly and cost-effectively. We deliver blind flanges to all leading industries like pipe engineering businesses, public services and governments, waterworks, shipbuilding, power generation, pharmaceutical plants, oil refineries, and petrochemical sector. Our blind flanges are engineered with precision using latest technologies for designing and manufacturing industrial components. We use quality raw material from suppliers who are globally acclaimed. Get quick delivery of Blind Flanges Ganga Forging is a leading manufacturer of blind flanges offering immediate delivery programs to its customers worldwide. We equip our blind flanges with female threads and also supply them with or without the hub as per our customer’s needs. We provide our customers with prompt delivery services. We package our products with utmost care to prevent any damage or marring during shipping them to remote locations and far-off countries. Quality assured Blind flanges With Ganga Forging, quality comes along with the products you asked for. We follow industry-specific quality standards religiously, and therefore, do not allow any mistakes or faults in our products. At Ganga Forging, the flanges and fittings are all inspected for quality at several stages of their manufacturing. We start by testing the raw material and then move on towards strict testing and quality assurance mechanisms as the products near their finishing stage. Manufacturing industrial parts are no cake-walk. Experience matters a lot while producing these parts, and they can cost a lot if there happens to be any room for faults. Entrust us with your requirements as we have close to three decades of experience in delivering industrial parts to our customers all over the world. Our customers vouch for our services and praise us for our commitment to quality. Join hands with a leading manufacturer of blind flanges. We can provide you with technical expertise in manufacturing at competitive prices. Contact us with your requirements today!

...moreBe first to Rate

Rate ThisOpening Hours