Hydraulic Pump Balancing Tube MF245

Get Price Quote

1 Piece(s) (MOQ)

Product Code : B4111 Brand Name : Bon Product Specification Hydraulic Pump Balancing Tube MF-245 Has Part No. 1686740M01

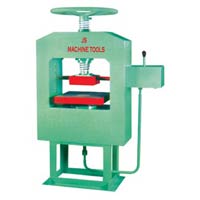

MS Hydraulic Presses

500,000 Per Piece

Best Deals from Hydraulic Machine

Hydraulic Punching Press

40,000 Per Piece

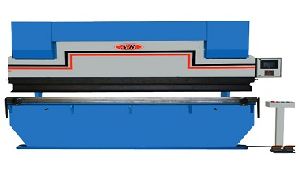

Variable Rake Angle Hydraulic Shearing Machine

Get Price Quote

1 Piece (MOQ)

Get access to the highly acclaimed Variable Rake Angle Hydraulic Shearing Machine that we present. Available under the brand of "ANOX", the Variable Rake Angle Hydraulic Shearing Machine comes with Electric Switch on the panel box. This arrangement of the switch and box reduces cutting load of the sheet considerably. Features : 400 / 440 Volts, 3 Phase, 50 Hz Power Supply.

Inclinable Power Press

Get Price Quote

FMT ®brand Heavy Duty mechanical Power Presses are coming in "C" frame versions from 5 tons to 200 tons capacity in most economical type of construction with several std./optional features such as manual/auto lubrication systems, knockouts electronics safety, Single/Double or Un-geared versions as also Pneumatic feeders/straightness & die-coilers for automatic Purpose. FRAME: The frame is fabricated from solid steel plate with heavy cross ribbing, the structure is designed for perfectly balanced distribution of stress over the cross section eliminating deflection & vibration, in result increased tool & machine life. CLUTCH: The Clutch is made of special alloy steel, The pin / rolling key is manufactured from W.P.S. / EN24 material & with proper heat treatment to ensure trouble free long life & give continues stroke for mass production. CRANK SHAFT: The Crank shaft is made of special alloy steel & precisely machining it to grind finish & fitted in Graded Gun-Metal Bushes for smooth working, longer life & accuracy. ADJUSTABLE STROKE: The unique feature of adjustable stroke enables the press to perform all kinds of operations by employing short stroke for blanking and forming operation. LUBRICATION: An efficient shot lubrication system has been provided for lubricating the sliding surfaces and moving parts. The lubricant is applied by hand pump.Oil cups & Grease point are provided for lubricating the sliding surfaces & moving parts. 50 ton & above Hand operated pump provided. Also Automatic lubrication system offered against request. RAM SLIDES: Ram Slides is made of high grade heavy duty cast iron & properly seasonal & fitted with Hylum Sheet on back side for friction free travel through slides, ensuring longer life of die and easy operation. FLYWHEEL: Properly sized flywheel is made of high grade cast iron, for storing and releasing adequate energy for the pressing operation, and properly balanced for smooth running. BED: Bed is made of high grade heavy duty cast iron & properly seasoned & properly aligned with ram to obtain high accuracy and precision press operation. GEARS: The Gears are made of steel cast or fabricated. Gear teeth are generated by precision hobbing machine.

Hydraulic Shearing Machine

Get Price Quote

Hydraulic Shearing Machine:Mainly Used for Cutting Heavy Coil, Plain Sized Sheet Plate. Range : 4mm to 30mm and Length from 2000mm to 5000mm Version NC PLC.

Hydraulic Press H FRAME TYPE

Get Price Quote

Although Advanced Machine Design has a wide variety of hydraulic presses for many different applications; our hydraulic press designs can be broken down into basic categories to include: two post presses, four post Presses, C-frame presses, vertical presses and horizontal hydraulic presses. The most common press design is the four post hydraulic press. This design is the most versatile as a result of having no size limits, and can be adapted to nearly any process. The four post press design can be configured in a vertical or horizontal position as the process and space available dictate. Precise control Technologies ensures that the four post presses are precise and efficient. Operator access is allowed from all four sides of the hydraulic press so it is very well suited for many different applications. The C-frame press derives its name from the shape of the frame. The primary advantages to the C-frame design are an open work area and increased accessibility. The C-frame press features become even more advantageous when multiple presses are used for progressive operations with automated material handling moving parts from press to press. The C-Frame hydraulic presses, however, are generally limited in maximum tonnage due to the design.The two post hydraulic press is basically a hybrid of the previous two designs. It has good accessibility of the work are for the operator and maintenance personnel while generally allowing for higher tonnage ratings than the C-frame press. Advanced Machine Design Company utilizes over 26 years of engineering knowledge and experience to design and manufacture heavy duty state of the art hydraulic presses. Our presses are available in standard designs or can be customized to individual specifications. Advanced Machine Design Company Hydraulic Presses can be supplied with entry and exit automated material handling with the value added of purchasing an entire turnkey system from one vendor. Standard Press Features: Optional Accessories: 1. PLC Control with digital operator interface2. Meets or exceeds OSHA regulations for safety3. Heavy duty industrial design with 4 to 1 safety factor4. Guarding to individual specifications with E-Stop circuits5. Minimal deflection design6. Overload protection7. NEMA rated panels8. Oil cooler9. JIC/NFPA standard components10. IEC rated electric components11. Full tonnage throughout stroke or cycle 1. Light curtains2. Pressure strips3. Remote system monitoring4. Remote diagnostics5. Die tables6. Die loaders7. Die clamping8. Die storage9. Local or centralized controls Special Feature: These presses offer maximum access to tool area for tool changing & component feeding Applications Slide guidance can be either twin pillars or face slide. Hydraulic power pack is inbuilt & all valves are manifold mounted for easy & quick maintenance & a pressure relief valve protects against overloading of the press. Applications: Cold & warm forging Blanking & Punching Riveting Stamping & Pressing Powder Compacting Other Applications i.e. FRP, SMC, DMC Rubber & Plastics etc.

Hydraulic Press Brake Machine

200,000 Per Piece

1 Piece(s) (MOQ)

Hydraulic Rubber Moulding Presses

150,000 - 1,000,000 Per Piece

1 Piece(s) (MOQ)

Hydraulic Thread Rolling Machine

Get Price Quote

We are one of the leading manufacturers and suppliers of hydraulic thread rolling machine, located in rajkot (gujarat). We are known for supplying commendable quality of hydraulic thread rolling machine to our customers. We use finest quality of raw material to manufacture hydraulic thread rolling machine. Our product is not only durable but also very efficient. features : robustness advanced functionality unsurpassed resistance to corrosion

Pillar Type Power Press

Get Price Quote

Pillar type power press Gears are of steel cast fabrication. Gear teeth are generated by precision hobbing machine. Table and ram are made of high grade heavy duty cast iron & properly seasoned. They are perfectly aligned to each other to obtain high accuracy & precision press operation.

hydraulic honing machine

195,000 Per Piece

1 Piece (MOQ)

Hydraulic Press Brake Machine

500,000 - 3,000,000 Per Piece

1 Piece(s) (MOQ)

Extra Rigid Plate,Interlocked Plate Fully Steel Body Structurel Nc & Cnc- Synchro Machines.Pressing Die Tools Made From En Series.Hydraulic &Electricals Will Be International Makesrnyuken,Polyhydron,Rexroth,Veljan Abb,L&T Etc.

Hydraulic Bending Machine

501,000 Per Units

1 Units (MOQ)

Hydraulic Accessories

Get Price Quote

We are a perfect source for acquiring superior quality Hydraulic Accessories. We are proficient in manufacturing a wide range of Hydraulic Accessories which are mainly used for the tractor trailer parts. Our Hydraulic Accessories are made in strict adherence to industrial norms which make us a reliable Manufacturer & Supplier in Gujarat, India. Range includes Male Female couplingRubber hoses (available in 500 mm, 1000 mm, 1250 mm, 1500 mm sizes)Steel pipe (available for tractors like Swaraj, Power Trac, Ford, New Holland, Mahindra, L & T etc.)

Hydraulic Accessories

600 Per Set

We offer a wide range of Hydraulic Jack which is provided with integral pumping unit. Hydraulic device can jack up the grain bin to discharge corns to car hopper or roadside, has reliable performance and durable structure. These Hydraulic jacks are manufactured using quality raw materials and are strictly checked with by our experts for its proper working. These high quality Jacks are designed and supplied to ensure durability and efficient performance at affordable price. This Hydraulic Jack is available in various dimensions and is accessed as per client specifications. These are widely known for its durability and quality.

hydraulic cylinder parts

Get Price Quote

Discover our high-quality hydraulic cylinder parts, expertly engineered for precision and durability. Designed to meet the rigorous demands of various applications, our hydraulic components ensure optimal performance and reliability.

Hydraulic Lathe Machine

Get Price Quote

The company is offering light, medium and heavy duty Hydraulic Lathe Machine in order to suit different application purposes of the clients. Fully automatic, our Hydraulic Lathe Machine is acknowledged for its user-friendly interface owing to which the operation of the machine becomes trouble-free. Hydraulic Lathe Machine, we provide, is highly accredited for features like sturdy construction, longer functional life, high-speed performance and space-saving design. Obtain from us, our Hydraulic Lathe Machine at very affordable prices.

hydraulic injection molding machine

Get Price Quote

Hydraulic injection molding machine Mould safety arrangement with low pressure mould safety to avoid damage to the expansive moulds.Larger moulds capacity due to increased opening stroke, mould thickness & space between tie bars.

Toggle Press

7,500 Per Piece

25 Piece(s) (MOQ)

Hydraulic Press Machine

32,300 Per Piece

We have created repute as Hydraulic Press Machine Manufacturer and Supplier in Gujarat, India. The Hydraulic Press Machine, offered by us, is precision-engineered mechanism used in a number of industries for diverse applications. Hydraulic Press Machinees can be acquired in different models and capacities from us. We make available Hydraulic Press Machine at competitive prices, as per the requirements of the buyers. Applications : Electic Motor, Submersible Pump, Ball Bearing Factory, Reparing Workshop, Auto Service Station & Industrial Work, Like Pressubg, Bedning, Straightning, Embossing, Broaching of Steel, Iron, Plastic, Rubber Etc. Parts Details Frame Column and Bottom are fabricated from Heavy Mild Steel. The working table is operated vertically and adjusted by worm winch. Rollers are provided easy heavy work. Cylinder Hydraulic Cylinder is made out of Seamless Pipe with Accurate Boaring. Grinding, Honing and Piston from special Rigid Steel with the same Accuracy, with U-Cups / Chevron Packing and Rubber O-Ring Etc. Socket is provided for DIA - PUNCH work. Hand Pump Double Plunger Pump gives Quick Ram Travel with Low Pressure and Slow Speed Develops with High Pressure Plunger. Power Rack Required Power Pack is provided with Gear Pump, Vane Pump, Plunger Pump. Control Valve, Connecting Hoses Pipes, Pressure Meter Etc. Pressure Adjustments Pressure on Piston Rod can be adjusted from 5% to Maximum pressure by safety valve. System of Operation Hydraulic power press is available in hand operated or motorized operation system.

Plate Bending Machine

Get Price Quote

We are offering plate bending machine. Specifications: the pinch cum puramid principle the machine based on this principle combine the advantages of three roll pyramid type, three roll initial pinch type and four roll pinch type machines. Highest degree of pre-bending can be achieved and only the smallest possible width of flat remains. An error in pre pinching can be corrected even after the shell is completed. It can pre-pinch and roll the plate without removing the plate from machine after first insertion. Inclined movement of bottom rolls provides wider bending span as the plate thickness increases, and better grip in thinner plates. cone bending the machine has inherent feature for conical bending without any extra attachments. The two bottom rolls are inclined by disengaging the dog clutch by lever fitted on the machine. Even pre-pinching of cones can be done. salient features top roll drive for rolling thin plates. Highest degree of pre-bending can be achieved and only the smallest possible width of flat remains. Plate squaring(aligning) arrangement. Small dia. Top roll for small shell rolling (for reduced capacity).

Hydraulic Shearing Machine

400,000 - 3,500,000 Per piece

Hydraulic Arbor

20,000 Per Piece

3 Piece (MOQ)

CNC Hydraulic Press Brake

2,250,000 Per unit

1 unit (MOQ)

Oil Hydraulic Press Machine

Get Price Quote

The body of our Oil Hydraulic Press Machine is fabricated using M.S Steel, piston from Hard Chrome and Wiper on the cylinder top. The production capacity of Oil Hydraulic Press Machine is 1200 per Shift. The tile so produces by Oil Hydraulic Press Machine would be having dimensions like 375mm x 375mm. Specifications : Production Capacity : 1200 per Shift Capacity : Size of Tiles up to- 375mm x 375mm

Hydraulic Press Machine

59,000 Per Piece

1 Piece (MOQ)

pillar press

Get Price Quote

Shailesh brand mechanical Power Presses are coming in both C frame and Pillar type versions from 3 tons to 250 tons capacity in most economical type of construction with several stdoptional features such as manualauto lubrication. systems; knockouts electronics hand safety; singledouble or un-geared versions as also pneumatic feeders straightness and de-coilers for automation Purpose.

Air Compressor Hydraulic Truck Platform

5,500,000 Per Piece

Double Cylinder Hydraulic Press

Get Price Quote

Capacity60/75/100/150/200/250/300/400/500/ & More TonnesFeatures Pressure, Speed, Stroke etc. Adjustable Rigid Frame Structure Wide bed size provided for adequate work space for sheet metal parts or componets Uniform pressure by both cylinders. The machine will be built up as per customer specification OVERALL DIMENSIONS ARE IN mm, APPROXIMATE & MAY BE CHANGED WITHOUT PRIOR NOTICE