CNC Synchro Press Brake Machine

150,000 Per Units

1 Units (MOQ)

Front Cylinder Press Brake

1,500,000 Per Unit

Best Deals from Hydraulic Press Brake Machine

Rear Cylinder Hydraulic Press Brake Machine

Get Price Quote

WELDOR Hydraulic Press Brakes are designed and developed through years of experience in Sheet MetalWorking Machineries.Weldor Hydraulic Press Brakesare developed by keepinglatest technology in mind.Both cylinders aremounted at backside of press Brake andare synchronisedfor parallelism between ram and table,by providing mechanical links connected with cylinder.The heavy duty steelconstruction frame is to so designed to absorb heavy shocks of overload.All welding edges are properly machinedfor weldjoints.The electric controlpanelis fixed on side wallat convenient place for easy reachofoperator.lt includespushbutton pendant andfoot switch.Standard'V'Block&'V'Punchand manually operatedback gaugesystemwhich isfront operatedaresuppliedas standardaccessories.Hydraulic components areofreputedmakelike Vickers,Rexroth,Dowty,Yuken,Polyhydronetc.

Rajesh Machine Tools

500,000 Per Number

CNC Press Brake\

Get Price Quote

Frame is made of steel fabricated construction of interlock robust design. Machines are constructed with safe guard against undesired deflections and breakage.Upper and lower double roller bearing for accurate, rigid and fast beam movement. Complete range of standard in special tool to cover every application. Strong alliance with European top class tool manufacturer. he compact Blocks eliminate the leakage chances and also reduces the hydraulic pipes. This low Noise hydraulic system is placed on the rear side of machine, on top between two side plates.The electric control panel is located on the right hand side of the machine. It is assembled from the internationally reputed parts for consistent performance, reliability and availability, if needed to be replaced.

HYDRAULIC NC PRESS BRAKE

Get Price Quote

STANDARD EQUIPMENT Front Cylinder Mounted Design Powered Depth Y-axis & Back gauge X-axis Servo motor controlled back gauge HIWIN Ball screws & Polished rod with 0.01 mm accuracy Plate Support Arms Germany Bosch-Rexroth Hydraulic Germany EMB Tubing connector Germany Siemens Main Motor Telemecanique/Schneider Electrics Hydraulic & Electrical overload protection Top and Bottom Tooling(86°, R0.6mm) Electronic Foot Switch SAFETY EQUIPMENT Front Cylinder Mounted Design Powered Depth Y-axis & Back gauge X-axis Servo motor controlled back gauge HIWIN Ball screws & Polished rod with 0.01 mm accuracy Plate Support Arms Germany Bosch-Rexroth Hydraulic Germany EMB Tubing connector Germany Siemens Main Motor Telemecanique/Schneider Electrics Hydraulic & Electrical overload protection Top and Bottom Tooling(86°, R0.6mm) Electronic Foot Switch

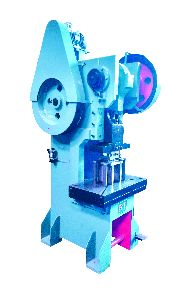

Mechanical Press Brakes

Get Price Quote

Mechanical Press Brakes are designed and developed through structural analysis technique for continuous production, accuracy & repeatability.Frame is made of M S Steel Plate and is of interlocked design. It is strain free and supports Ram & Bed under permissible load condition.Ram is a moving part and holds the V-Punch. It is machined for straightness and parallelism of working surface. Ram is guided and supported by accurately machined guideways.Bed is made of steel plate and accurately grinded. It supports Die and is mounted on lower beam. Bed is bolted to lower beam for easy change.Power is Transmitted to Ram by individual gear drive generating uniform load throughout the length. Gears and pinions are made of high quality alloy steel. Flywheel provides necessary torque during bending operation.Motorised Ram adjustment is provided to facilitate quick bending angle. Spring loaded Dog Clutch is provided for angular Ram adjustment.All Press Brakes are provided with Mechanical high torque friction clutch synchronised with Mechanical Brake ensuring immediate stop of Ram. Clutch fingers are designed in such a way that minimum engaging force is required at pedal. Each moving part is provided with lubrication through hand operated lubrication pump for smooth operation.

Hydraulic Press Brakes Machine

327,000 - 7,500,000 Per Pc.

Hydraulic Press Brake Machine Ranging from 1270 mm width to 6000 mm width. Bending thickness from 0.5 mm to 20 mm.

Mechanical Press Brake Machine

Get Price Quote

Based in Rajkot, we are a prominent Manufacturer and Supplier of Mechanical Press Brake. The design of Mechanical Press Brake is based on innovative engineering. Further, Mechanical Press Brake is configured with advanced technology which efficiently boosts production capacity of unit. Highlights Robust construction Smooth working Efficient design Longer service life Details Frame : Frame is of robust fabricated steel construction of rigid and interlocked design, It is strain- free and supports the ram and bed against undesired deflection under permissible loding condition. Ram and Bed : Made from steel Plates of suitable thickness, machined for straightness and parallelism of the working surfaces. Ram is guided and supported throughout the stroke by accurately machined guided ways. Drive System : Power is transmitted to the ram through two individual geardrives for uniform load distribution throughout the length. This also reduces the torsional stresses on the eccentric shaft. Electric motor used is of sufficient H.P. which reduces slowdown of flywheel and increases energy available per stroke. The gear and pinion are made out of carbon/alloy steel. Ram Adjustment : Motorised ram adjustment through a simple drive mechanism, facilitates quick bending angle adjustment. Angular ram adjustment is made simple by incorporating a spring loaded dog clutch. Clutch and Brake : All series of press brakes are provided with high-torque low-inertia friction clutch, synchronized with heavy duty mechanical brakes ensuring immediate braking of ram on releasing the pedal. Clutch operating levers are designed in such a way that minimum engaging force is required at the pedal. Features Foot Pedal and Die Block Lifting Link. Fly Wheel & Gear Guard. Self Lubrication System. Motor Pully. Stroke counter. Standard �V� Block and Punch. Motor Mounting Bracket. Options Motorised Back Guage. Automatic Lubrication System ee-Belts. Electric Motor & Starter / Control Panal Board. Squaring Guage System. Various type of Die & Punch. Foundation Bolts. All Dimensions are in mm. Power Supply 400/440 volts, 3 Phase, 50 Cycle. As day to day improvements are contemplated for better performance of the machine. We reserve the rights to alter the specifications without prior notice. All the machines undergo a through check-up by our expert engineers before dispatch to ensure their smooth and trouble free operation.

pneumatic press brake

Get Price Quote

Foreman Machine Tools Pvt. Ltd. Press Brakes ore designed and developed through years of experience in Sheet Metal working machines. Kishan Press Brakes are widely accepted in industries for continuous production runs and in areas requiring and repeatability coupled with high production. Is of closed box type steel fabricated, which forms a rigid backbone for the shear and a solid backing for the lower knife. Additional ribs, under the table adds to its strength. CRANK SHAFT & FLYWHEEL SHAFT: Is of best steel, accurately machined and runs in gun metal bearing and all other installed in gun metal bearings. HOLD DOWN: Is of steel fabricated spring loaded ensures uniform pressure through out the cutting length without any slipping irrespecti ve to the sheet. ROLLING KEY CLUTCH: Made of EN-24 steel for positive engagements and continuous operation having three key way. Single rolling key system is incorporated in the machine ensuring easy and efficient working of the machine. DRIVE: Is through "B" Belts on the fly wheel and other chain of job cut gears for smooth running and longer life. BRAKE: Constant spring loaded adjustable brake is provided. BACK GAUGE: In KSML 5, 6, 7 &KSMH 4 to 7 are screw drive where as in KSUG 1 to 4 &KSMH 1 to 3 am of rack pinion type designed to accuracy and easily. STANDARD EQUIP: Side, Back, Front Gauges and Table extension, Fly Wheel and Gear guards, Foot Pedal, Mount and Motor Pulley, Hold Down divide, Set of 4 edge HC HCR Blade and Manual oil Pump for Lubrication. LUBRICATION: For sufficient lubrication oil cups and oil points are provided. BLADE: Is four edged HC HCR provided for longer tool life.

Hydraulic Press Brake

Get Price Quote

One of most important sheet metal forming machinery mainly used to bend sheet plate in different angles. Products like bus & truck body building, electric panel, solar panel, door & window frame and many more.

Press Brake Machine

400,000 Per Piece

pneumatic clutch operated press brake machine

150,000 - 2,500,000 Per Piece

1 Piece(s) (MOQ)

Extra Rigid Frame Structure Press Brake Machine. All Parts Of Machine Are Accurate &precision Machining Before Machine Fitting.All Gears & Shafts Made From Carbon Steel.

Hydraulic Press Brake

400,000 - 3,000,000 Per piece

1 Nos (MOQ)

Semi-Automatic Press Brake Machine

500,000 Per Unit

Hydraulic Press Brake

Get Price Quote

1 Piece (MOQ)

We are offering hydraulic press brake. standard accessories : * main drive motor. * electrical control panel with of 'auto' 'onch' & 'single cycleauto' mode of operation. * pair of foot switches. * pair of lifting links. * pair of sheet supports. * fine stroke adjustment rod with limit switches. * manual back gauge with fine setting. * one suitable 5 way die and blade. * centralised lubrication system with hand pump. optional accessories : * nc - operated stroke (y - axis) control. * nc - operated back gauge and stroke control. * sheet support with swing - away stoppers for front gaufing. * hardened tools & special toolings. * first fill of hydraulic oil. * goose neck punch. * automatic lubrication system. * motorised back gauge with dro.

Hydraulic Press Brake

Get Price Quote

RT Power Press Hydraulic Press Brakes are designed and developed through years of experience in sheet metal working machinaries. RT Power Press Hydraulic Press Brakes are developed by keeping latest technology in mind. Both cylinders are mounted at back side of Press Brake are synchronized for parallesm between ram & table, by providing mechanical links connected with cylinder. The heavy duty steel construction frame is so designed to absorb heavy shocks of overload. All welding edges are properly machined for best weld joints. The electric control panel is fixed on side wall at conventional place for easy reach of operator. It includes push botton pendant and foot switch. Standard “V” block & “V” Punch and manually operated back guage system which is front operated are supplied as a standard accessories. Hydraulic components are of reputed make like Videkers, Rexroth, Dowty, Yuken, Polyhydron etc. Capacities rated for M.S. (U.T.S. 45kg/mm2). Bending capacities stated are only representative and not binding. Allow extra capacity for material inconsistencies, bending conditions. Right to change specification, features without notice reserved. Compliance with safety requirements as per local regulations is responsibility of the user. Standard Features: Electric motor, Control Panel with selection of INCH-ONCE-AUTO Mode of operation. Foot switch. Fine stroke adjustment rod with limit switches, Manual Lubrication, Manual Back Guage, Standard V Block Punch, Insruction Manual. Options: Goose Neck Punch & other tooling (drawing required), Electronic Stroke Counter, NC Operated Back Guage, Automatic Lubrication System. All Dimensions are in mm. Power supply 400/440 volts, 3 Phase, 50 Cycle. As day to day Improvements are contemplated for better performance of the machine. We reserve the rights to alter the specifications without prior notice. All the machines undergo a through check-up by our expert engineers before dispatch to ensure their smooth and trouble free operation. Electricals are not under warranty.

Automatic Press Brake Machine

120,000 Per Piece

Hydraulic Press Brake

Get Price Quote

We are engaged in manufacturing high quality hydraulic press brake to Technically advanced features of our hydraulic press brake make it extremely popular in the global market. The hydraulic press brake. available with us, have welded steel frame made up of IS 262 plates that is ultrasonically tested.

Mechanical Pneumatic Press Brake Machine

850,000 Per Unit

press break machine

Get Price Quote

Approx price: rs 5 lakh unit product details: max sheet width 1 meter, 2 meter, 3 meter, 4 meter, 5 meter, >5 meter automatic grade automatic , semi-automatic, manual control type cnc, non-cnc cutting load 0-30 ton, 30-60 ton, 60-90 ton, 90-120 ton, 120-150 ton, >150 ton we have in store a remarkable gamut of pneumatic press brake for our clients. Developed using premium quality stainless steel, brass and others these offered products conform to the defined parameters of the industry. Our clients can avail the offered products in different sizes and specifications as per their requirements from us.

Hydraulic Press Brake Machine

Get Price Quote

Hydraulic Press Brake Machine, Hydraulic Shearing Machine

Press Brakes

Get Price Quote

Press Brakes, Honing Machine, Hydraulic Press, plate rolling, Power Press

cnc press break machine

Get Price Quote

cnc press break machine, Sheet Metal Bending, Shearing Machine

power press brake

Get Price Quote

power press brake, Agricultural Equipment, Power Press Machines, Power Press

Press Brake Machine

Get Price Quote

A. P. Machine Tools is one of the leading manufacturing & supplying company of high quality press brake machine from India.

Press Brake Machine

Get Price Quote

Press Brake Machine, Roll Forming Machine, Sheet Forming Machine

mechanical press brake machines

Get Price Quote

mechanical press brake machines, Sheet Metal Machine

Press Brake Machine

Get Price Quote

Press Brake Machine, C Type Power Press Machine, Mechanical Power Press

Press Brake Machine

Get Price Quote

Press Brake Machine, Power Press Machine, High Speed Power Press