Toggle Press

7,500 Per Piece

25 Piece(s) (MOQ)

Waste Scrap Baling Press

Get Price Quote

Capacity In Tonnes Chamber Size Bale Size Bale Weight in Kg. Stroke Motor H.P. 15 500x400x900 500x400x450 20 to 35 450 3 25 525x500x1000 525x500x450 35 to 50 550 3 40 550x500x1100 550x500x500 50 to 70 600 3 60 600x500x1200 600x500x500 70 to 100 700 5 75 700x550x1200 700x550x500 80 to 110 700 5 100 750x600x1400 750x600x600 100 to 150 800 5 OVERALL DIMENSIONS ARE IN mm, APPROXIMATE & MAY BE CHANGED WITHOUT PRIOR NOTICE.

Best Deals from Hydraulic Press

Hydraulic Interlocking Paver Press Machine

Get Price Quote

By employing qualitative raw material, our entire range is processed. We, as a promising name, procure it from the trusted places only. Being a quality-conscious firm, we ensure that the offered products comply with the laid industry standards and are of supreme quality. Application : Used for pressing thick steel plate to manufacture thick wall and large diameter pipe. Features : Smooth operation Enhanced working life Robustness

Mechanical Pneumatic Press Brake Machine

850,000 Per Unit

Cotton Baling Revolving Press Machine

Get Price Quote

Mechanical Press Brake Machine

Get Price Quote

DESCRIPTION The Mechanical Press Brake Machine is of robust fabricated steel construction of rigid and interlocked design. It is strain free and supports the ram and bed against undesired deflection under permissible loading condition. Made from steel plates of suitable thickness and machined for straightness and parallelism of the working surfaces. Ram is guided and supported throughout the stroke by accurately machined guide ways. Power is transmitted through two individual gear drives for uniform load distribution throughout the length. We are known as one of the best Press Brakes Manufacturer and not only this we have achieved success through our out of the world machines so we have become one of the most eminent Hydraulic Press Brake Supplier in India.

Mini Hydraulic Press Brake Machine

220,000 Per Piece

1 Piece(s) (MOQ)

Power Press, Gullotine Shear, Press Brake

Get Price Quote

We are offering power press, gullotine shear, press brake 1) mechanical/hydraulic?pneumatic power presses 3tons to 600tons 2) mechancial/hydraulic/nc/cnc gullotine shearing 1200length x 2 mm thickness to 6000 x 25mm 3) mechanical/hydraulic/nc/cnc/ press brake 20t/2000 to 600/6000mtr. 4) press automation systems like de-coiler, streighner, feeder, coiler, chopper etc.

Pillar Type Power Press

Get Price Quote

Pillar type power press Gears are of steel cast fabrication. Gear teeth are generated by precision hobbing machine. Table and ram are made of high grade heavy duty cast iron & properly seasoned. They are perfectly aligned to each other to obtain high accuracy & precision press operation.

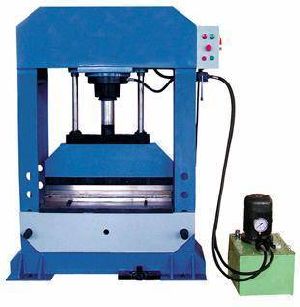

Hydraulic Press

60,000 Per Piece

1 Piece(s) (MOQ)

Hydraulic Press Brake (PLC/NC/CNC Series)

Get Price Quote

SIDDHAPURA Hydraulic Press Brakes are designed and developed through years of experience in sheet metal working machineries. SIDDHAPURA Hydraulic Press Brakes are developed by keeping latest technology in mind. Both cylinders are mounted at back side of Press Brake and are synchronized for parallesm between ram & table, by providing mechanical links connected with cylinder. The heavy duty steel construction frame is so designed to absorb heavy shocks of overload. All welding edges are properly machined for best weld joints. The electric control panel is fixed on side wall at conventional place for easy reach of operator. It includes push button pendant and foot switch. Standard "V" Block & "V" Punch and manually operated back gauge system which is front operated are supplied as a standard accessories. Hydraulic components are of reputed make like Videkers, Rexroth, Dowty, Yiken, Polyhydron etc. Standard Feature Mitsubishi controller with monochrome touch screen. Swivel mounted Hardened & ground ball screw and shaft, liner motion bearing on guide rods AC servo motor for back gauge (x axis) drive High efficient optical liner glass tube scale for Y axis Movable work station with a pair of foot switch A pair of lifting links & sheet support One suitable five way die & punch of EN- 8 or EN 9 Centralized lubrication system with hand pump Ram lifting arrangement Bending chart Mitsubishi Controller & Drives The Controller with monochrome touch screen Manual, Auto, Program mode selection, Stroke Counter through Touch Screen It memorizes 120 (15 Programs and each Program 8 Bends.) Stroke Positions It stores stroke length, height of each bend It allows skipping a step in program if the bend will not required on the job The controller can be connected directly to computer by serial links The controller, Drive and Screen can be offered with customized High efficient Optical Linear Glass Tube Scale for perfect position of Y Axis. Repetitive accuracy with + or 0.05mm Program menus are protected by password Options Multi axis back gauge High speed MPI (Multi Port Interface) link for operation via PC. Anti deflection unit (Manual/Motorized/ Automatic) Hardened & ground tools and special tooling Sliding sheet support with swing away stoppers for front gauging Hydraulic tool clamping Photo electric finger safety guards Ginger guard for back gauge Automatic lubrication system Extra depth of throat Higher speed versions First Fill of hydraulic oil Timing belt drive

C Type Hydraulic Press

Get Price Quote

We make use of the finest grade raw material that reflects in the finished products. Also, we make sure that it is procured from the trusted places only. We are flexible in offering the product basket in the committed time span as we have advanced logistics facilities available.

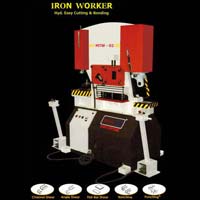

Iron Worker Machine

Get Price Quote

Iron Worker Machine that we manufacture and supply is widely used for easy cutting & bending applications that includes angle cutting, channel cutting, flat cutting, notching, etc. Our Iron Worker Machine features user-friendly electric control panel along with a pair of foot switch for simple operation. We offer manual or hydraulic job clamping device along with our Iron Worker Machine. Furthermore, we offer Iron Worker Machine at the most competitive rates. Standard Features Blade for angle cutting, channel cutting (any one size), Flat cutting & Notching Fine Stroke Adjustment Rod with limit switch Manual / Hydraulic job clamping device Electric control panel Pair of Foot switch Main Drive Motor Optional Features : Blade for Round bar, square bar cutting, 'I' – Bim, Section Cutting Any type of punching notching & bending die First fill of Hydraulic oil Main back gauge

Ironworker Machine

Get Price Quote

To meet the industry demands, we have come up with our range of Ironworker Machine that has been engineered using superlative quality of raw material, under the supervision of experts. Our prestigious customers appreciate this Ironworker Machine for its high performance and sturdy design. It comes with two control foot paddles that offer safe and comfortable functioning of Ironwork Machine. We are the most reliable Manufacturer and Supplier of Ironworker Machine in Rajkot, Gujarat, offering their product at an affordable price.

hand press brakes

Get Price Quote

Our Heavy Duty Hand Press Brake Machines are made from M.S. Material and Mainly useful for any kind of Steel Furniture Industries. It is useful for Half Round and Right Angel Bending. Side Walls: Made from mild steel plate. Vertical and Horizontal supports are provided for more strength. Screws: Made from mild steel with square thick threads. Upper Beam: Made from Heavy Steel Plate. All surfaces are well surfaced to get accuracy. V-Block:Provided with 5 grooves for various sizes of job. Knife: Made from mild steel and sharpened up to 20o after sufficient machining.

Wax Extrusion Press

Get Price Quote

Hydraulic Ram Pressing a Wax Billet against a Heated Die which in turn produces Extruded Wax Shapes. Hydraulic Force for Extrusion is 15 T.

C AND PILLAR TYPEPOWERPRESS

Get Price Quote

FRAME : The Frame is Fabricated From Steel Plates Heavy Wide And Cross Rib Borders. CLUTH : The Clutch is Round Key Type With Single And Continuous Strokes System. The Key And Cluth Ring is Made Of EN 31 Steel And its Parts Are Tempered. GEARS : Gears Are Of Steel Cast Fabrication.Gear Teeth Are Genereated By Precision Hobbing Machine. CRANK SHAFT : Crank Shaft is Made Of A Very Special Alloy Steel It Moves Very Easily In/Gun Metal Buses. TABLE & RAM : Table And Ram Are Made Of High Grade Heavy Duty Cast Iron & Property Seasoned. They Are Perfectly Aligned To Each Other To High Accuracy & precision Press Operation.

cylinder press

Get Price Quote

The Mechanical Press Brake Machine is of robust fabricated steel construction of rigid and interlocked design. It is strain free and supports the ram and bed against undesired deflection under permissible loading condition. Made from steel plates of suitable thickness and machined for straightness and parallelism of the working surfaces. Ram is guided and supported throughout the stroke by accurately machined guide ways. Power is transmitted through two individual gear drives for uniform load distribution throughout the length. We are known as one of the best Press Brakes Manufacturer and not only this we have achieved success through our out of the world machines so we have become one of the most eminent Hydraulic Press Brake Supplier in India.

pneumatic press brake

Get Price Quote

We are offering pneumatic press brake. Weldor press brakes are designed and developed through years of experience in sheet metal working machines. Weldor press brakes are widely accepted in industries for continuous production runs and in areas requiring accuracy and repeatability coupled with high production. 1. Frame: frame is of robust steel construction of rigid and interlocked design. It is stain-free and supports the ram and bed against undesired deflection under permissible load condition. 2. Ram and bed: made from steel plates of suitable thickness. Machined for straightness and parallelism of the working surface. Ram is guided and supported throughout the stroke by accurately machined guideways. 3. Drive system: power is transmitted to the ram through two individual gear drives for uniform load distribution throughout the length. This also reduces the torsional stresses on the eccentric shaft. The gear and pinion are made out of carbonalloy steel. 4. Ram adjustment: motorized ram adjustment through a simple drive mechanism, facilitates quick bending angle adjustment. Angular ram adjustment is made simple by incorporating a spring loaded dog clutch. 5. Clutch and brake: all series of press brakes are provided with high-torque low-inertia friction clutch, synchronized with heavy duty mechanical brake ensuring immediate braking of ram on releasing the pedal. Clutch operating levers are designed in such a way that minimum, engaging force is required at the pedal.

Pillar Type Power Press

Get Price Quote

1 Piece(s) (MOQ)

We offer Pillar Type Power Press. Shailesh brand mechanical Power Presses are coming in both C frame and Pillar type versions from 3 tons to 250 tons capacity in most economical type of construction with several stdoptional features such as manualauto lubrication. systems; knockouts electronics hand safety; singledouble or un-geared versions as also pneumatic feeders straightness and de-coilers for automation Purpose. Steel body fixed, Inclinable type power press Frame : The frame is of all steel construction, fabricated from Rolled steel plates with suitable cross ribbings. Presses upto 30T will be supplied with C.I. legs. proper alignment of the frame is ensured by machining. Clutch : The clutchis of pinrolling key-type. the clutch is rigid and well supported. the clutch gives continuous strokes for mass production. Crank Shaft : Crank shaft is made of special alloy steel machined to close accuracy and fitted in bronze bushes for smooth working, longer life & accuracy. Flywheel : Properly sized flywheel, is made of high grade cast iron, for storing and releasing adequate energy for the pressing operations, and properly balanced for smooth running. Gears : Gear are of steel cast or fabricated. Gear teeth are generated by precision hobbing machine. Table & Ram : Table and fam are made pf high grade heavy duty cast iron & properly seasoned. They are perfectly aligned, to each other to obtain high accuracy & precision press operation. Lubrication : An efficient shot luvrication system has been provided for lubricating the sliding surfaces and moving parts. The lubricant is applied by hand pump. Inclining : Inclinable type presses are provided with inclining mechanism which can be easily det and locked in Mechanism : Position by spanners within minutes. the press ils so designed that even in maximum inclined position, it is stable under heavy pressing load.

Hydraulic Press Brake

Get Price Quote

1 Piece (MOQ)

We are offering hydraulic press brake. standard accessories : * main drive motor. * electrical control panel with of 'auto' 'onch' & 'single cycleauto' mode of operation. * pair of foot switches. * pair of lifting links. * pair of sheet supports. * fine stroke adjustment rod with limit switches. * manual back gauge with fine setting. * one suitable 5 way die and blade. * centralised lubrication system with hand pump. optional accessories : * nc - operated stroke (y - axis) control. * nc - operated back gauge and stroke control. * sheet support with swing - away stoppers for front gaufing. * hardened tools & special toolings. * first fill of hydraulic oil. * goose neck punch. * automatic lubrication system. * motorised back gauge with dro.

Deep Drawing Press

Get Price Quote

It is use for Making Presser Cooker, Vesseles, Oil Tank, Petrol Tank, Auto Parts, Kitchenware Products etc.

Inclinable Power Press

Get Price Quote

STEELBODY POWER PRESS FIXED, INCLINABLE & PILLER, City Presses are available in capacities of 10 tons to 250 tons geared & un geared models.frame is robust fabricated steel construction of rigid and interlock design. It is strain - free supports the ram and bed against undesired deflection under permissible loading condition.

oil hydraulic press

Get Price Quote

Cement Tiles Machine Construction : Fabricated M.S. Plates Steel Body Piston is Hard Chrome Wiper on Cylinder Top Production Capacity : 1200 Pcs per shift Mfgrs. : Cement Tiles, Chequered Tiles, Galicha Tiles, Elevation Wall Tiles Mfg. Capacity : Size of Tiles upto 375 mm x 375 mm Machine Size : 95 cm x 65 cm x 170 cm

Press Brake Machine

320,000 Per Piece

Silver Bar (Plate) Cutting Hydraulic Press Machine

Get Price Quote

This Gold / Silver / Platinum Coin Bars (Plate) Cutting Hydraulic Press Machine is a steel fabricated body hydraulically operated 60 tons press specially designed for minting Gold / Silver / Platinum Coin Bars (Plate) Cutting and medals. This is an upstroke coining press with higher ram travel speed and with extra hydraulic cylinder for return stroke to increase the production. The coin minting press is equipped with hydraulic power pack consisting of piston pump, electric control panel board operated directional control valve, relief valve, pressure gouge and standard hydraulic accessories. Automatic Option Also available. With the years of industrial experience, we have been able to serve our valued clients with an extensive range of Coins Making Machines. These machines can be availed from us in different grades and dimensions that suits best with the demands and requirements of our valued clients. We do not compromise in terms of quality and so we use high grade components for the manufacturing of these machines. Our machines can be availed form us at reasonable rates. Features: Precise designing High efficiency Reliability

Biomass Briquette Press

Get Price Quote

Drying : The material used in the briquetting plant must have moisture content less than 10%, if the moisture content is higher, you need to remove the excess moisture from the material by using the biomass material drying machine. Crushing : If the size of the raw material is larger than 200 mm, briquetting plant demands to convert into smaller pieces between 3-5mm. The biomass material crusher is used to prepare suitable size raw material for the biomass briquetting plant. The selection of the crushing machine is solely depending upon the size of the raw material. To get the support and solution concerned with crushing machine, contact us. Screening : Screening process taken under consideration after the completion of crushing process, in which the improperly sized raw material gets eliminated. The screening process is must to prevent hazardous failure of the machine and deliver the supreme quality briquettes as an end product. Briquetting : After the assurance of perfect moisture, perfect size and perfect crushing, briquetting process take place, in which biomass briquette press operates under high pressure and high temperature to compress the biomass material into small, medium or large sized bricks. The material continuously feed to the plant, once the temperature of the machine set to 300 °C. The size of the briquettes depends upon the selection of briquetting plant.

Press Brake Machine

Get Price Quote

A. P. Machine Tools is one of the leading manufacturing & supplying company of high quality press brake machine from India.

Mechanical Press Brake Machine

500,000 Per Piece

1 Piece (MOQ)

Hydraulic Press Machine

59,000 Per Piece

1 Piece (MOQ)