Zero Hold Up Filter Press

Zero Hold Up Filter Press The zero hold up filter press consists of plates, perforated screens, spacers and fitter media. Interlocking spacers internally form single pipeline. The unfiltered liquid is centrally fed under pressure from bottom inlet. The liquids spreads out equally on each plate fitted with filter media. Solids remain on filter media and clear. filtrate flows through precisely made holes on sides of plates and collects in the shell, which then comes out through the outlet. In this process, solids are evenly distributed on each plate. The cake is then cleaned from the filter material and used again for filtration process. Single pass filtration with no solid bypass Full batch recovery, no separate scavenging system needed. Proper sealing which allows the filtration of volatile, toxic and inflammable products. Plate pack arrangement ensures : Any type of filtering media singularly or in combination, can be used to achieve required micron efficiency. Easy removal and cleaning of the Cartridge Assembly. Closed System ensures : Filtration of toxic, hazardous, explosive materials. Efficiently cleaned and sterilized. zero hold up filter press : No solid inside the vessel, complete recovery of liquids. Cake solids can be maximum dried with N2 Complete cake retains over the plate. Uniform filter-aid bed can be formed. Reduces the cost of expensive solvents. Contact us for Zero Hold Up Filter Presses India, Gujarat, Ahmedabad. Zero Hold Up Filter Presses consist of consists of plates, perforated screens, spacers and fitter media. Interlocking spacers internally form single pipeline.

...more

vibro sifter machines

Vibro Sifter offered by us is a vibrating energy screen, which consists of a circular pre-tensioned screen. Mounted on the frame along with the vibrating motor, the vibrating motor of these products imparts three phase vibrations to the screen due to revolving eccentric weights. Furthermore, total assembly is mounted on suitable springs and it becomes an independent body, which vibrates without parting any vibrations to the foundations. Features: High capacity & optimum use of space Process adaptability Low operating and maintenance cost Long screen life Easy for assembly & dis assembly for cleaning & change over of screens Springs amplify the vibrations leading to reduced motor HP, maintenance & operational cost Compact unit for easy of operations Available in two, three & four deck also Optional Contact parts are made out of SS316 quality material instead of SS304 Single deck/double deck/three deck Recommended Wide range of seaves available in sizes from 14/16/18/20/30/40/60/80/100/120/150/ mesh to 200 mesh Technical specifications: Model: 12’’/24’’/30’’/36’’/48’’/60’’ Drive motor: 0.25/0.5/0.5 /1.HP/1.5 HP./ 2.5 HP

...more

Vibro Sifter

We are offering vibro siftar. special features •high capacity & optimum use of space. •process adaptability. •low operating and maintenance cost. •long screen life. •easy for assembly & dis assembly for cleaning & change over of screens. •springs amplify the vibrations leading to reduced motor hp, maint. & ope. Cost. •compact unit for easy of operations. •available in two, three & four deck also. optional •contact parts are made out of ss316 quality material instead of ss304. •single deck / double deck / three deck. Recommended •wide range of seaves available in sizes from 14/16/18/20/30/40/60/80/100/120/150/ mesh to 200 mesh technical specifications. Model : 12’’ / 24’’ / 30’’ / 36’’ / 48’’ / 60’’ drive motor : 0.25 / 0.5 / 0.5 / 1.hp / 1.5 hp./ 2.5 hp screen diameter : 300 / 610 / 760 / 915 / 1015 / 1525 mm ( approx.) all contact parts are made out of ss304 quality material. ( ss316 optional ) d.o.l. Starter provided with the unit. : out put : 24’’ : up to 150 kgs./ hr. 30’’ : up to 200 kgs./ hr. 36’’ : up to 250 kgs./ hr. 48’’ : up to 400 kgs./ hr. 60’’ :up to 600 kgs./ hr. (depending upon the material properties and the screen size)

...more

Tray Dryer

We are offering tray dryer. the dryers are made of trays held in a cabinet which is connected to a source of air heated by gas, diesel or electric. The air temperature is usually controlled by a thermostat which is normally set between 50 and 550c. The air enters the bottom of the chamber below the trays and then rises, through the trays of food being dried, and exits from an opening in the top of the chamber. In the practical action systems the trays are designed to force the air to follow a longer zigzag route which increases the air / food contact time and thus improve its efficiency. operating principle of tray dryer jas enterprises offer tray dryers having capacities ranging from 12 to 200 trays and temperature ranging up to 550 celsius (932 fahrenheit) . These trays are available in the different size. A fan impeller with an axils flow design is provide for better uniformity and quick drying. Is equipped with a digital temperature indicator controller for accurate temperature control. Control action on off or pid or as required control accuracy. The material used for construction of dryer of mild steel/ aluminum/ ss 304/ ss 316 or frp-lined or as per requirements. The company offers these try dryers in flameproof and spark proof version. Heating can do through electrical /thermo fluid or steam radiator / oil fired hot air generator.

...more

Storage Vessel Tanks

We are offering storage vessel tank.We manufacture storage tanks and process equipment to the brewing, beverage, food, and waste, pharmaceutical and chemical industries. We also supply mild steel tanks. We handle the increasing demand for high quality stainless steel storage and process vessels from a wide range of industries each with its own requirements. Kush veer pharma machineries manufactures storage vessels s.s 304/316 from 50 liters to 10,000 liters which can be used for various

...more

Storage Vessel Tank

We are offering storage vessel tank. storage tanks we manufacture storage tanks and process equipment to the brewing, beverage, food, and waste, pharmaceutical and chemical industries. We also supply mild steel tanks. We handle the increasing demand for high quality stainless steel storage and process vessels from a wide range of industries each with its own requirements. Kush veer pharma machineries manufactures storage vessels s.s 304/316 from 50 liters to 10,000 liters which can be used for various applications. jacketed tanks we offer jacketed tanks that are available with following salient features: •available from 50 liter to 10000 liter •with m.s / s.s jacketed & insulation with ss cladding •direct top mounted stirrer with top dish / without top dish •different type of stirrer i.e. Propeller / pedal / anchor available. •electrical heating also available for small vessel •moc s.s 304 / 316 •bottom discharge provided •also available in liter. 100, 200, 300, 500, 1000, 1500, 2000 liter capacity. pressure vessel we hold expertise in providing pressure vessels that are manufactured using quality material stainless steel as per the latest technology. Mirrored polished from inside & outside, these vessels are also provided with ring cover wing nut and silicon gasket. Apart from this, bent outer nozzle is also fitted with stainless steel pipe in order to carry out all the fluid from the vessel. Mounted on stainless steel trolley, thee vessels are also fitted with one safety valve & two falling handles. To give smooth finish, all the welding work in these machines is done by argon arc stainless steel 316 quality. Moreover, our clients can also avail from these vessels in different capacities such as s.s 304/316 ,10 liter, 20 liter, 50 liter, 100 liter, 200 liter & above reactor vessel we manufacture reactor vessels of capacities varying from 50 liter to 10,000 liter in various materials of constructions such as stainless steels gr. 304 / gr.316 / m.s. Etc. The reactors are provided with various types of agitators such turbine, anchor, propeller or any special type as per requirement of the process. It may be provided with internal cooling coils if needed. Reactors for various industries can be manufactured, as per process need such resin plant, basic drug plant, bio reactor, open reactors etc. The s.s. Reactor can be either in mirror finish or aluminum finish as per requirement of the process / customer.

...more

Starch Paste Kettle

Sparkler Filter Press

The Sparkler Filter Press is a sparkler type and consist of S.S. Shell & Top cover using bolts to give pressure tight enclosure. The filter cartridge assembly inside the shell consists of several horizontally arranged disc type filter plates with perforated supporting screens, filter media & interlocking cups. The entire assembly complete with pump & piping connection is mounted on a suitable S.S. Trolley. STANDARD FLOW TYPE : The impure liquid to be filtered is fed to the filter shell by pump. It arrives on top of each plate through opening on the sides of plates. As liquid pressure increases, the filter media (Paper.fabric) holds back the impurities & allows the crystal clear filtrate to pass through the central channel (formed by interlocking cups) which takes the filtrate to the outlet of filter. This filter most commonly used to obtain clear liquid. However if required, the cake formed between the plates can be obtained. Filtration is continued until its rate becomes very slow due to increased cake resistance. • Manufactured in S.S. 304 / S.S. 316 / S.S. 316L M.O.C• M.S / S.S. Jacket can be provided for hot filtration .• Gives crystal clear filtration by filtering particles up to 1 micron size.• Scavenger arrangement to remove all the liquid.• Cake can be dried either by compressed air or by insert gas, steam.• Filtration rates from 600 Ltrs/hr. to 30000 Ltrs/hr possible depending on the models.• Centrifugal / Gear / Lobe pumps can be offered, which can also be used for liquid transfer.• Sample collecting device & safety valve provided.

...more

S.S Storage Tanks

By offering an excellent quality range of SS Storage Tanks to our clients, we have managed to win their appreciation. SS Storage Tanks supplied by us in this range are made from very high quality stainless steel as the raw material, which helps us ensure their durability to the end user. These ss storage tanks can be availed by our esteemed clients in various patterns and designs. Features: Light in weight Corrosion resistant Dimensionally accurate

...more

Ribbon Blender

We are offering ribbon blender. ribbon blender comprises of a u-shaped horizontal trough and a specially designed double helical ribbon agitator rotating within. Ribbon blenders are based on a proven agitator construction that provides a triple mixing action ensuring fast, efficient blending. The dimensions and configuration of the ribbons are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge. an alternate design is the paddle agitator. The paddles are positioned to move the material in opposing lateral directions as well as radially. The paddle design is generally employed where friable materials are being blended, and when batches as small as 15% of the total capacity are going to be mixed in the blender. design highlights •the outer ribbon displaces the material from the ends to the center while the inner ribbon moves the material from the center to the ends. This counter-current action results in homogenous blending. •the ribbons rotate at approximately 70 - 100 meters per minute and move the material both radially and laterally to ensure thorough blends in short cycle times. triple mixing action - the key to fast, efficient blending •as the agitator rotates, the material is tumbled and carried radially around the inside of the blender. •the pitch of the outer ribbon moves the material toward the discharge opening. •the inner ribbon which has an opposing pitch moves the material away from the discharge opening. Litres. 10/50/75/150/250/450/600/1100/1500/. Litres.

...more

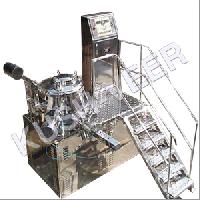

Rapid Mixer Granulator

We are offering storage vessel tank. Rapid mixer granulator high shear mixer granulator operation rapid mixer granulatoris designed to achieve excellent mixing and consistent granules at lower operating cost along with higher productivity. Better mixing and closed control of granule size leads to faster tableting speeds with improved quality and least rejections. Special features model available from 60 liters to 1250 liters capacity gross capacity. The gross capacity & working capacity in liters and working capacity in kgs. Are mentioned on next page. Rmg - with right side discharge valve

...more

Powder Mixing Machine

powder mixing machineWe are engaged in providing our customers with whose models are made available in 25 to 3000 ltr and in bigger sizes as well. Operation The octagonal blender is an efficient and versatile blending machine used for mixing and lubrication process of dry granules homogeneously. Two third of the volume of the Cone Blender is filled to ensure proper mixing. The Octagonal Blender gives best results for granules due to very slow speed and octagonal shape of container. It can be used for manufacturing pharmaceutical, food, chemical and cosmetic products. In Octagonal Blender the granules come from all sides due to the octagonal shape of the product container, hence requirement of RPM is less. Suitable mainly for crystalline & granular type material. This type of material gets sufficient continuous movement due to their shape. If container has only slow movement, this will result in good quality blending and lubrication of granules. Features: Suitable for dry mixing of products in granule form Easy for loading and unloading of material Easy for cleaning All contact parts are made out of SS 304/SS 316 or SS 316 L quality material, as per customer requirement The octagonal shape & slow speed of rotating gives sufficient continuous movement to the granules, result in good quality Simple design requires minimum maintenance General structure & safety guards made out of mild steel & coloured in Standard Model and made out of SS 304 & polished to the matt finish in GMP Model Maximum care has been taken to ensure safe operation of the unit Manual rotating facility with hand wheel for inching Bigger size batch at low power consumption Optional - (will be provided on extra cost on your demand) Contact parts made out of SS316 instead of SS304 Flame proof drive motor along with flame proof starter Vacuum Loading facility for material charging Cylindrical container with cone for material charging 25 to 3000 ltr & bigger size.

...more

Mechanical Sifters

Mechanical Sifter offered by us is a vibrating energy screen, which consists of a circular pre-tensioned screen. Mounted on the frame along with the vibrating motor, the vibrating motor of these products imparts three phase vibrations to the screen due to revolving eccentric weights. Furthermore, total assembly is mounted on suitable springs and it becomes an independent body, which vibrates without parting any vibrations to the foundations. Features: High capacity & optimum use of space Process adaptability Low operating and maintenance cost Long screen life Easy for assembly & dis assembly for cleaning & change over of screens Springs amplify the vibrations leading to reduced motor HP, maintenance & operational cost Compact unit for easy of operations Available in two, three & four deck also Optional Contact parts are made out of SS316 quality material instead of SS304 Single deck/double deck/three deck Recommended Wide range of seaves available in sizes from 14/16/18/20/30/40/60/80/100/120/150/ mesh to 200 mesh Technical specifications: Model: 12’’/24’’/30’’/36’’/48’’/60’’ Drive motor: 0.25/0.5/0.5 /1.HP/1.5 HP./ 2.5 HP

...more

mass mixers

Mass Mixers offered by our organization are utilized for processing products such as tablets and powder, among others. The Mass Mixer machine is basically a mixing assembly wherein the mixing stirrer is in a horizontal position in the container and have a single speed, simple rotation. The stirrer rotates around it self at a very slow speed inside the bowl and thereby achieves intimate mixing of dry or wet material of tablet granulation, powder, chemicals and food & confectioneries. Owing to the special design of the machine and stirrer, the mass mixer can easily mix the sticky material. These machines can also uniformly and intimately mix material, which are too difficult to mix. Features: Range of models to suit working volume: 5/50/100/200/500 Kgs at bulk density of 0.50 gms/cc All contact parts are made out of S.S.304 quality material (SS316 provided on demand on extra cost) Compact design requires comparatively smaller floor space Single stirrer with single speed for dry & wet mixing As stirrer's sealing comes in contact with product, there may be any black particle contamination problem, after sealing bush gets wear & tear All non contact parts (general structure) are made out of mild steel and claded with SS304 or chrome plated or made out of SS304 in GMP Model. Contact parts are polished to the mirror finished and non contact parts are polished to the matt finished in GMP Model. All safety guards & covers made out of SS304 material in GMP model & made out of mild steel & painted in standard model General structure & all non contact parts are made out of Mild Steel & same will painted in standard model All moving parts are enclosed with safety guards Thrust bearings are provided to carry out rigid thrust load Easy cleaning and operating Simply designed SS304 dust cover provided with one port for material charging & inspection Interlocking system with top dust cover, to avoid accident, during process The container tilting system provided for easy unloading of material and easy cleaning Specially design all moving parts provided with provision of easy lubrication Optional: SS316 product contact parts instead of SS304 Variable speed drive or double speed of stirrer provided on extra cost, if required Flame-proof model

...more

Mass Mixer

We are offering Mass Mixer. Mass Mixer for Tablet / Powder TheMass MixerMachine is basically mixing a assembly wherein the mixing stirrer is in horizontal position in the container & have a single speed, simple rotation. The stirrer rotates around it self at a very slow speed inside the bowl and thereby achieving intimate mixing of dry or wet materials of Tablet Granulation, Powder, Chemicals, Food & Confectionaries Materials. Because of a special design feature of machine & stirrer, the mass mixer can be mix the sticky materials & also uniformally and intimately mix the materials which are to be difficult to mix. Special Features •Range of models to suit working volume.Kg. 5/50/100 /200 /500.Kgs. At bulk density of 0.50 gms/cc. •All contact parts are made out of S.S.304 quality material. (SS316 provided on demand on extra cost) •Compact design requires comparatively smaller floor space. •Single stirrer with single speed for dry & wet mixing. •As stirrer's sealings comes in contact with product, there may be any black particle contamination problem, after sealing bush got wear & tear. •All non contact parts (general structure)made out of mild steel and claded with SS304 or crome plated or made out of SS304 in GMP Model. Contact parts are polished to the mirror finished and non contact parts are polished to the matt finished in GMP Model. All safety guards & covers made out of SS304 material in GMP model & made out of mild steel & painted in standard model. •General structure & all non contact parts are made out of Mild Steel & same will painted in Standard Model. •All moving parts are enclosed with safety guards. •Thrust bearings are provided to carry out rigid thrust load. •Easy for cleaning & operating. •Simply designed SS304 dust cover provided with one port for material charging & inspection. •Interlocking system with top dust cover, to avoid accident, during process. •The container tilting system provided for easy unloading of material and easy cleaning. •Specially design all moving parts provided with provision of easy lubrication. Optional •SS316 product contact parts instead of SS304. •Variable speed drive or double speed of stirrer provided on extra cost , if required. •Flameproof model.

...more

laboratory mixers

Laboratory Mixers the versatile Laboratory Mixers s designed to mold miniature specimens for dynamic, tensile and impact testing. This benchtop mixer, extruder and molding machine will produce cost effective moldings using less than one gram of material

...more

Jacketed Tanks

Clients are also provided with optimum quality Jacketed Tanks that can also be availed by them in customized sizes and specifications. These tanks are specially designed to the cater to the requirements of various industries. Known for their international standards, these jacketed tanks find widespread utilization in various industrial applications. Some of the other details of our products are as follows: Available in the range of 50 litre to 10000 litre capacities M.S./S.S jacketed & insulation with SS cladding Direct top mounted stirrer with top dish/without top dish Different type of stirrer i.e. propeller/pedal/anchor available Electrical heating also available for small vessel MOC S.S 304/316 Bottom discharge provided Also available in 100, 200, 300, 500, 1000, 1500, 2000 litre capacity

...more

Industrial Shifters

Industrial Shifters Vibro Sifter Machine offered by us is a vibrating energy screen, which consists of a circular pre-tensioned screen. Mounted on the frame along with the vibrating motor, the vibrating motor of these products imparts three phase vibrations to the screen due to revolving eccentric weights. Furthermore, total assembly is mounted on suitable springs and it becomes an independent body, which vibrates without parting any vibrations to the foundations. Features: High capacity & optimum use of space Process adaptability Low operating and maintenance cost Long screen life Easy for assembly & dis assembly for cleaning & change over of screens Springs amplify the vibrations leading to reduced motor HP, maintenance & operational cost Compact unit for easy of operations Available in two, three & four deck also Optional Contact parts are made out of SS316 quality material instead of SS304 Single deck/double deck/three deck Recommended Wide range of seaves available in sizes from 14/16/18/20/30/40/60/80/100/120/150/ mesh to 200 mesh Technical specifications: Model: 12’’/24’’/30’’/36’’/48’’/60’’ Drive motor: 0.25/0.5/0.5 /1.HP/1.5 HP./ 2.5 HP

...more

Hexamide Storage Tanks

Our organization is known in the industry for providing our clients with an excellent quality range of Hexamide Storage Tanks. In order to ensure quality of our storage tanks, we make use of high grade quality raw material and latest machinery in the production process. Further, these tanks can also be manufactured in customized designs, as per our client's specifications. Widely known for durability and quality Corrosion resistant Dimensionally accurate.

...more

Fluidized Powder Dryer

GMP Fluid Bed Dryer with latest improved design makes this unit a truly versatile for Pharmaceutical, Food, Dyestuff & Chemical industries. Our Fluid Bed Dryer is capable of drying materials in any forms like granular, powder or crystalline. Afluidized bed of solid particles with a stream of air passing up-ward through the particles at a rate great enough to set them in motion. As the air travels through the particle bed, the particles behave as boiled water. The active motion creates the potential for improved mixing and results an isothermal property. In a bubbling fluidized bed, no temperature gradient exists within the mass of the fluidized particles. Because the temperature and volume of the air can be precisely adjusted, the process achieves fast heat transfer making it very efficient, yet gentle on the product. Our product precisely maintains moisture content up to 20% which is ideal for pharmaceuticals and chemicals .

...more

Fluid Bed Dryers

Fluid Bed Dryer The capacity ranging from 10 / 30 / 60 / 120 / 150 / 200 / 250 / 300 / 500 Kgs., with steam heating / electrical heating & thermal heating facility. Electrically / Steam & Thermic Fluid Heated in which general structure, made out of mild steel & painted in Standard Model & made out of S.S.304 quality material & polished to the matt finished in GMP Model, but contact parts i.e. Product Container and Retarding Chamber, are made out of S.S.304 / S.S. 316 quality material, with Non-Flameproof blower motor, (Flameproof motor provided on demand) suitable to dry wet material. Three Piece GMP Mode Operation FLUID BED DRYER is designed to introduce the hot air stream at the base of the product container which is filled with the material. Induced draught is created by means of blower and fresh air is sucked in to the unit. The fresh air is heat by means of electrical heaters or steam or thermic fluid heaters. This hot air stream expands the bed of material at certain velocity & creating turbulance in the product. The phenomenon is known as fluidisation and offer conditions which are almost ideal for drying. Fluidisation produces full agitation of solid particles and since each particle gets surrounded by hot air, heat transfer is extremely high and uniform. The product is dried fast without appreciable loss of heat. Filter bags prevent particles escaping from the dryer. Suitability The conventional drying method of drying products in tray dryer is rather inadequate and trouble some. They occupy large floor space, have very high drying times, are labour intensive and offer uneven drying. On contrast Fluid Bed Dryer occupy comparatively lesser floor space, are very easy to operate & can dry material in least time as compared to tray dryer. In Fluid Bed Dryer, temperature distribution through out the product is uniform and the heat transfer rate is very high. Due to the reduce drying time high production rates are achieved. As the product is in close contact with drying air at low temperature and also for short duration, the physical and chemical properties of the products are generally not effected and therefore the dryer can effectively be used for heat sensitive products. Due to the continuous movements of product during drying lump formation, case hardening etc. are minimized. The Fluid Bed Dryer are most suitable for drying granular, crystalline, coarse or similar material in pharmaceuticals, fine chemicals, dyes, food and allied products. The Fluid Bed Dryer is not suitable for drying liquids or pasty materials. Special Features •Uniformity in drying and reduction in drying time. •Atmospheric inlet air is filtered by means of non woowen filter cloth. PRE /MICRO V & HEPA filters can be provided on demand on extra cost to prevent any fine dust to pass through the products. •Digital temperature indicator cum controller for inlet air & Digital temperature indicator for outlet air, are provided for electrically heated model. •Digital temperature indicator are provided for inlet & outlet air, in steam / thermic fluid heated model. (Temperature controlling valves will be in customer scope of supply) •Manually operated air dampers provided to control the inlet and outlet air flow. •An explosion safety flap of adequate capacity at the rear of dryer and an earthing point to prevent static charge in the machine. •Contact parts RETARDING CHAMBER & PRODUCT CONTAINER are made out of SS304 & polished to the mirror finished and other parts are made out of SS 304 and polished to the matt finished in Gmp model & made out of •M.S. & Painted in standard model.

...more

cone mixers

Salient Features of S.S Double Cone Blender: The conical shape at both ends of Double Cone Blender enables uniform mixing and easy discharge. All contact parts are made out of stainless 304 or 316 quality material, as required by customer. Maximum care has been taken to ensure safe operation of Double Cone Blender. Manual rotating facility with hand wheel for inching. The same will be provided with ss cover & limit switch. (In 200 Kgs. & above model) Two nos. of safety road will be provided at back side. ( One LH side & one RH side ) Suitable size of butter fly valve at one end of the cone provided for material discharge & hole with openable cover provided at other end of the cone for material charging & cleaning. One shaft with 04 nos. of fixed buffels with mirror polished provided inside the cone. Cones of the Double Cone Blender will be mirror polished from the inside & outside & structure will be matt polished. All moving parts of the Double Cone Blender are covered with SS304 covers. Safety guards made from SS304 pipes provided in front of the m/c with limit switch. Panel fabricated from SS304 material with facility of three phase indication, D.O.L. tarter, digital timer & Amp. Meter. As per customer requirement machine will be provided with left side drive or with right side drive. The conical shape at both ends enables uniform mixing and easy discharge. All contact parts of the Double Cone Blender are made out of SS304/316

...more

cone blenders

We are reputed as one of the leading manufacturers, suppliers, importers, distributors, retailers, traders and service providers of excellent quality Cone Blender. Our cone blenders are made from excellent quality stainless steel with very strong and durable frames. These cone blenders are efficient for mixing different kinds of substances in very consistently manner. Our cone blenders are fitted with easy to use control panel which can be programmed for desired speed and time for blending the materials. Features: Provide efficient and consistent blend User friendly Sturdy construction Easy discharge of the product

...more

Chemical Storage Tanks

We have generated a positive response in the market by providing excellent quality Chemical Storage Tanks to our clients. Manufactured using high grade material, these Chemical Storage Tanks are widely appreciated by clients located across the nation. Offered at most reasonable pricing, these tanks are high in demand and are utilised in various applications. Offered in various sizes and specifications Easy to install Long functional life

...moreBe first to Rate

Rate ThisOpening Hours