Batch Type Ball Mill

Get Price Quote

Specification :- We have accomplished ourselves as a foremost manufacturers, exporters as well as supplier of the ceramic Batch type ball mill to reputed client. We are one of the popular industries for manufacturing of great consistence the batch type ball mills manufacturer worldwide. Besides, continuous batch type ball mill is mostly used for the grinding coarse feed to obtain great powder in the single continuous functions throughout a ball mill. There are several kinds of size models is accessible with us that have various capacity of function through its size. Along with rich industry sense in this field, we are offering optimum quality of Ball mills. Features :- Robustness, High durability, Accurate dimensions, Abrasion resisting, Easy to Operate Low Maintenance, Economical, Excellent Performance, Easy Installation Application :- Food & Spices, Pharma, Chemical, Minerals, Guar Gum, Starch, Pigment Colors, Dyestuffs - Fertilizer - Insecticides – Pesticides & etc.

Mild Steel Ceramic Ball Mill

200,000 Per Piece

1 Unit (MOQ)

Best Deals from Grinding Mill

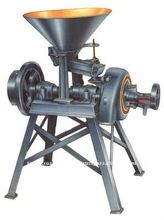

Regulating wheel grinding mill

Get Price Quote

Maize Grinding Mill

Get Price Quote

Raymond Mill

Get Price Quote

Raymond mill is a commonly used milling equipment, mainly used for barite, calcite, feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate ore, gypsum, glass,

corn grinding mills

Get Price Quote

Two long brass, special design of steel hopper, red thrust handle, Zink plating bolt & nuts, extra finishing of color is our speciality. Crust plate is the heart of corn mill. As per below designed crust plates find parallel therefore you can get maximum average of output only in our mill.

Hammer Mill

Get Price Quote

We offer hammermill. Specification: crushtech hammer crushing mill the material from fine to course in bulk, these machines can be provided with cyclone, dust collector for avoiding pollution, easy collection at discharge end & avoid wastage of materials. The grinding chamber of hammer mill is lined with heavy steel liners, which protects the body from wear and tear. A balanced rotor in hammer mill with a set of swing hammers accelerates the grinding process. Working principle: material is feed into the hammer mill from the top and falls into the grinding chamber. The material is contacted by a series of hardened steel hammers rotating at high speed. The material is ground by repeated contact with these hammers, contact with the walls of the grinding chamber, and particle to particle contact. The material remains in the hammer mill grinding chamber until particles become small enough to pass through the perforated screen that covers the bottom half of the grinding chamber. Advantage: • interchangeable screens in numerous sizes to produce the exact & different particle size as desired • easy to change screens in a variety of sizes • cold, dust free & silent running. • low specific power consumption, increased production leading to faster return on the investments. • durable long life • low temperature rise for heat sensitive materials • pollution free working due to properly designed cyclone. • no rcc foundation is required if fixed on a specially designed avm pad frame. application: crushtech hammer mills are used for a wide range of application e.g. Chemicals, stones, minerals, poultry feeds, food products, spices, molding powders, dry soap, charcoal, tea, coffee, etc. Outstanding features include improved grinding efficiency, accurate and consistent product grinding, low specific power consumption, low temperature rise for heat sensitive materials

Ball Mill

Get Price Quote

Ball Mill is used to reduce the particles with help of grinding media. We manufacture, export and supply premium quality Ball Mill in India. Manufactured with rubber line, mild steel and stainless steel, our Ball Mill is widely appreciated for its durability and high performance. The Ball Mill is available in different specifications as per the requirements. Construction : Our Ball Mill consists of cylindrical shell made out of mild steel sheet with or without lining of steel or rubber as per the application. The end plates are designed to make sturdy with stiffeners in order to withstand the rotational load of the loaded ball mill. The Ball Mill is driven by pinion gear which drives the ring gear which is fitted on the drum of the ball mill. The pinion gear is coupled to the gear box which is coupled to the motor to ensure trouble free performance. Bolted Flange covers are provided on the square opening of the Ball mill for loading and discharge of the material.

Colloid Mill

Get Price Quote

Colloid mill is an ideal and perfect homogenizer-cum-emulsifier. It finds its application in various processes like grinding, homogenizing, emulsifying, dispersing, mixin, extracting etc., catering to the needs of several industries, such as 1. Pharmaceutical industry. 2. Food, dairy, sweetmeats and confectionery industry. 3. Chemical industry. 4. Paint industry. 5. Textile industry. 6. Cosmetic and detergent industry 7. Rubber industry 8. Sausage production and meat packing industry 9. Starch industry. 10. Paper industry outstanding and rigid design criteria combined with excellent quality of workmanship of colloid mill automatically ensures superior end product. It is suitable for small, medium, as well as large batches of production.

Attrition Mills

Get Price Quote

The Distinctive Principle of ULTRAFINE GRINDER is based on a high Air throughput in the Grinding area. This high Amount of Air is converted in to A Tremendous Turbulence by the Rotating & Stationary parts of the Machine as well as by an appropriate Guidance of the Air stream in the Mill. The numerous Air Whirls in the Grinding chambers accelerate the Product up to the High Velocity of the Air. The Direction & The Speed of the particles is suddenly changed within extremely short periods. As a result of this principle the particles crash against each other so reaching a careful disintegration in high Air stream. A small percentage of grinding taking place by in pact with the rotating or stationary part of the Mill.. The Creation of numerous air whirls in the single grinding chamber their increased turbulence by the inner grooved liner & the pulsation of the high air velocity make it Micronics.

batch ball mill

124,000 - 125,000 Per Piece

Corn Grinding Mill

Get Price Quote

Corn Grinding Mill “Atmak” brand grinding mills comprises of three types: 1. 1A Corn Grinding Mill. 2. 2A Corn Grinding Mill. 3. A-11 Corn Grinding Mill. We are in business of manufacturing corn grinding mills since 2 decades ,thus having a vast experience in this field and by using the advanced technology we are capable enough to make high quality products. And also our supervisors keep an eye over the entire production process so as to maintain quality of all the products. Our every grinding mills are well tested before going for the final dispatch. The Process of crushing is done by steel disc, the steel disc can be easily change from smooth to serrated edges depending upon types of material being crushed. The main advantage of this mills are a. Low power consumption. b. Contamination free grinding. c. Ensure extremely short grinding time. d. Less noise. e. Low operating cost. f. Easy to maintain. Application 1. To grind corn, flours , etc. 2. Wet as well as dry products can be grinded.

Grinding Mill

Get Price Quote

We have occupied a very spectacular place among all the leading Grinding Mill Manufacturers and Exporters. Our Grinding Machinery is manufactured by highly skillful technicians. Our Grain Grinding Mill is a superb blend of high performance and long lastingness. Our Grain Grinding Mill requires very less maintenance and is easy to use. So feel free to purchase our matchless Grain Grinding Mill at very low and attractive price. Corn Grinding Mill Two long brass, special design of steel hopper, red thrust handle, Zink plating bolt & nuts, extra finishing of color is our speciality.Crust plate is the heart of corn mill.As per below designed crust plates find parallel therefore you can get maximum average of output only in our mill. Danish Type Grinding Mill "Danish" type grinding mills are having one ball bearing on pulley side and one ball bearing in the other side.The position of three bearing of our mill are standing in one center, as per below design. Rice Huller With better working methods, greater technical skill, and reduced expenditure, this "Rice Huller", one of India's finest finished products, in spite of its high standard, is yet within the reach if every rice miller.Our huller are of quality materials and robust construction being meant for years of trouble free service at full capacity.Capacity of hulling varies according to variety, mature, shape, degree of dryness, climate and weather. Necessary Precautions : When ever you open the mill, clean off the flour which may have coagulated around the fixed stone, so that there remains no possibility of the stone get damaged.Do not grind the stones, without feding into the mill, if you do so, you will make of the stones weaker. Note : Mill hopper packing will be given separately as per your instruction. Quality can not be explained orally or not on the paper. It can be found after practical use of machine.

Corn Grinding Mill

Get Price Quote

We are the prime Exporter and Supplier of Corn Grinding Mills. These Corn Grinding Mills provided by us are comprised of special design of steel hopper, long brass, zink plating bolt & nuts, red thrust handle. Our Corn Grinding Mills come in perfect finish and offer durability. Our 1A Corn Grinding Mills are high performance and are affordable too. Features Durable High performance Low maintenance Economic Suitable For Dry As Well As Wet Grinding Of Corn Maize Rice Wheat Cassava Coffee Cocoa Spices etc.

Hydraulic Nut Splitter

Get Price Quote

Our company is engaged in manufacturing and supplying precision engineered Hydraulic Nut Splitter. Our Hydraulic Nut Splitter is appreciated for its efficient in cutting even the hardest nuts. It ensures maximum safety from sparks, flames and volatile surroundings. Applications of Hydraulic Nut Splitter include service trucks, tank cleaning, piping industry, petrochemical, steel construction, mining, etc. Hydraulic Nut Splitter is available in a wide range of models to suit all the requirements of our customers.

Danish Type Grinding Mill

Get Price Quote

Majorly used in agricultural mills for grinding corn, our Danish Type Grinding Mill is popular across the globe. Our Corn Grinding Mill is noted for its compact design, durability and hygienic processing. As a reliable Manufacturer, Exporter and Supplier from Gujarat, India, we ensure customers obtain their order of Grinding Mill within stipulated time. Buyers can acquire the Danish Type Grinding Mill at market leading prices.

Corn Grinding Mill

Get Price Quote

Corn Grinding Mill that we offer is designed by experts and is highly appreciated in the market for its production efficiency. Manufactured to meet the industrial standards, the Corn Grinding Mills are fitted only with components of high quality to enhance their functioning as well as service life.

TV Satellite Splitter

45 Per Piece

500 Piece (MOQ)

Corn Grinding Mill

Get Price Quote

Corn Grinding Mill, Slow Speed Diesel Engine, belt driven centrifugal pump

DC REVERSE TAP AND SPLITTER

Get Price Quote

10 Piece (MOQ)

Features: Items are checked by fully automatic Synthesized PC Based Vector network Analyzer (1300 Mhz.) Final Production Graph Available on Request High Quality "F" Type Connectors Standard Taps & Splitter In High Port To Port Isolation & Excellent Return Loss Made With Key Components From Japan Splitters Are Available In One Port Power Pass & All Port Power Pass Taps & Splitter In Power Passing Up To 15 Amp. Have Special Design Power Passing Coils With Perfectly Matched Micro Henry Which Does Not Disturb Rf Signals While Trans Mitting A.C. Current Along With At Also Avoids Hum Modulation. Powder Coated Graded Aluminium Die. Cast Construction For All Weather Protection. Ready to Digital Frq. Band Outdoor Tap & Splitters are 100 % Waterproof

Corn Grinding Mill

Get Price Quote

Corn Grinding Mill, Slow Speed Diesel Engine, high speed diesel engine

posho mill

Get Price Quote

Maize Grinding Mill

Get Price Quote

Maize Grinding Mill, Diesel Engine, Pumping Set, Generator Set

Lab Ball Mill

Get Price Quote

Lab Ball Mill, Pugmill, dustpan mill, Muller, Attritor

Hydraulic Stone Splitter Machines

Get Price Quote

Hydraulic Stone Splitter Machines

Grinding Mill

Get Price Quote

Grinding Mill, Petrol, Kerosene Engines, Cylindrical Roller Bearings

Grinding Mill

Get Price Quote

Grinding Mill, afridev deepwell hand pumps, Slow Speed Diesel Engines

Grinding Mill

Get Price Quote

Grinding Mill, auto rickshaw, Generators, Flour Machine, Diesel Engines

Ball Mills

Get Price Quote

Ball Mills, Autoclaves, Vessels, vacuum dryers, Ribbon Blenders, Reactors

Grinding Mill

Get Price Quote

Grinding Mill, diesel engine pump, Generator