Wet Drum Magnetic Separator

Magnetic Separators are available for in medium and high intensity magnet. The material passes through the magnet drum type Machine respectively. These are widely used for separation of iron contamination from Minerals, Chemicals, Refractories and many other products. High power permanent Magnetic Plate is provided at material outlet.

...more

Wet Drum Magnetic Separation

The wet drum magnetic separator (known as NTS) is used to remove very fine magnetisable components from low concentration, low-viscosity liquids. NTS is mainly used by metal processing industry and for the treatment of pre-concentrates extracted from high gradient magnetic filter. About 90% of the very fine magnetisable components can be separated as sludge. Features such as stainless steel housing and powerful neodymium iron boron magnets are standard. General Principles: The liquid flows through a semi-circular separating chamber beneath a stainless steel drum to which the magnetisable particles are attracted. The strong, high-gradient magnetic field is created by a cylinder consisting of permanent magnetic discs positioned within the drum. These special permanent magnets generate particularly high field gradients which are necessary for successful separation, as is the need with all Magnetic-Separators. For recovering Magnetic/Ferro-silicon in dense media plants and iron ores, wet drum separators are mainly used. They remove contamination from the product stream, increasing product purity and plant productivity. In the applications where the product purity is most essential, the wet drum separators can use powerful Rare Earth Magnets, which can remove very fine and weak contaminants even from dense materials. Features of Wet Drum Magnetic Separator: Wet drum magnets have high magnetic recovery and discharge. The feed slurries recover the magnetic. It is available in single or multiple drum applications. Recover magnetic solids in as clean as a magnetic concentrate. Permanent magnet assembly eliminates coil burn-outs The magnet/pole elements are bolted to a mild steel shaft. The drum is made from thick stainless steel for long service life. Wet drum separators are available in different configuration like single drum, double drum and multiple drum. In double drum two separators are arranged back to back with a common feed back.

...more

Vibro Sifter

Vibro Sifter is a circulatory screening machine, used for screening of solids or liquids in diverse industries. It not only grades material as per particle size, but also used for the separation of mass composition of solid and liquid. Vibro Sifter consists of specially designed motor, mounted vertically at the center of the base plate of the screen. The screen is placed between the feeding hopper and the container. The particle is fed through the screen, where the smaller particles of uniform sizes pass to periphery while oversized particles are discharged. Vibro Sifters are designed for uniform and fast separation while consuming less power. We also customize Vibro Sifters as per the client’s specification. Vibro separators are circular unitary gyratory screens used to separate mass composition of solids from solids, liquid from solid and for gradation of materials as per particle size, having a very wide range application. This is accomplished by vibrating the screens in three different planes along the vertical axis by means of a specially designed vibratory motor having off centered weights at the top and bottom end of the motor shaft. The top weight causes vibration in the horizontal plane which causes the material to move across the screen towards the periphery. The lower weight acts to tilt the machinery which causes vibration in the vertical tangential axis. The angle of lead of the lower weight with relation to the upper weight provides variable control of the screening pattern. Thus the material moves across the screens and also in the vertical and tangential planes enabling maximum screening. “GEBERIX” Vibro sifter are available with a wide range of possible screen sizes (mesh) Option for multiple deck separation is also possible.

...more

Vibro Sifter

Vibro Sifter is a circulatory screening machine, used for screening of solids or liquids in diverse industries. It not only grades material as per particle size, but also used for the separation of mass composition of solid and liquid.

...more

vibro motor

Vibratory Motor used as drive – unit for vibrating machines for application such as Bin-Discharging, bulk – product conveying (horizontal or vertical) Sizing or coarse, Screening, Vibrating feeders, Paper jogger, Vibrating Tables, Vibrating Conveyors, Concrete Hoppers, Vibrating Grizzly Feeders, Dewatering, Compaction, Discharge – aid in bins and silos. Different type of material can be handled by Vibratory Motor such as Sugar, Starch, Salt Sand Tobacco, Coal, Cement, Detergent, Flour, Garbage, Chemicals, Powders, Plastic, Concrete.

...more

Vibro Bowl

Our company is a market forerunner in manufacturing Vibro Bowl with the advent of modern technologies. Vibratory bowl Feeders are very flexible and capable of feeding a wide variety of parts that finds application in electrical components, glass vials, feeding molded plastic parts, stamped formed or machined parts. Vibro Bowl Feeder offered by us is highly expedient in production industries such as automobile, pharmaceutical, lamp caps, bottle caps, electronics and electrical. Our product ensures maximum efficiency and low maintenance as they hold various advanced features Features of Vibro Bowl : High Tensile Strength Saves energy Easy installation Optimal power consumption

...more

Vibratory Table

Our company is tagged as a reliable manufacturer of Vibratory Table that is perfect to handle a variety of products from cold to hot, dry to damp and fine to coarse in small and bulk quantities. The offered quality product is equipped with quality raw material for application several industries like automobile, electronic, chemical and pharmaceutical industries. Our Vibratory Conveyor Table is available with amplitude of 2mm and 2 Tons load capacity. We have acknowledged ourselves as a best Vibratory Table Manufacturers in India. Features It occupies less floor area. High load capacity Long functional life Adjustable frequency Minimal maintenance

...more

Vibratory Feeder

Vibratory feeder are ideally suited for controlling the flow of bulk materials to secondary processing operation. Vibrations produced are smooth, uniform, volumetric flow that is fully variable from a dribble to surge. Vibratory feeders are used to control product flow in bulk handling operation such as packaging, batching, mixing, drying, weighing, sprinkling and spreading. Our feeders have handled a variety of materials, from dry to damp, cold to hot, fine to course, with different bulk densities. Some of the applications include; use in chemical plant – to control flow of ingredients to mixing tanks, the Food Industries to sprinkle nuts and topping on cakes and ice-cream products. Linux Magnetics offers a full range of vibratory feeder to convey, screen and feed materials in quantities ranging from a tiny to tons per hour. We develop custom-designed vibratory and screening equipment to precisely meet your requirement. Many might think as to how a small machine can help transfer heavy loads across two surfaces. Machines are used to ease the human efforts and there are a variety of machines available in the market that can decrease human efforts. Now, which machines to use and how they work, depend on the requirement of the people. There are a variety of machines that are used to transfer goods from one place to another. Talking of machines that transfer goods from one surface to another, one of the most widely used machine in the world is the vibratory feeder. Speaking of Vibratory Feeders, many may wonder what the instrument is and how it helps in transferring of loads in between two surfaces. The answer is simple the instrument consists of a vibrating screen that is connected to an electric motor. Now, as soon as the electric motor will get a current, the motor will transfer a signal onto the screen and the screen will start vibrating. These vibrations that are created will set the particles that are present on the screen to vibrate and to move further. As soon as the particles move further we will collect them on the other side of the feeder. The working though seems simple to understand but the instrument takes highly complex physical principles to work. So, forgetting about the complex physical principles involved in the working of this vibratory feeder, let us change our path of thinking towards finding important suppliers that supply this modern invention. One of the well-known suppliers that have been known for their quality products and machines in the market are the Linux Magnetics. The company has a wide range of products and machineries at your service and this along with 5 years of experience in providing the highest quality of machineries that have proved to be a marvel in any company that it is sold to. All the products that are manufactured by the company are made under the highest surveillance with just one mindset and i.e. to provide the best quality to the customers so as to create a feeling of mutual respect among the company and its customers. Again for people confused about the usefulness of the vibratory feeder in their business, there is no fixed guideline about the load that the machine can transfer. No matter if you have to transfer heavy loads or lighter packages, these feeders can be of use to you in all the cases. You have a number of these feeders so that you get the best one of your choice. There are special feeders that are manufactured to carry and transfer heavy loads that have an electric motor with very high power and a large vibrating screen that have specially been designed to transfer such heavy loads. These loads can be simple rock pieces or heavy storage piles. All these and many more can be easily transferred between two junctions with the help of these feeders. The feeders are highly useful for customers who need machines that can transfer loads between short areas such as from their factory to a nearby work area and such. Vibratory Feeder Types Electro Magnetic Type Twin Unbalance Motorized Type UF – Exciter Driven Type. Eccentric Drive Type.

...more

Vibrator Motor

Excel Magnetic's Vibrator Motor are well equipped with special profile bearings with high carrying load and increased bearing work. It results into long bearing life. The vibrator motor is another kind of electric object that obtains quality separation with the centrifugal force unlike the screens. The shafts and eccentric blocks are used for fast rotation of the motors along with the substance in them and the two layers of the separated products are obtained. Using the motors Quiet easy to handle and repair are they. These motors are installed in the environment that has enough space for them to fix. They are used in majority of the hydropower constructions, thermal power generation plants and even the metallurgy and light industries. Factors to bear Check your vibrator motor well when you get it delivered at your industry. See to it that the bolts and tails are flexibly fit or not. Fasten the moving wrenches of the motors. The vibration speed or level is normal or not, do check with accordance to your need. Hygiene is the foremost check that you require to make. The vibrator motors and the screens are some of the essential parts used for the separation, basically and only then can a pure material be attained as the product after the various steps of productions. Features of Vibrator Motor Durable Reliable High Performance Value for money

...more

Vibrator Motor

Linux Magnetics was incepted in the year 2008 and manages all its operations from Ahmadabad, Gujarat. Excel Magnetic's Vibrator Motor are well equipped with special profile bearings with high carrying load and increased bearing work. It results into long bearing life. Features: Durable Reliable High Performance Value for money.

...more

Vibration motor

Our Unbalance Vibratory Motor used as drive – unit for vibrating machines for application such as Bin-Discharging, bulk – product conveying (horizontal or vertical) Sizing or coarse, Screening, Vibrating feeders, Paper jogger, Vibrating Tables, Vibrating Conveyors, Concrete Hoppers, Vibrating Grizzly Feeders, Dewatering, Compaction, Discharge – aid in bins and silos. Different type of material can be handled by Vibratory Motor such as Sugar, Starch, Salt Sand Tobacco, Coal, Cement, Detergent, Flour, Garbage, Chemicals, Powders, Plastic, Concrete.

...more

Vibrating Screening Machine

We are one of the leading manufacturer and exporterof Vibratory Screening Machine in India. We offer good quality Industrial Vibratory Screening Machine that has found applications in large number of industries. The Vibrating Screen is manufactured from high quality raw materials and its best known for its features like high performance and strength. Moreover, we provide availability of Vibratory Screen in varying materials and mesh size as per the preferences of customers. We also ensure safe and prompt delivery of Vibrating Screen to the destination set by customers. Uses of a Vibrating Screen with an understanding of Vibrator Motor A 2YKH-2245 is a heavy vibrator motor screen designed and manufactured by the Henan Hongxing Mining Machinery. It is first used in an open pit coal preparing plant in the year 1983 to substitute the spiral screen for the sculpting gangue with grading large and medium masses, which has carried out innovations and practices for the heavy vibrating screening goods. Numerous large tools of the Henan Hongxing Mining Machinery are brought in from foreign countries. A super heavy screening device is required to match for devices that are imported. The Henan Hongxing Mining Machinery effectively developed YAC-2460 super heavy screen in 1992, whose utmost feeding size might be up to about 400mm with the capacityof 1000t/h. Better results have been received following it the start of its use. While a vibrator motor runs with the effect of vibrator, screen cloth and screen box will shift onto oval, circular, or linear movement that will make the material on surface of the screen scatter and lift up and down. Therefore, fine particles may fall through the material deposit and after that expel from a sieve hole. Also the larger particles will keep on moving forward with effect of

...more

Vibrating Screen

We offer supreme quality Vibrating Screen that is used in varied applications and is on a huge demand in the national as well as international market. The Vibrating Screen that we bring forth is manufactured with great precision in order to meet the varied needs of the customers. Features Screens free flowing materialsEnsures material travelling at a constant rateAdjustable amplitude of vibration degreeConsumes lesser time Specifications Fixed angle or adjustable bracked arrangementScreen's inclination-15 Deg. to 20 Deg.Speed -800 R.P.M to 1200 R.P.M Lengths -from 1200 mm to 600 mm Widths in m.m600800100012001400160018002000 m.m Number of decks –up to four

...more

Vibrating Grizzly Feeder

There are various models of our vibratory equipment to choose from and the Grizzly feeder has been extensively used in the construction and building industry. Our machines have been relied on for its reliability and the volume that it can go through in a working day. Vibrating equipment is available in many models with us and the Grizzly feeder is a specific machine used to sort through heavy products before they can move on to the next stage like a crushing machine.

...more

Vibrating Feeders

Provided by us are Vibrating Feeders that are ideal for handling different materials like hot, lumpy, damp, dusty, etc. The Vibrating Feeders that we deal in is suitable for conveying bulk material between processes and that too at continuous & controlled rate of flow. Also, the Vibrating Feeders are known for their compliance with the international quality standards like IS: 8723-1978. Features Electromagnetically poweredHigh frequency reciprocating machine Tray on drive unitsTwo sets of leaf springs Solid cast iron base and armature Ensures smooth, free, uniform and volumetric flowSingle, dual and multiple magnet drives Functions Flow of material from storageMixingWeighingProportioning and blendingPackagingprinkling CrushingWashingScreeningScalingDustingSpreadingDryingHeatingCoolingBatching Specifications 3000 vibrations per minute at 50HzStiffened with anglesHalf-wave rectifierControl panel for varied amplitude of vibrations and external feed rateWear resistance plate Class H insulation Powerful electromagnetic coils (double fibre glass, copper wire)Withstand adverse atmospheric conditions Applications TransportationAbrasiveFastenersFertilizerCeramicChemicalFood PharmaceuticalPlasticFoundryMines & MineralsPulp & Paper

...more

Unbalance Vibro Motor

Our Unbalance Vibratory Motor used as drive – unit for vibrating machines for application such as Bin-Discharging, bulk – product conveying (horizontal or vertical) Sizing or coarse, Screening, Vibrating feeders, Paper jogger, Vibrating Tables, Vibrating Conveyors, Concrete Hoppers, Vibrating Grizzly Feeders, Dewatering, Compaction, Discharge – aid in bins and silos. Different type of material can be handled by Vibratory Motor such as Sugar, Starch, Salt Sand Tobacco, Coal, Cement, Detergent, Flour, Garbage, Chemicals, Powders, Plastic, Concrete

...more

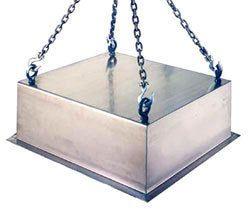

Suspension Magnets

Our range of magnetic equipment is among the best that is available in the industry. We have a range to suit all kinds of industry requirements and products. The suspended magnet is the most popular for its simplicity in design and its high success rate in eliminating ferrous substances from the feeders or belts. Everything from pieces of iron to ferrous particlesisneatly removed as they pass under the suspended magnet. This not only helps to increase productivity but by using a suspended magnet an assurance of a well sorted product is ensured.

...more

Suspension Magnet

We Bring Forth in the Markets Suspension Magnets that are Extensively Used for Products with Low Contamination to Be Carried Through Belt Conveyors. Suspension Magnets are Made in Accordance with Set Industrial Standards and Norms. to Suit the Precise Requirements of the Customers, We Offer These Suspension Magnets At Market Leading Prices and in Safe Packaging. features high Grade Compact Design, Anti-abrasive, Long Functional Life, Light in Weight. used for Processing Of: glass Sugar, Coal, Cereals, Culets, Minerals, Coffee.

...more

suspended magnets

The ferrous metal that is separated from the conveyor belts or from sloping chutes has many uses. These pieces or bits of Iron are also recycled and reused in various other processes. If you have a production unit that needs the items on the feeder to be cleaned and free of any kind of contaminating metal, particularly ferrous metal then we have the solution for you. Our range of magnetic equipment is among the best that is available in the industry. We have a range to suit all kinds of industry requirements and products. The suspended magnet is the most popular for its simplicity in design and its high success rate in eliminating ferrous substances from the feeders or belts.

Feature : obust industrial design. Manufactured to customer specification.

...more

Single Drum Magnetic Separator

Single Drum Type Magnetic Separators are available for in medium and high intensity magnet. The material passes through the magnet drum type Machine respectively. These are widely used for separation of iron contamination from Minerals, Chemicals, Refractories and many other products. High power permanent Magnetic Plate is provided at material outlet. Modern An-Isotropic Permanent Magnets are used having highest magnetic strength. Machines are available with vibrating material inlet Hopper and totally enclosed design to avoid dusting and pollution

...more

Roller Magnetic Separators

Roller Type Magnetic Separator are designed to remove micro iron or para-magnetic material from mineral and ceramic raw material,. Double Roller Separator Double Stage Roller Separators are available for highest purity. The material passes through the magnet twice time from high intensity roller, Linux Magnetics made High intensity magnetic roller separator are design for very fine quality separation Which has been used successfully in Industrial Minerals applications. The Machine incorporates high energy Rare Earth Neodymium Permanent Magnetic Roller Assembly, Triple and Multi Roller Separator Triple and Multi Roller Magnetic Separators for highest purify material passes through the magnet multi stage roller separator and provided at material outlet .the material flow in hopper then its come on vibrator. Product flow is diverted so that it falls across the surface on roller belt Ferrous matter contained in the product flow is drawn to the roll's surface (and held against it) by the powerful magnet housed inside. Here we make totally dust tight Roller Magnetic Separator available in one to eight stage roller magnetic separator in various size. Which is manufactured and assembled under strict quality control and specification to Generate unsurpassed Magnetic Field Gradients. Under this High Intensity Magnetic Field, weekly Magnetic Contamination can be easily removed efficiently.

...more

Roller Magnetic Separator

The Roller Magnetic Separator offered by us is tested using various testing facilities. The Roller Magnetic Separator is appreciated for high gradient, high intensity, indigenous technology permanent magnetic roller separators, high energy rare earth neodymium permanent magnetic roll assembly, easy removal of contaminants, generation of unsurpassed magnetic field gradients. Availability Dia.-65, 75 & 100mm Magnetic Strengths8,000 Gauss20,000 Gauss22,000 GaussWidths up to 1200mm0.5 HP-variable speed Adjustable from 0 to 100 RPM DC/AC Geared Motor drive Abrasion resistant conveyor Beltsthickness -0.8mm Vibratory Feeder Applications MagnesiteSilicaCarbideRefractory CeramicQuartziteFeldsparDolomiteGraphite UpgradingAbrasiveAlumina Diamond ore benificationRemoving Ferro Silicates from Magnesite, Limestone, etc.Mangense ore benificationBauxite UpgradingSeparating Garnet, Rutile, Ilmenite, Zircon, Iron ore Benification Recovering Metals from Slag

...more

Rectangular Vibrating Screens

Rectangular Vibrating Screens is available in single double and multi stage screen we made for heahy industrial supply For any vibrating screener, screen design will be a key factor in unit performance and maintenance. Screen cloth that is highly pre-tensioned across a frame and securely bonded provides the best screening surface with the longest life. Cleaning kits incorporated into the screen design provide dynamic anti-blinding action when needed. Additionally, designs that enable screen changes without tools minimize maintenance costs and downtime. Vibrating screens play an important role in stone ,ceramic , glass, plastic, minerals salt etc. industries manufacturing operations. Careful analysis of all factors before ordering will result in smooth field startups and optimal production performance.

...more

rare earth rod

Be first to Rate

Rate ThisOpening Hours