Pulp Molded Packaging

10 - 100 Per piece

500000 Units (MOQ)

Using raw materials that are recyclable, biodegradable or renewable can help reduce packaging waste, greenhouse gas emissions and resource consumption. Recycled materials reduce the need for extracting new resources and lower the energy consumption and greenhouse gas emissions associated with production. They also divert waste from landfills and oceans and create a circular economy for packaging materials. Renewable materials are sourced from plants that can be regrown or replenished within a short period of time, such as bamboo, hemp or wood. They reduce the dependence on fossil fuels and other non-renewable resources and have a lower carbon footprint than conventional materials, such as plastics. Both recycled and renewable materials can be recycled again after use, extending their life cycle and usability. They can also be composted or biodegraded under certain conditions, returning nutrients to the soil and minimizing environmental pollution.

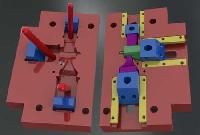

Plastic Injection Molds

50,000 - 100,000 Per piece

5000 Piece (MOQ)

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for which the process is called die-casting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed (using a helical screw), and injected into a mould cavity, Where it cools and hardens to the configuration of the cavity. After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mould-maker (or toolmaker) from metal, usually either steel or aluminium, and precision-machined to form the features of the desired part. Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. Advances in 3D printing technology, using photopolymers that do not melt during the injection moulding of some lower-temperature thermoplastics, can be used for some simple injection moulds. We can deliver the molding part as per your requirements with our best quality standards. We also provide quality testing facilities. We can assist you with design, engineering and quality standards. For which we have a molding machine. We committed to delivering high quality molding parts to our customers. We also have testing facilities for failure testing. We also provide engineering support for that.

Best Deals from Injection Moulds

Plastic Injection Molds

Get Price Quote

Plastic Injection Moulds supplied by us are of superior quality and can be easily handled and operated with higher production rate. Manufactured using superior quality raw materials, the Plastic Injection Moulds are highly durable and efficient. Applications General EngineeringMedical IndustryHouse hold applications

Injection Moulding Dies

Get Price Quote

injection mold dies

Get Price Quote

injection mold dies, Molds, Precision Components, Jigs, Plastic Dies

medical injection molding

Get Price Quote

medical injection molding, Plastic Injection Moulding

Plastic Injection Moulds

Get Price Quote

Plastic Injection Moulds, General Engineering Components, blow mouldings