Triple and Multi Roller Separator

Triple and Multi Roller Magnetic Separators for highest purify material passes through the magnet multi stage roller separator and provided at material outlet .the material flow in hopper then it’s come on vibrator. Product flow is diverted so that it falls across the surface on roller belt Ferrous matter contained in the product flow is drawn to the roll's surface (and held against it) by the powerful magnet housed inside. Here we make totally dust tight Roller Magnetic Separator available in one to eight stage roller magnetic separator in various size. Which is manufactured and assembled under strict quality control and specification to generate unsurpassed Magnetic Field Gradients. Under this High Intensity Magnetic Field, weekly Magnetic Contamination can be easily removed efficiently.

...more

Suspended Magnet

This unit simply suspended above the conveyor belt or the head pulley and lifts tramp metal from the product burden as it passes through the powerful magnetic field. Four eyebolts are provided for suspension (suspension chain not included). Cleaning is achieved by manually removing the collected tramp metal from the face of the magnet. E-Z CLEAN options are available to simplify cleaning. Available in permanent and electromagnetic designs. Suspension Type Magnets use is recommended for low contamination products.Over band type Magnetic Separator is recommended for this type of application. The capacity of suspended magnet is 20 inch coverage area The principal applications are for processing of bulk products such as Culets, Glass, Cofee, Cereals, Minerals, Coal and Sugar etc

...more

Single Drum Magnetic Separator

Single Drum Type Magnetic Separators are available for in medium and high intensity magnet. The material passes through the magnet drum type Machine respectively. These are widely used for separation of iron contamination from Minerals, Chemicals, Refractories and many other products. High power permanent Magnetic Plate is provided at material outlet. Modern An-Isotropic Permanent Magnets are used having highest magnetic strength. Machines are available with vibrating material inlet Hopper and totally enclosed design to avoid dusting and pollution.

...more

Roller Type Magnetic Separator

Roller Type Magnetic Separator are designed to remove micro iron or para-magnetic material from mineral and ceramic raw material.

...more

Rod Type Channel Magnet

Rod type channel magnets is made for slurry or grinding material, it captured ferrous contaminants from being washed off from oncoming product, a trap face design should be chosen. A trap face is a tapered step on the magnets working surface. This trap is placed at a position within the north and south magnetic fields that cause captured ferrous contaminants to be drawn to the underside of the trap where they are safely held on to, preventing was hoff from oncoming product. In rod type channel magnets usually have a 1” or 1.5” inch magnetic rods the magnetic configuration ensures maximum exposure of contamination to the high intensity rods without impeding liquid flow. Channel magnet are available in double wall jacketed. In s.s.304 and 316 steel, designs capable of working at unlimited magnetic bar are available on request.

...more

Rectangular Vibrating Screens

Rectangular vibrating screens is available in single double and multi stage screen we made for heavy industrial supply for any vibrating screener, screen design will be a key factor in unit performance and maintenance. Screen cloth that is highly pre-tensioned across a frame and securely bonded provides the best screening surface with the longest life. Cleaning kits incorporated into the screen design provide dynamic anti-blinding action when needed. Additionally, designs that enable screen changes without tools minimize maintenance costs and downtime. Vibrating screens play an important role in stone, ceramic, glass, plastic, minerals salt etc. Industries manufacturing operations. Careful analysis of all factors before ordering will result in smooth field startups and optimal production performance.

...more

Rare Earth Magnet

Earth Magnets are the most sturdy type of magnets available at present. These magnets are manufactured by us using several rare earth elements. Owing to the brittle nature of these magnets, we properly coat them with nickel to provide extra firmness. These magnets are widely used in computer hard drives, fishing reel brakes, audio speakers, bicycle dynamos, and so. We produce two primary varieties of rare earth magnets, i.e., Neodymium and Samarium-cobalt. Out of these, neodymium type rare earth magnet is comparatively cheaper. Samarium variety of rare earth magnet is a little expensive due to their complex manufacturing process and their special quality to withstand high temperatures.

...more

Pipe Line Magnetic Separator

Magnetic Liquid Filters are designed to remove micron sized ferrous and per-magnetic contamination from various types of liquids. A matrix of Easy Clean rods containing high intensity rare earth neodymium iron boron magnets are housed within a stainless steel vessel The magnetic configuration ensures maximum exposure of contamination to the high intensity rods without impeding liquid flow. Filters are available in two versions, single wall and double wall jacketed. Jacketed filters are used in heated pipeline applications where temperature is critical to the product viscosity, for example. Chocolate, syrups, jams and sauces, both these versions are tested and certified to operate at pressures up to 6 bar as standard, designs capable of working at 20 bar are available on request.

...more

Over Band Magnetic Separator

Over Band Magnetic Separators are designed to eliminate tramp metal from the product carried by belt, Used in Recycling, quarrying and heavy industries. Positioned above flat or trough type conveyors to continuously removed tramp iron and other ferrous contamination from bulk items. Large permanent magnetic packs generate deep penetrating magnetic flux fields. Rubber belt is driven around two rollers with the magnetic pack positioned in the centre. Other separators used over conveyor belts include: conveyor head rollers, strip magnets, hinged strip magnets, deep field plate magnets The Magnet is made of High Intensity Strontium Ferrite Magnets and Rare Earth magnetares guaranteed for the Magnetic Power throughout the life of installation. A Non - Magnetic Stainless steel Plate is provided to cover the poles of Magnet. There is no need for any electrical supply or maintenance.

...more

Multi Stage Drum Separators

Triple & Multi Drum Type Magnetic Separators are available for highest purity. The Permanent Drum Separators are available in standard drum diameters of 300 mm to 1200mm width range from 300 mm to 2500 mm. Other sizes can be made as special to your requirement. The larger the diameter and width of the drum the greater is the volume of material which can be hand land. These are generally manufactured as custom made where the separation is required to the highest purity of material .The material to be made free of iron particles is passed over the first magnetic drum and again in continuous process fed to the second and similarly to the third. This process ensures the purity of the material of the highest order.

...more

Magnetic Rod

Rare Earth Rod Magnets are extremely efficient at removing fine iron contamination from free flowing products such as ceramics slurry sugar, grain, tea, flour, granulate and any other types of powder with a low moisture content. This item can be supplied with blank, tapped or studded ends for ease of installation. Rods are 25.4mm (1") in diameter, 32 mm diameter, 40 mm diameter and 50 mm diameter. Rods are particularly useful for those engineers who wish to build their own separator units or have severe room restrictions and are not able to accommodate a conventional unit. This product contact parts are manufactured using 304 and 316 grade stainless steel.

...more

Magnetic Pulley

The magnetic head pulley replaces the drive pulley at the end of conveyor belts. In view of the wide variety of conveyor belt types, the magnetic pulley are supplied made to measure and ready for installation. As the figure clearly show, the magnetic head roller extracts the iron particles from the material flow and carries them to the underside of the belt where they are removed and collected. The version with permanent magnets are fitted with powerful and an-isotropic hard ferrite magnets high intensity nd - feb rare earth magnets and operate without the need for power supplies. The magnet system is available in two types: with longitudinal polar field distribution for use with low levels of iron contamination and thin material layers, and with lateral polar field distribution for greater material thickness and larger iron particles. Finally as the belt leaves the magnetic pulley, the magnetism dissipates and the unwanted contamination falls from under the belt into a separate receptacle.

...more

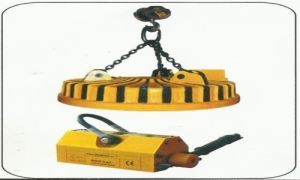

Lifter Magnet

Excel compact rare-each permanent lift magnetic, turned on and off manually by lever provide smooth operation for hundreds of lifting and positioning application. These magnetic are ideally suited for in plant handling, loading unloading of machine tools, in machines shop, plastic modules machined components, etc. No electricity needed, no batteries to or replace don’t threaten safety guarantees continuous, complete magnetic power, even after years of intensive use. Available with ‘v’ face pipes round and other hard to handle shapes. Available in 100 to 5000 kg rated lifting capacities with 33% safety factors that means magnetic are testing over 3 time the rated load circular electro lifter magnets are designed to eliminate scrap iron tramp metal from the raw material, used in recycling, quarrying and heavy industries. Offered in fabricated cases, with coils and terminals sealed and protected to ensure watertight construction and low maintenance costs. Size range from 530mm to 1525mm in diameter to suit all crane sizes and models. Magnets are designed for cool operation and minimum reduction in lift capacity, to provide maximum lift performance throughout the working day. Cases are constructed of high-permeability, low carbon steel for minimum magnetic leakage and maximum lifting efficiency. Bottom plates are heavy manganese steel. Class h insulation is used throughout the magnets for extended life.

...more

Hump Magnet

Hump Magnets generally consist of two Plate Magnets mounted in an offset housing and are installed in vertical spouts. As product enters the housing it impacts directly on the face of the first Plate Magnet, travels through the offset angle of the housing and impacts directly on the face of the second Plate Magnet Hump magnet is a unique permanent magnetic equipment to remove tramp iron pieces from gravity flow or pneumatically conveyed mixtures, the surest way to protect your costly machinery from damages. A mist for cattle feed fertilizers food processing, salt in grain handling plants. Made from high coercively permanent magnets. Very powerful magnetic plates hinged on sturdy, M. S Housing arrest all the ferrous particles from the material and prevent damage to the machinery. The plates can be easily swung open and cleaned. Ousting made of heavy M. S. A Hump Magnets are made totally dust tight enclosure and easy to clean plate of Hump, in a Hump Magnet made two or multi stage are available. This provides excellent separation results for high volume, poor flowing, or abrasive materials.

...more

Grill Magnet

Grill Magnets are important magnetic separators, used for separating tramp iron or ferrous contaminants from free flowing granular materials. Our grill magnet are made of rare earth magnets or ceramic magnets. The magnetic grills are aligned in certain angles that attracts the contaminants. Available in various shapes and sizes, our grill magnets have wide applicability in various industries like chemical industries, food processing industries, mining and mineral industries plastic and ceramic industries etc. Grill Magnets offer excellent protection from metal contamination. As product flows over the magnetic tubes, captured metal contaminants are pushed to the underside of the tube where they are now out of contact with the product flow preventing was Hoff back in to the clean material.

...more

Ferrite Magnets

ferrite magnets or ceramicsare sintered permanent magnets composed of barium or strontium carbonate, and iron oxide. this class of magnets, aside from good resistance to demagnetization, has the popular advantage of low cost. the sorts of hard ferrite magnets are manifold and complete. they are charcoal gray in color and usually appear in the forms of toroid, circular disk, square, bar, arc segment, blocks, rings, cylinders special magnets etc. the detail specifications are up to hundreds of kinds. the corrosion resistance of ferrite is considered excellent and no surface treatments are required. it can be used in temperatures up to 300 degrees c. however, ferrite magnets may have a thin film of fine magnet powder on the surface and for clean, non-contaminated applications, some form of coating may be required. magnets are available in different shapes & sizes and can also be custom fabricated according to specifications & tolerances.

...more

Double Stage Roller Separators

Double Stage Roller Separators are available for highest purity. The material passes through the magnet twice time from high intensity roller, excel magnetics made High intensity magnetic roller separator are design for very fine quality separation Which has been used successfully in Industrial Minerals applications. The Machine incorporates high energy Rare Earth Neodymium Permanent Magnetic Roller Assembly.

...more

Double Drum Magnetic Separators

Double drum type magnetic separators are available for highest purity. The material passes through the magnet twice time drum separator and high power permanent magnetic plate is provided at material outlet. They are comprised of a stationary permanent magnet, either standard ferrite magnets or high power rare earth magnets enclosed in a non-magnetic stainless-steel drum. Product flow is diverted so that it falls onto the top and flows across the surface of the drum. Ferrous matter contained in the product flow is drawn to the drum's surface by the powerful magnet housed inside.

...more

Channel Magnet

Channel Plate Magnets are important industrial separators that are meant for the separation of fine ferrous materials and large pieces of tramp iron, from many types of free-flowing and pneumatically conveyed material like corn, sugar, flour, gravel, plastic and others granular materials. It’s a one kind of plate magnet only two side border of plate magnet The channel plate magnets also goes very well with powdery, moist, lumpy, and abrasive products and large debris that might choke, bridge, or cause rapid wear in cartridge-based separators. Plate magnets are flexible enough to be deployed above conveyors or below conveyor drive pulleys to capture contaminants.

...more

Triple Stage Roller Separator

Be first to Rate

Rate ThisOpening Hours