Liquid Juvederm Volift Fillers

15,000 - 18,000 Per Box

1 B (MOQ)

Liquid Fillers

Get Price Quote

We are the main supplier of this product.

Best Deals from Liquid Fillers

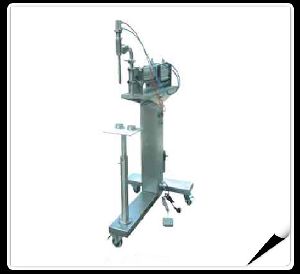

semi automatic liquid filler

Get Price Quote

Machine is fitted with: √ĘÄ¬Ę Electric motor, Gear box √ĘÄ¬Ę SS 304 Material to avoid rust / corrosion √ĘÄ¬Ę Height adjustable tray √ĘÄ¬Ę Peddle switch for manual filling system Probability of inaccuracy: +/- 2%

aesthetic treatment liquid neuramis hyaluronic acid dermal filler

6,000 Per Pack

Product Specifications   Usage/Application Professional Injectable Form Liquid Also Gives Third Party Manufacturing Dose 1.0mL Form Of Medicine Dermal Fillers Age Group Adults Gender Unisex Minimum Order Quantity 15 Box Delivery Time 2-3 Days Product Description   Neuramis Filler Hyaluronic Acid Dermal Filler are tissue recovering biomaterial. Treatment with Neuramis focuses on fixing fine lines and wrinkles and treating sunken areas on your facial area.     Expiry - 24 months from the manufacturing date Packaging Unit - 1.0mL Product Classification - single-use sterile medical device     Storage Condition 1. Store at 2 - 25 2. Do not freeze or heat the product 3. Avoid direct sunlight 4. Do not put any pressure or force on the product     It come under three types of version   1. Neuramis normal 2. Neuramis volume 3. Neuramis Deep   we can supply botox and other dermal filler world widely for small order payment will be accepted

Hand Operated Liquid Filler

Get Price Quote

Manual Hand operated Liquid Filling machine, It is a small desktop type filling machine. It is applied to filling ointment or liquid into various containers manually. All contact parts of this machine are made of high quality stainless steel Its structure is simple, easily operation and maintenance free. User can easily adjust the filling volume, from 10ml to 200 ml.

Liquid and Paste Filler

85,000 - 145,000 Per

1 Piece (MOQ)

Automatic Gear Pump Base Liquid Filler

Get Price Quote

Liquid filling machine is majorely used for filling free flowing liquids.Liquid filling machine also known as liquid filler and liquid dispenser which is suitable to fill 1ml to 5000ml of any liquid in bottles,cans,jars,tubsLiquid filling is automatic filling machine runs of volumetric filling principle.Liquid filling machine is widely used for milk filling, bottle filling, jar filling, container filling,oil filling,ointment filling, shampoo filling, juice filling, liquor filling, perfume filling, wine filling,can filling, food product filling. Filling by liquid filling machine is completely drip free and accurate in weight.Liquid filling machines are mostly used in pharmaceutical filling & food filling as a filler or dispenser Desired speed can be achieved by liquid filling machine bu adding filling heads Major liquid fillers are available in 2,4,6,8 headsLiquid Filling machine can produce 50-200 bottles per minute by adding maultiple heads to filler headVineger filling, perfume filling are used in liquid filling machine .Semi-Viscouse liquid can be accurately filled by liquid filler machine Lube oil filling machine & engine oil filling machine are catagories of liquid filling machine.Lots of lube oil filling & engine oil filling  companies adopt similar technology machine of liquid filling machine. Cosmetic shampoo filling & perfume filling machines are also fall in liquid filling machine category. Vineger filling machine is example of gravimetric liquid filling machine. Lots of wine filling & liquor filling are handle on our liquid filling machine. Spirit filling machine has similar design of liquid filling machine.Liquid packaging machine and packaging  machinery are majorely used on high speed liquid production industries. FEATURES: Accurate filling level control by diaphragm pump not necessary to adjust machine when filling volume changed. Suitable for wide range liquid characteristic even high viscosity. Touch screen control for easy graphical user interface. Automatically stopping machine system by detecting the shortage of bottles. All stainless construction meeting cG.M.P. requirements. Easy cleaning up,low maintenance.   APPLICATION :  Pharmaceutically liquid, chemical liquid, cosmetics, lotions, shampoos, sauces,syrups, oil, beverages,etc.  Capacity   10~70 bottles/min   Filling Volume  300~1500 ml(1500ml~5000ml also available for special order)   Filling Nozzles   2~12 Nozzles (depend on capacity & filling volume)   Compressed Air  3~6kg/cm2  Power Supply   AC 110/220V 60/50Hz Single Phase   Power Consumption  1/4 HP   Machine Weight  350 kg   Gross Weight  500 Kgs   Packing Size 2590mm x 870mm x 2300mm

Liquid Filler

Get Price Quote

CFM-0300K is a liquid filler which can be used even when it involves high difficulcy due to toxins and foams. ‚ÄĘ It is a liquid filler which can be used even when it involves high difficulcy due to toxins and foams. ‚ÄĘ Uses 2 level control value for high speed high precision ‚ÄĘ Nozzle has been designed for easy dismantling and cleaning ‚ÄĘ Can be used in explosive areas (EX dllB T4)

4 Nozzle Viscous Liquid Filler

Get Price Quote

DIGITAL LIQUID FILLER

20,000 Per Piece

1 Piece(s) (MOQ)

Abucks inc offers mini digital liquid filler that can fill all free flowing liquids which has specific gravity close to that of water with filling range from 2ml to 150ml this machine is extremely economical and compact model which requires small table space for filling liquids for household work, pharmaceutical or perfume filling, small production and r & d labs, the body of liquid filler is made of stainless steel and the dispensing pipe is made of rubber, this machine can be used to fill beverages, water, juices etc approximate filling speed is 5-6 bottles per minutes depends on the quantity and type of product . Salient features mini liquid filler is very compact and lightweight construction, can be easily moved around this bench top liquid filling machine contains 6 preset modes that can be calibrated for different volumes, therefore shifting from one container or material to another is very simple tiny or mini liquid filling machine is digital and easy to operate just plug and play device, can be up and running within 5-10 minutes mini liquid filler is made of stainless steel body, therefore protecting against corrosion mini liquid filling machine comes with a integrated auto mode switch which increases the speed of filling. mini digital liquid filler is provided with a digital counter which measures the number of bottles filled in a given time period, therefore it becomes easier for the operator to track production. Technical specification dimensions : l= 300 mm; w= 250 mm; h= 130 mm (12" x 10" x 5.1") weight : 5 kg (11 lbs.)approx fill range : 2 ml-150 ml power : 30 watts filling accuracy: +- 1%

Cross-linked Hyaluronic Acid Liquid Sardenya Filler

5,000 - 6,000 Per Box

Product Description ¬† ¬† ¬† DESCRIPTION: Sardenya is a Filler that is not derived from animals, which means it's safe for our skin. It's made up of 100% of stabilized cross-linked making the filler highly hydrating. ¬† Sardenya has an impressive visco-elasticity and flow. This is a huge advantage since you won't have to worry if your filler got deformed. ¬† One of the flagship benefits of using this filler is that it has a natural-looking effect due to its improved flow. If that's not enough benefit, it can also last for a long time. Which means you can save more money. ¬† It is highly recommended for those who have moderate to deep lines and folds since it can provide a good amount of volume. ¬† Benefits of Using Sardenya Fillers: ¬† Natural Looking One of the things most Sardenya users love about the brand is that it gives them a natural-looking result. You can thank its improved flow for this benefit. Not only will you be getting the nose, lips, cheeks, chin, or tight skin that you want, it will also be natural looking. ¬† Money-Saving ¬† Another great thing about these fillers is that it lasts for a long time, as compared to your regular fillers. If it lasts for a long time, you don't have to pay your doctor a visit every 3 ‚Äď 6 months. ¬† Safe for Use ¬† This filler is manufactured from Korea, which means it went through a thorough checking before it was approved. Plus, since this filler is non-animal based, it has gained quite an advantage. ¬† Highly Hydrating ¬† One great thing about fillers is that it can moisturize your skin. Hyaluronic acid attracts moisture, the absorbed moisture will then be forwarded to your skin. Giving your skin the hydration it needs.

Semi-auto liquid filler

Get Price Quote

Summarize: ¬°√īFilling precision can up to ¬°√Ä1% ¬°√īEasy to adjust filling volume ¬°√īEasy to operate,easy to maintain ¬°√īAdopt pneumatic and high quality elements ¬°√īWith manual and semi-automatic operation ¬°√īEasy to dismantle and install,easy to clean

Joint & Crack Liquid Pack Filler

35 Per Litre

500 Litre (MOQ)

HYPOL-Joint Pack is a newly devloped synthetic resin based two component self cure system of NON SHRINK & HARD filling compound for joint & cracks. Both powder and liquid is white coloured odourless and safe compound. Application :  As a joint filler for floor tiles of Ceramic, Marble, Granamite, Mosaic and Stone As a crack filler for Wall, Floor, and Ceiling. As a filler for gap between Frames and Wall.

Liquid Filler

Get Price Quote

We are Manufacturer and Supplier of this product. Mechanically operated AFFS machine to pack Free following Viscous liquids. PACKING RANGE - 100 ml to 500 ml. PACKING SPEED - 36 to 40 PPM. PACKAGING MATERIAL - LDPE TYPE OF SEALING - Center FILLING ACCURACY -+- 0.5% POWER CONSUMPTION - 3 HP MODEL - FFP LF

LIQUID CUM CREAM FILLER

Get Price Quote

A compact, single nozzle or double nozzle, semi-automatic piston liquid filler for liquid, cream, paste, and other viscous products dispensed in different capacities. Compact size makes it ideal for tabletop / bench-top operations for filling cosmetic and pharmaceutical products into tubes, pouches, and other small containers. Integral cutoff eliminates drips and product waste while saving the expense of separate cut-off accessories. SALIENT FEATURES Compact model Combined model for filling both liquid and paste Stainless steel construction Minimize wastage Machine is available in the range of 10 gm to 100 gm filling 100 gm to 1000 gm filling

Diving Nozzle Liquid Fillers

Get Price Quote

Semi Automatic Diving nozzle Liquid Filling Machine is versatile , single module machine for liquid and viscous material . Machine. Filling is based on the volume of the liquid pulled by stainless steel syringes moving in cyclical motion. Specially designed diving nozzle mechanism is ideal for forming liquid such as soap, Cleaner etc. At the start of the batch cycle , nozzle is entered inside the bottle or container and as the liquid is filled in to the container, nozlzle automatically pulled up resulting in near zero forming of liquid.

Sachet Packer Liquid Filler

Get Price Quote

Liquid Filler

Get Price Quote

For a packaging of variety of liquid and semi viscous liquid productsThe MK-212 is a Fully pneumatic vertical form fill seal packaging machine designed to package free flowing liquid products. This Fully automatic vertical Vffs packaging machine uses volumetric piston filler system to produce center sealed, 3 side sealed and 4 side sealed pouches / bags.Adding to its versatility, the 200-PL series can be integrated with most filler for granules, liquids, pastes, sticky powders, snacks and food grains etc. Application: Shampoo, oil, liquor, vodka, gin, water, agricultural liquid, Tomato Ketchup, mayonnaise, sauces etc. Features: Delta / Mitsubishi PLC and touch screen HMI controls. PLC (Programmable Logic control) Based. Brake motor mechanism used for laminated material pulling Motor for unwinding assembly. Integrated PID temperature controlled for precise temperature control Alternate filling systems:The PL 200 series VFFS packaging machines can be fitted with any one of the following fillers/ dosing systems Volumetric cup (telescopic) volumetric Piston filler Volumetric Paste filling pump Servo auger filler Linear weigh filler

High Viscosity Liquid Filler

Get Price Quote

This filling system is ideal for liquids such as edible oil, liquid chocolate, araldite which require precise dozing and need to be adjusted for various package sizes. The Filling valves give a positive settable volume dose of the product to be filled. The dose is accurate up to ¬Ī2 ml/grams on the set volume. The volume dosing piston is controlled and moved by cam track or by air cylinder. There is a No Bottle-No fill system in place to prevent any wastage. The bottles are raised to the filling nozzle by positive lift cylinder, if the bottle is not delivered the valve does not open. The product will be filled to preset volume and the bottle is lowered. The tank and all rubber components are designed to work at high temperatures. The filling valve is designed with a wide mouth arrangement that it may also be used for filling products with natural pulp/sacs in the liquid. The product is dropped down directly instead of flowing along the sides of the bottle, this prevents and shrinkage and warping in the bottle.